Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

Strong commitment to high quality standards

ZhuFa Advanced Ceramics' products are widely applied across a range of high-end manufacturing and cutting-edge technology industries. With outstanding properties such as wear resistance, corrosion resistance, high strength, and thermal stability, our ceramics have earned strong recognition from global clients. In the semiconductor sector, ceramic components are used for precision positioning, insulation, and heat dissipation in chip manufacturing. In the medical field, biocompatible and corrosion-resistant ceramics are ideal for surgical instruments and dental tools. In the new energy and laser industries, ceramic structural parts provide critical support and insulation under high pressure and extreme temperatures. Additionally, ZhuFa's products play a key role in automation equipment, military applications, and precision instruments—helping customers enhance performance and achieve reliable, long-term solutions in demanding environments.

-

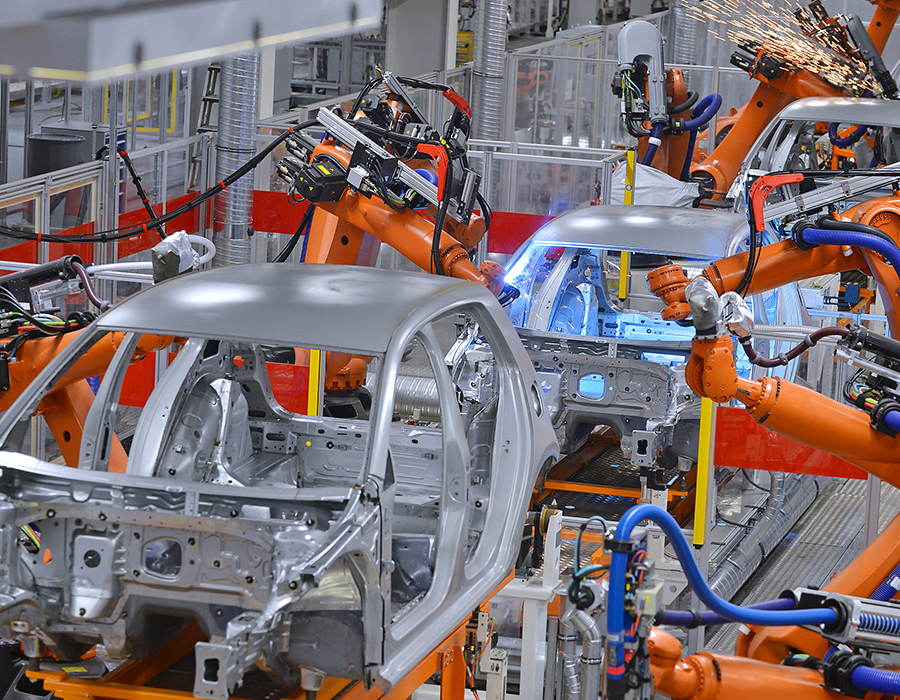

Automotive Industry

Widely used in engines, sensors, fuel cells, braking systems and electronic control units. With its excellent wear resistance, high temperature resistance and insulation performance, it effectively improves the performance, safety and durability of automobiles, and helps the development of new energy and smart cars. -

Photovoltaic Industry

Used for photovoltaic equipment and process links, such as wafer cutting, coating and high-temperature sintering. With its excellent high temperature resistance, wear resistance and insulation performance, it effectively improves production efficiency, extends equipment life, and ensures stable operation in harsh environments. -

Petrochemical

Widely used in petrochemical equipment such as pumps, valves, seals and reactors. With its excellent wear resistance, corrosion resistance and high temperature resistance, it ensures reliable operation of the equipment in complex chemical environments, reduces maintenance costs, and extends service life. -

Semiconductor Industry

It is used in wafer handling, etching, deposition and detection equipment. Its high purity, insulation, wear resistance and thermal stability help ensure process accuracy, reduce pollution risks, and improve equipment reliability. -

Medical Industry

Widely used in surgical instruments, implants, diagnostic equipment and fluid systems. Its excellent biocompatibility, wear resistance, corrosion resistance and insulation properties ensure the safety, precision and long-term stability of medical devices. -

Aerospace

Applied to aircraft engines, structural components, sensors and electronic systems. With high strength, lightweight, high temperature resistance and excellent insulation performance, it effectively improves fuel efficiency, reliability and safety, and ensures stable operation in extreme environments. -

Food Industry

Pumps, valves, nozzles and seals used in food processing equipment. With its excellent wear-resistant, corrosion-resistant and non-toxic hygienic characteristics, it ensures food safety, extends equipment life, and improves processing efficiency. -

Mechanical Equipment Industry

Widely used in various industrial machinery, such as bearings, tools, nozzles, guides and wear-resistant components. With high hardness, wear resistance and thermal stability, it effectively improves equipment performance, reduces downtime, and extends service life. -

New Energy Industry

Precision ceramics are used in lithium batteries, fuel cells, hydrogen energy and wind power systems. With excellent insulation, thermal stability and corrosion resistance, it effectively improves energy conversion efficiency, ensures safe operation, and helps the sustainable development of green energy technology. -

Textile Industry

Yarn guides, porcelain eyes, rollers and nozzles used in textile machinery. With its excellent wear resistance, smoothness and anti-static characteristics, it ensures high-speed and stable operation of the equipment, reduces yarn breakage rate, and improves textile quality. -

Biotechnology

It is used in bioreactors, analytical instruments, pumps and fluid systems. With high purity, corrosion resistance, insulation and good biocompatibility, it ensures the safety, precision and long-term reliability of biotechnology research and development and production processes. -

Intelligent Manufacturing

It is used in robots, automation systems, sensors and high-end production equipment. With excellent wear resistance, thermal stability and insulation performance, it effectively improves equipment accuracy, reliability and durability, and helps the development of smart factories and digital manufacturing.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어