Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

Alumina Ceramics: Key Insights into Manufacturing, Performance, and Industrial Applications?

What Core Characteristics Make Alumina Ceramics a Go-To Material for Precision Industries?

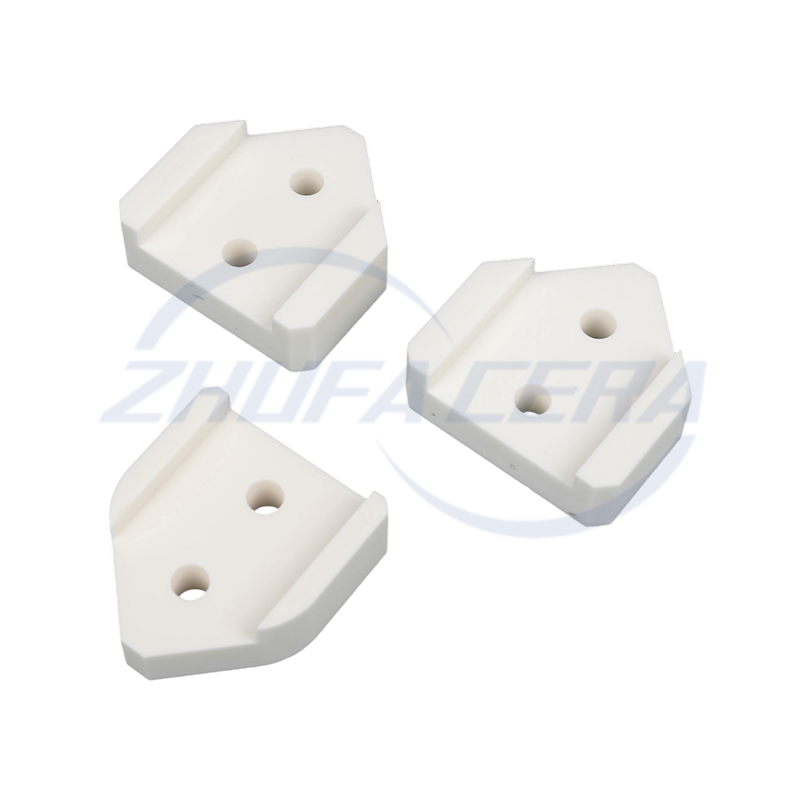

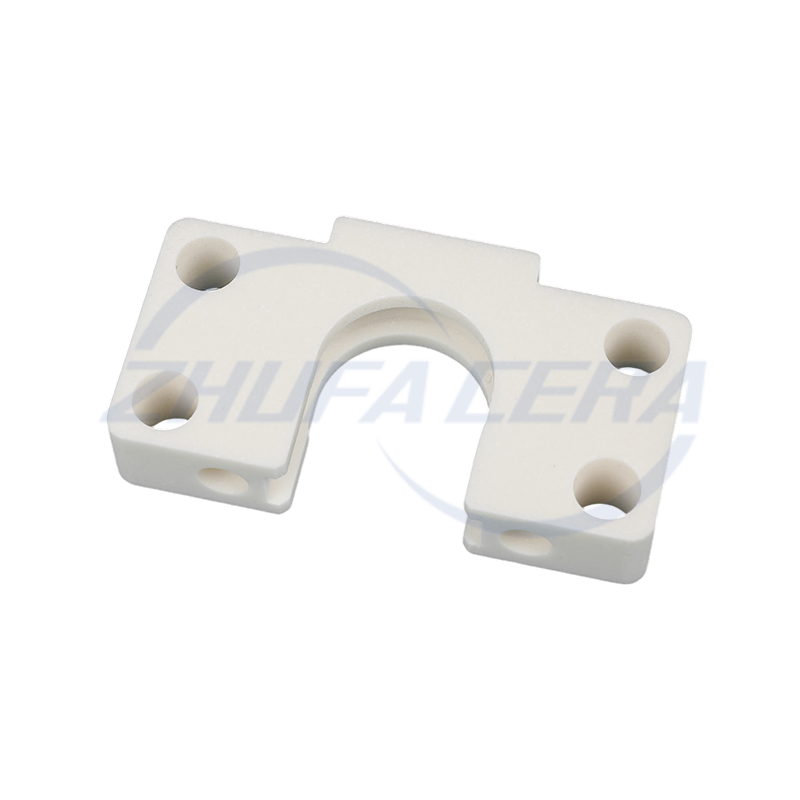

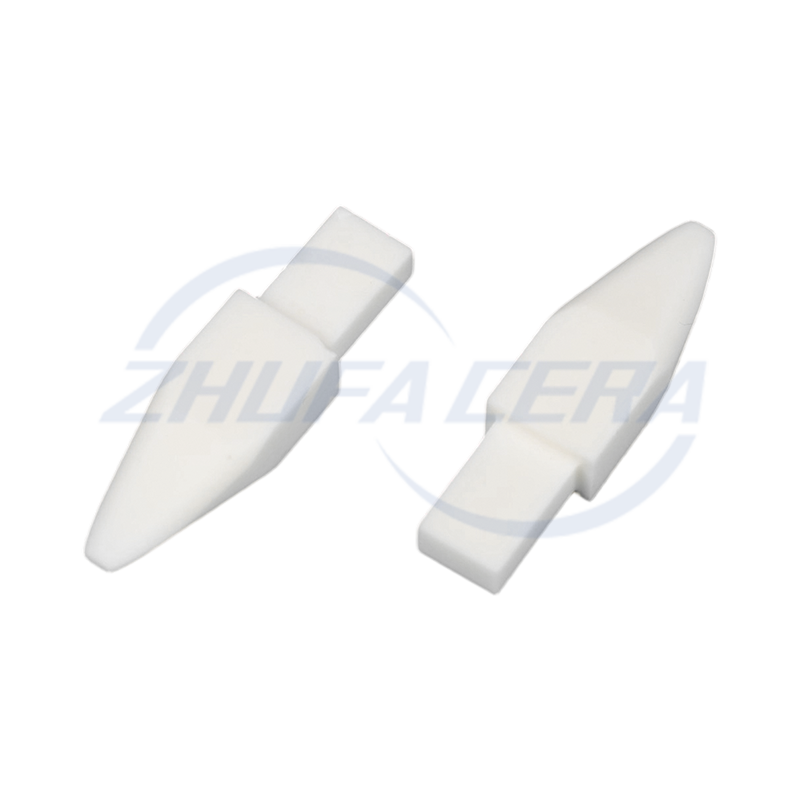

Alumina ceramics, primarily composed of aluminum oxide, stand out as a cornerstone of advanced ceramic materials due to their exceptional inherent properties. These include high hardness (second only to diamond among common industrial materials), excellent electrical insulation, resistance to high temperatures (withstanding over 1,600°C in many cases), and strong corrosion resistance against most chemicals. For manufacturers focused on precision components, these traits are non-negotiable—and Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. amplifies these advantages through strict process control. As a source factory specializing in new ceramic materials, the company ensures each alumina ceramic part retains consistent performance, aligning with industrial demands for reliability in harsh operating environments.

How Does Modern Manufacturing Ensure High-Quality Alumina Ceramics?

The manufacturing of alumina ceramics is a precision-driven process, with each step directly impacting final product quality. The typical workflow includes raw material purification (to reduce impurities that weaken performance), forming (such as dry pressing, cold isostatic pressing, or injection molding for complex shapes), high-temperature sintering (to achieve dense, stable ceramic bodies), and precision finishing (for tight dimensional tolerances).

Zhejiang Zhufa supports this workflow with a 30,000㎡ state-of-the-art manufacturing base, equipped with core machinery like high-temperature sintering furnaces, CNC engraving machines, and centerless grinders. This end-to-end in-house production capability—from raw material processing to final inspection—allows the company to control every detail, whether for standard alumina parts or non-standard, small-batch prototypes. By adhering to technology-driven standards, it ensures the alumina ceramics meet the strict precision and performance requirements of industrial clients.

Which Industrial Sectors Rely Heavily on Alumina Ceramics, and Why?

Alumina ceramics’ versatility makes them indispensable across multiple high-demand industries, with applications tailored to their unique strengths:

Automotive & New Energy: Used in sensors, braking systems, and electronic control units, their wear resistance and insulation improve vehicle safety and durability—key for new energy and smart car development.

Photovoltaics: Applied in wafer cutting and high-temperature sintering processes, their heat resistance and wear resistance boost production efficiency and extend equipment life.

Petrochemicals: Integrated into pumps, valves, and seals, their corrosion resistance ensures reliable operation in complex chemical environments, reducing maintenance costs.

Semiconductors: Utilized in wafer handling and etching equipment, their high purity and thermal stability minimize pollution risks and maintain process accuracy.

Zhejiang Zhufa leverages its cross-industry expertise to tailor alumina ceramic solutions for these sectors, supporting both small-batch trials and large-scale delivery to meet diverse client needs.

What Advantages Do Customized Alumina Ceramic Services Offer, and How Does Zhejiang Zhufa Deliver Them?

Industrial clients often require alumina ceramics tailored to unique shapes, sizes, or performance specs—standard off-the-shelf products rarely suffice. Customized services address this by aligning materials and design with specific application goals, such as optimizing for extreme temperatures or tight dimensional precision.

Zhejiang Zhufa excels in this area by offering fully in-house customization, direct engineering support, and flexible production (from small-batch proofing to mass manufacturing). Its customer-centric service system includes end-to-end support: from collaborating on design optimization to shorten development cycles, to ensuring consistent lead times. This approach not only meets clients’ performance and efficiency needs but also helps enhance their market competitiveness.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어