Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

Silicon Carbide Ceramics: Practical Manufacturing & Application Insights

What Core Properties Make Silicon Carbide Ceramics Indispensable for Industrial Use?

Silicon carbide ceramics stand out in advanced ceramic materials due to a unique combination of performance characteristics that address critical industrial pain points. Chemically stable with a molecular formula of SiC, it exhibits exceptional mechanical strength—boasting a flexural strength of 400-600 MPa and a Mohs hardness of 9.2, second only to diamond—making it highly resistant to wear and impact. Its thermal properties are equally remarkable: it can withstand temperatures up to 1600℃ in oxidizing environments and has a low thermal expansion coefficient (3.5-4.8×10⁻⁶/℃), ensuring minimal deformation even under rapid temperature fluctuations. Additionally, it offers excellent electrical insulation (volume resistivity >10¹² Ω·cm at room temperature) and corrosion resistance to most acids, alkalis, and molten salts, except for strong oxidizing acids like concentrated nitric acid.

These properties align with the diverse needs of industrial customers for performance, precision, and efficiency—requirements that Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. addresses through its customized advanced ceramic solutions, which include silicon carbide alongside other materials like zirconia and alumina. For applications demanding durability in harsh conditions, SiC ceramics’ inherent strengths make them a go-to choice, and manufacturers like Zhufa leverage these traits to develop components that outperform traditional metal or plastic alternatives.

What Key Steps Determine the Quality of Silicon Carbide Ceramic Manufacturing?

The manufacturing process of silicon carbide ceramics is a precision-driven sequence, with each step directly influencing the final product’s performance. Raw material preparation is the first critical stage: high-purity SiC powder (typically 99% purity or higher) must be uniformly mixed with sintering aids (such as boron carbide and carbon) to lower the sintering temperature and improve densification. Uneven mixing can lead to voids or inconsistent grain growth, compromising strength.

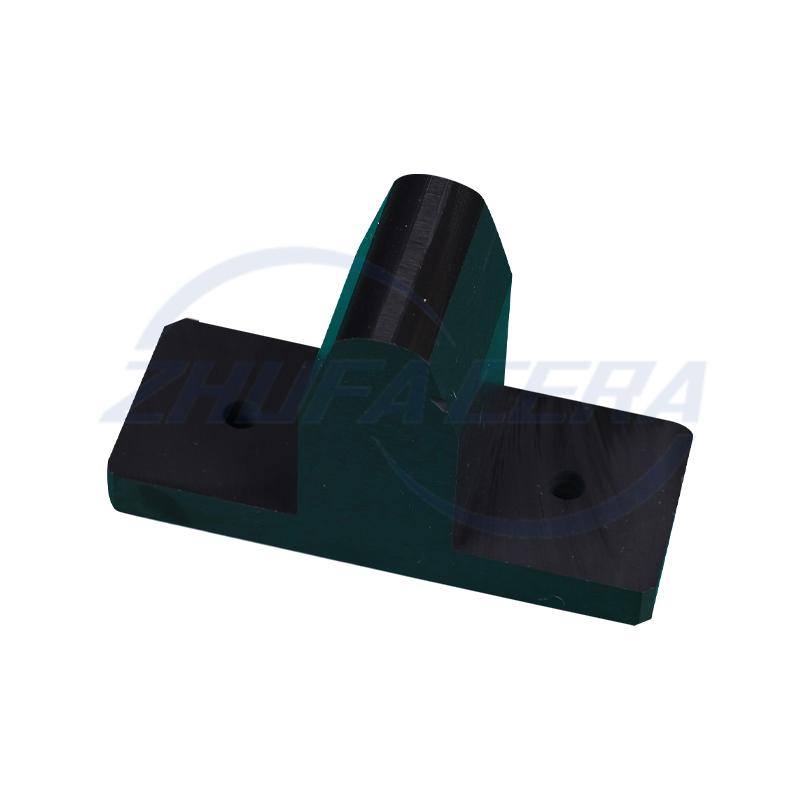

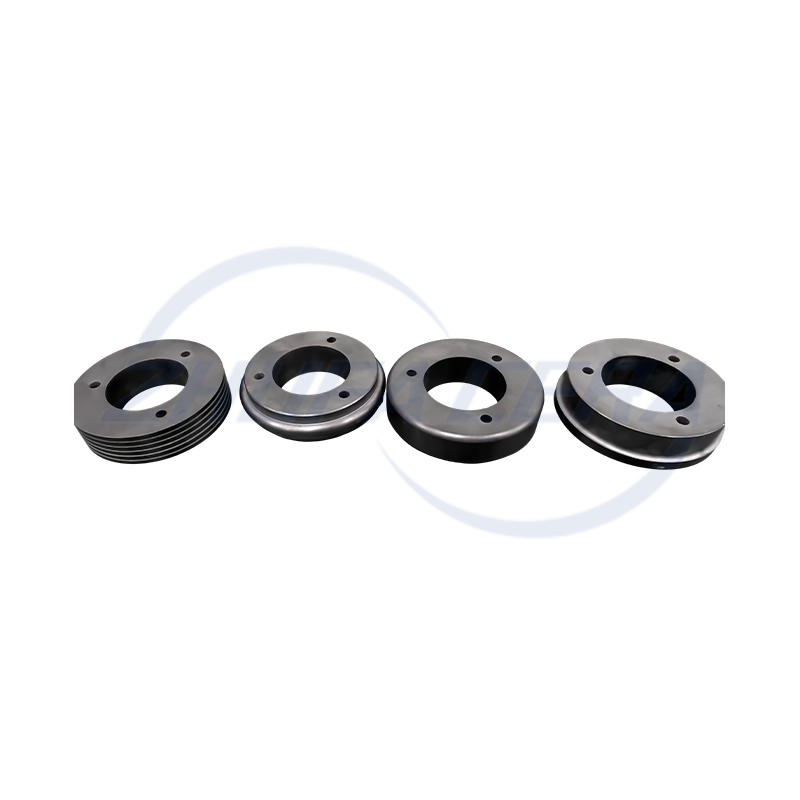

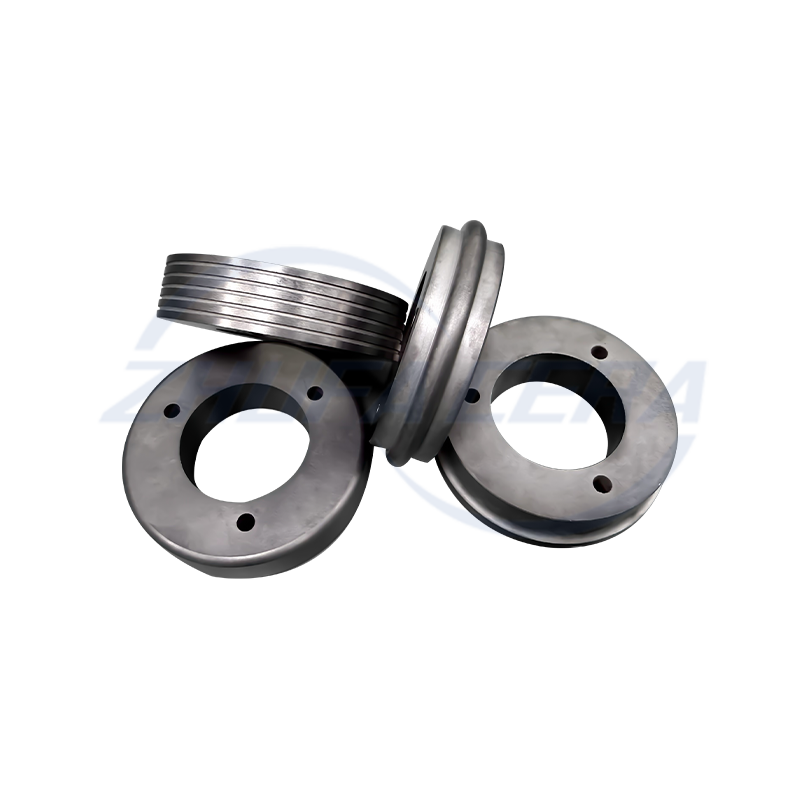

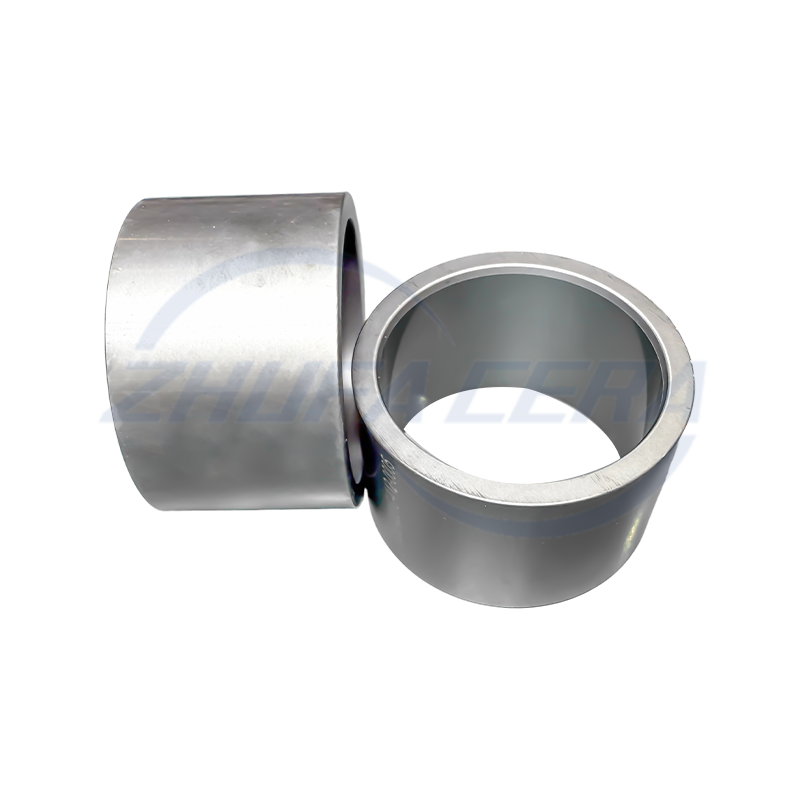

Next, molding methods are selected based on component shape and precision requirements. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. utilizes advanced equipment like dry pressing, cold isostatic pressing, and injection molding in its 30,000㎡ manufacturing base to cater to different needs: dry pressing is ideal for simple shapes (e.g., washers, plates) with high production efficiency; cold isostatic pressing ensures uniform density for complex structural parts; injection molding enables the creation of intricate components like semiconductor wafer handling fixtures.

Sintering is the most critical step, requiring high-temperature furnaces (1900-2200℃) and precise atmosphere control (often argon or vacuum) to avoid oxidation. Even a 50℃ deviation from the optimal sintering temperature can reduce the material’s relative density from over 95% (required for industrial use) to below 90%, drastically lowering its mechanical performance. Post-sintering finishing, using CNC engraving machines, surface grinders, and centerless grinders—equipment that Zhufa also equips its facility with—ensures dimensional precision (up to ±0.005mm) and smooth surface quality, meeting the strict standards for precision structural components.

How to Match Silicon Carbide Ceramic Components to Specific Industrial Applications?

Selecting the right silicon carbide ceramic specifications for an application requires aligning the material’s properties with the industry’s unique operating conditions. Here are practical adaptation guidelines for key sectors:

Automotive Industry: For engine parts, fuel cell components, and braking systems, SiC ceramics’ high-temperature resistance and wear resistance reduce component degradation. For example, SiC seals in automotive water pumps withstand 120-150℃ temperatures and frequent friction, improving the pump’s service life by 3-5 times compared to rubber seals. Zhejiang Zhufa Precision Ceramics supports non-standard processing for such automotive components, ensuring they fit specific engine or braking system designs while enhancing safety and durability—key factors in new energy and smart car development.

Photovoltaic Industry: In wafer cutting and high-temperature sintering processes, SiC ceramic parts (e.g., cutting blades, sintering trays) resist the abrasive wear of silicon wafers and maintain stability at 800-1200℃. Their low thermal expansion coefficient prevents tray warping, ensuring consistent wafer positioning and reducing production defects. Zhufa’s ability to provide small-batch proofing allows PV equipment manufacturers to test and validate SiC components before large-scale deployment, optimizing production efficiency.

Petrochemical Industry: Pumps, valves, and reactor internals made of SiC ceramics withstand corrosive media like sulfuric acid and hydrochloric acid at 200-500℃. For instance, SiC valve cores in chemical pipelines reduce leakage risks and extend maintenance intervals from 6 months (for metal cores) to 2 years. Zhufa’s cross-industry expertise helps petrochemical clients select the right SiC grade (e.g., reaction-bonded vs. sintered SiC) based on their specific chemical environment, ensuring reliable operation.

Semiconductor Industry: Wafer handling and etching equipment require SiC ceramics with high purity (99.9% or higher) to avoid contamination. Their insulation and thermal stability prevent electrostatic damage to wafers and ensure consistent performance during deposition processes. Zhufa’s in-house manufacturing capabilities, from raw material processing to precision finishing, enable the production of ultra-pure SiC components that meet semiconductor industry standards for cleanliness and precision.

What Quality Control Measures Ensure Consistent Performance of Silicon Carbide Ceramics?

Consistency in silicon carbide ceramic performance relies on strict quality control (QC) throughout the manufacturing cycle—an area where Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. adheres to strict control standards. Raw material QC involves testing powder purity via X-ray fluorescence (XRF) and particle size distribution using laser diffraction, ensuring no impurities exceed 0.1% (which could weaken the final product).

During sintering, real-time temperature monitoring with thermocouples and atmosphere control systems prevents oxidation or incomplete densification. Post-production testing includes measuring relative density via the Archimedes method (requiring ≥95% for industrial use), flexural strength testing with a universal testing machine, and dimensional inspection using coordinate measuring machines (CMMs) to verify precision. For corrosion-resistant applications, samples undergo 1000-hour immersion tests in target media to confirm no weight loss or structural damage.

Zhufa’s well-structured production workflow and QC system ensure that even for non-standard or small-batch orders, each silicon carbide component meets performance and reliability requirements. This attention to detail is critical for industrial customers, as inconsistent ceramic quality can lead to equipment downtime, increased maintenance costs, and compromised safety—risks that strict QC mitigates.

Why Choose Custom Silicon Carbide Services, and What Advantages Do They Offer?

For many industrial applications, off-the-shelf silicon carbide components fail to meet unique size, shape, or performance requirements—making custom services a practical necessity. Providers like Zhejiang Zhufa Precision Ceramics offer key advantages that address these needs:

Fully in-house manufacturing eliminates reliance on third-party suppliers, reducing lead times and ensuring better control over production quality. Low-volume & multi-type capabilities allow for small-batch proofing (even 1-10 pieces), enabling clients to validate designs without large upfront investments. Direct engineering support helps optimize component design—for example, adjusting a SiC pump impeller’s geometry to improve fluid flow while maintaining structural strength—reducing costs and shortening development cycles.

Zhufa’s customer-centric approach, which includes full-process services from prototyping to large-scale production, ensures that custom silicon carbide components align with clients’ exact specifications. This flexibility is particularly valuable for industries like new energy vehicles or semiconductors, where unique component designs are often required to improve equipment performance. By leveraging custom services, clients can enhance their own market competitiveness while benefiting from the inherent strengths of silicon carbide ceramics.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어