Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

1. Core New Ceramic Materials for Industrial Applications

New ceramic materials, distinct from traditional ceramics, are high-purity inorganic compounds engineered for targeted industrial performance. Their selection is dictated by application-specific requirements for mechanical strength, thermal stability, chemical resistance, and electrical properties—key factors that determine their suitability for end-use scenarios.

Alumina (Al₂O₃): Available in grades like 96%, 99.7%, and 99.95%, it delivers balanced performance with flexural strength ranging from 200-350 MPa, hardness up to 14 GPa, and temperature resistance exceeding 1600°C. Its excellent electrical insulation and wear resistance make it a versatile choice for electronic components (e.g., substrates) and mechanical parts (e.g., seals).

Zirconia (ZrO₂): Defined by ultra-high toughness (fracture toughness up to 17 MPa·m¹/²) and flexural strength reaching 1800 MPa, it stands out for thermal shock resistance. These traits make it ideal for demanding applications like automotive braking systems and precision structural components that require durability under rapid temperature changes.

Silicon Carbide (SiC) & Silicon Nitride (Si₃N₄): SiC offers exceptional hardness (28 GPa) and corrosion resistance, while Si₃N₄ provides superior thermal conductivity and fracture toughness. Both are critical for high-temperature industrial equipment, such as petrochemical reactors and engine parts, where stability under extreme conditions is non-negotiable.

Aluminum Nitride (AlN): Its standout feature is high thermal conductivity (up to 230 W/mK at 25°C) paired with electrical insulation—properties that make it a top choice for electronic heat management components, such as semiconductor heat sinks and LED packaging.

Suppliers like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. specialize in these materials, providing tailored solutions that align with industrial customers’ specific needs for performance, precision, and efficiency.

2. Standard Manufacturing Process of New Ceramic Parts

The production of new ceramic parts follows a rigorous, multi-stage workflow where each step directly impacts the final product’s quality and reliability. End-to-end control of these processes is critical for consistency, as demonstrated by facilities designed for full in-house manufacturing.

2.1 Raw Material Processing & Powder Preparation

This foundational stage determines material uniformity and long-term performance. Raw inorganic compounds are crushed, ground, and purified to produce fine powders, which are then mixed with binders and additives to enhance flowability (for shaping) and sintering behavior (for densification). For precision applications, powder particle size and homogeneity are strictly controlled—even minor variations can lead to defects like cracks or uneven density in the final component. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. integrates this step into its 30,000㎡ manufacturing base, ensuring raw material quality is maintained from the start of production.

2.2 Forming: Shaping the "Green Body"

Forming transforms processed powders into a pre-sintered "green body" (a fragile, porous structure) with the approximate shape of the final part. The choice of forming technique depends on the part’s complexity, size, and precision requirements:

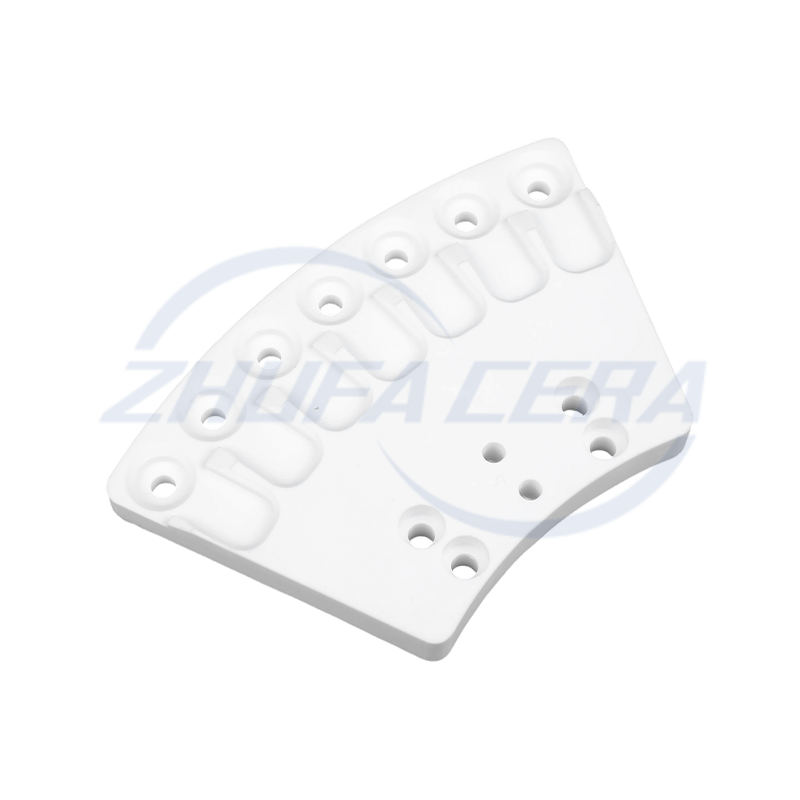

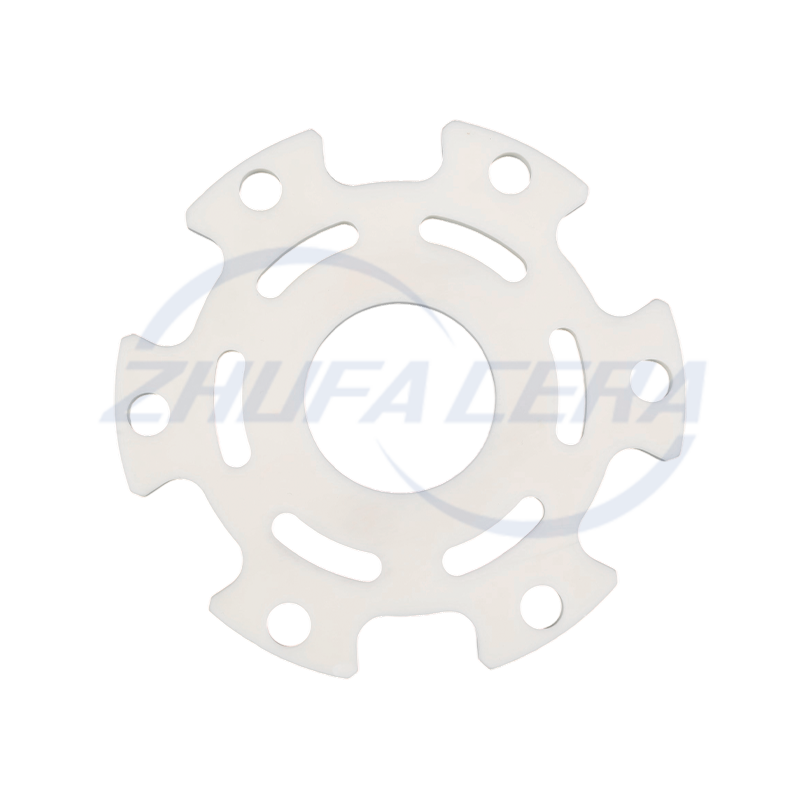

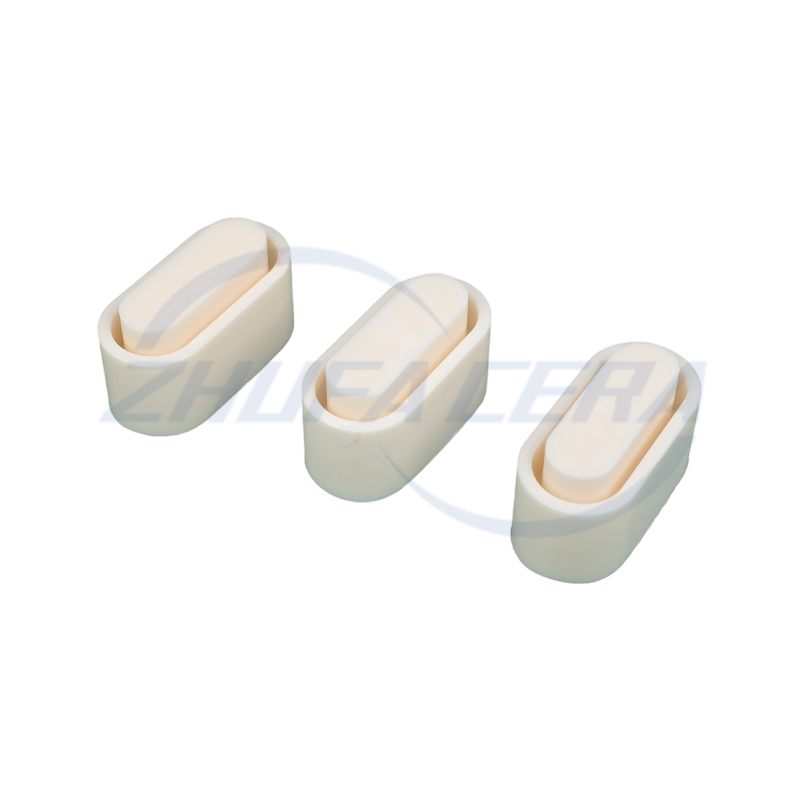

Dry Pressing & Cold Isostatic Pressing: Used for simple shapes like plates, rods, or washers, these methods apply uniform pressure (via presses or fluid-filled chambers) to compact powders, ensuring initial density and shape consistency.

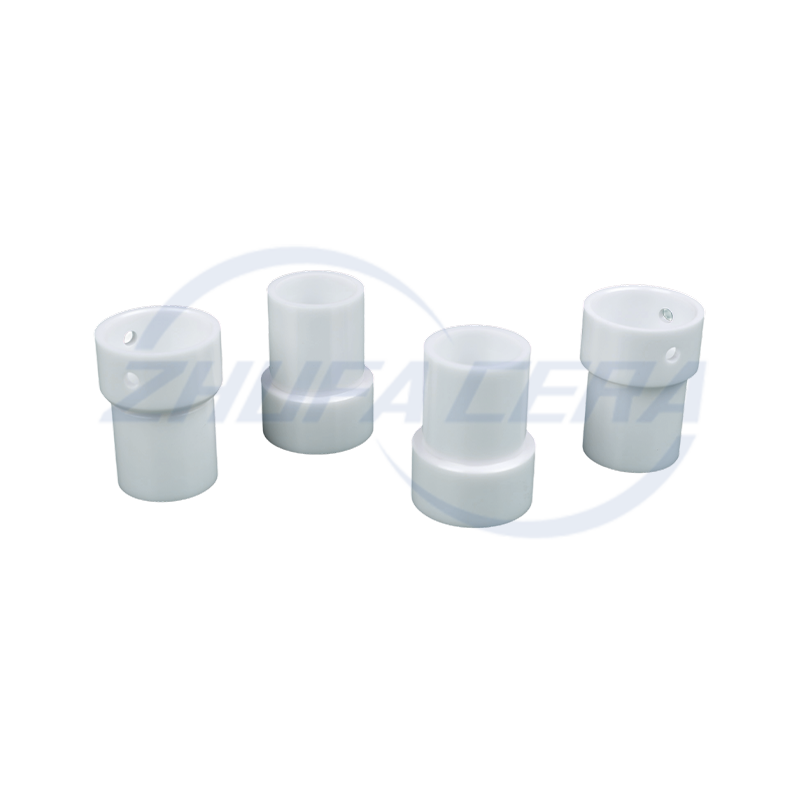

Injection Molding: Ideal for complex, intricate components (e.g., small sensor housings or turbine blades), this process injects a powder-binder mixture into precision molds, allowing for detailed features and tight initial tolerances.

Advanced facilities like that of Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. equip their production lines with all these techniques, enabling them to accommodate both standard designs and non-standard, custom parts.

2.3 Sintering: Densification & Property Development

Sintering is the heat treatment process that converts the fragile green body into a dense, functional ceramic. It occurs in two key phases:

Preheating (up to 250°C): Removes organic binders and volatile components from the green body—this step is critical to prevent cracking or bubbling during high-temperature heating.

High-Temperature Sintering: The preheated green body is heated to material-specific temperatures (typically 1200-1750°C, depending on the ceramic). At this stage, powder particles fuse together, reducing porosity and developing the material’s final mechanical, thermal, and electrical properties. Shrinkage during sintering (usually 10-20%) must be precisely calibrated in the design phase to ensure the final part meets dimensional requirements.

High-temperature sintering furnaces with precise temperature control are essential here—their stability ensures consistent densification. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. prioritizes this step to guarantee that every ceramic product meets performance and reliability standards.

2.4 Precision Finishing & Quality Inspection

Post-sintering processing refines the part’s dimensions, surface quality, and functionality to meet industrial precision standards (often requiring tolerances as tight as micrometers). Common equipment used in this stage includes CNC engraving machines (for detailed features), surface grinders (for flatness), centerless grinders (for cylindrical parts), and honing machines (for internal holes).

Quality inspection is integrated throughout finishing to verify:

Dimensional accuracy: Using tools like coordinate measuring machines (CMM) to check if the part matches design specifications.

Material properties: Testing hardness (via Vickers or Rockwell methods), flexural strength, thermal conductivity, or electrical insulation to confirm performance.

Microstructural integrity: Using microscopes to detect internal defects like voids or cracks that could compromise durability.

Strict quality control at this stage is non-negotiable—Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. incorporates this into its workflow to ensure every component meets or exceeds customer expectations.

3. Practical Considerations for Custom Ceramic Part Manufacturing

3.1 Material-Selection Guidelines

Choosing the right ceramic material requires balancing three key factors: performance needs, cost, and manufacturability. For example:

If an application demands balanced insulation, wear resistance, and cost-effectiveness (e.g., electronic substrates or mechanical seals), alumina is often the optimal choice.

For parts requiring ultra-toughness and thermal shock resistance (e.g., automotive braking systems or medical instruments), zirconia is preferred.

When high thermal conductivity and electrical insulation are critical (e.g., semiconductor heat sinks or LED packaging), aluminum nitride is the go-to material.

For harsh chemical environments (e.g., petrochemical pumps) or high-wear applications (e.g., photovoltaic wafer cutting tools), silicon carbide’s corrosion resistance and hardness make it ideal.

Suppliers with cross-industry expertise, such as Zhejiang Zhufa Precision Ceramics Technology Co., Ltd., often provide direct engineering support to help customers optimize material selection for their specific use cases, avoiding over-specification (which increases costs) or under-performance (which risks failure).

3.2 Navigating Customization: Small Batches to Mass Production

Industrial customers frequently require non-standard parts (e.g., custom sensor housings or unique pump seals), making flexible manufacturing capabilities a key consideration. When partnering with a supplier for custom parts, focus on three priorities:

Prototype Validation: Small-batch proofing (typically 10-50 parts) allows testing of both design feasibility (e.g., do complex features hold up during sintering?) and material compatibility (e.g., does the ceramic withstand the end-use environment?). This step reduces the risk of costly errors when scaling to larger production runs.

Process Adaptability: Complex parts may require combining forming techniques—for example, using injection molding for detailed features, then post-sintering CNC machining to refine tight tolerances. Suppliers with diverse in-house equipment (like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd.) can adapt processes to match custom needs more efficiently than those relying on external subcontractors.

Lead Time Management: In-house manufacturing streamlines workflows by eliminating delays from third-party suppliers. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. leverages its integrated 30,000㎡ facility to offer rapid prototyping (often 2-4 weeks for small batches) and consistent large-scale delivery, ensuring customers meet their production timelines.

3.3 Aligning with End-Use Industry Requirements

Different sectors demand specialized ceramic properties, and manufacturing processes must be tailored to these needs to ensure optimal performance:

Automotive & New Energy: Parts like engine components or fuel cell parts require high wear resistance and thermal stability. Manufacturers prioritize materials like zirconia (for braking systems) and silicon nitride (for engine parts) and use precision finishing to ensure tight tolerances that prevent leaks or premature wear.

Semiconductor & Electronics: High purity (to avoid contamination) and electrical insulation are critical. Materials like alumina (for substrates) and aluminum nitride (for heat sinks) are processed in clean environments, with strict quality checks to ensure no impurities compromise semiconductor manufacturing processes (e.g., etching or deposition).

Petrochemical: Equipment like pumps, valves, and reactor parts need extreme corrosion resistance and high-temperature stability. Silicon carbide is the material of choice here, and manufacturing focuses on achieving smooth surfaces (to reduce chemical buildup) and dense microstructures (to prevent fluid penetration).

Photovoltaic: Wafer cutting, coating, and sintering processes require ceramics with high wear resistance and thermal stability. Alumina and silicon carbide parts are used here, with finishing steps that ensure dimensional consistency to maintain precision in solar cell production.

By aligning manufacturing processes with these industry-specific needs, suppliers can deliver parts that directly improve their customers’ product performance—whether that’s longer equipment life (for petrochemicals), higher energy efficiency (for new energy vehicles), or more reliable semiconductor production.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어