Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

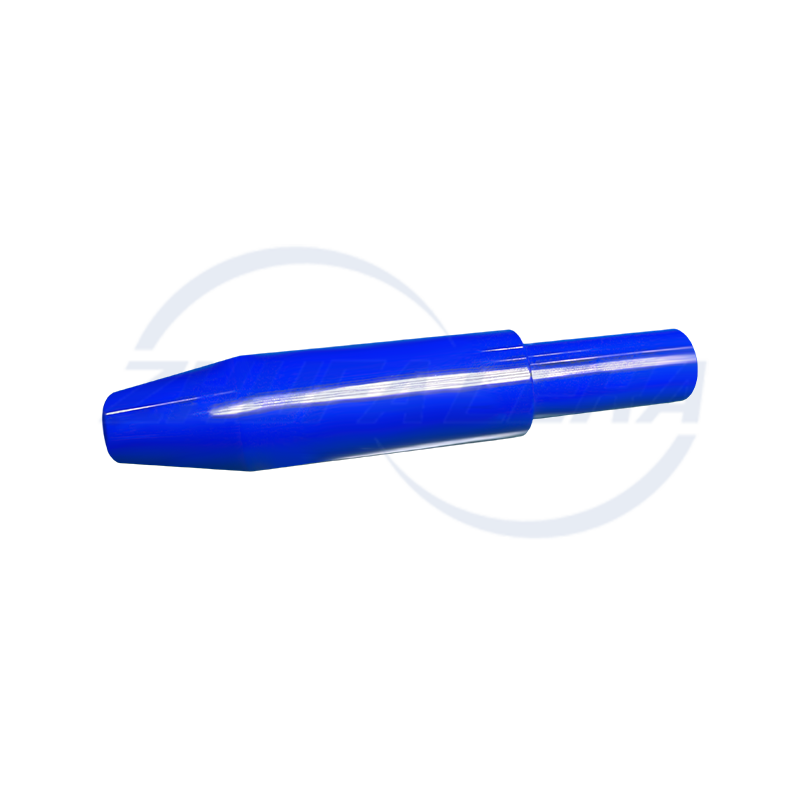

Focus on Blue Zirconia Ceramic: Practical Manufacturing Insights

How Is High-Quality Blue Zirconia Ceramic Powder Prepared Industrially?

The foundation of reliable blue zirconia ceramic lies in its powder preparation, a process that directly determines color uniformity and mechanical performance. Industrial production typically adopts a co-precipitation method optimized for consistent pigment dispersion, addressing the common issue of uneven coloring caused by pigment aggregation or volatilization.

Key steps include dissolving zirconium oxychloride, soluble yttrium salts (e.g., yttrium chloride), aluminum salts (e.g., aluminum nitrate), and cobalt salts (e.g., cobalt chloride) in deionized water at a precise molar ratio—usually Zr⁴⁺:Y³⁺:Al³⁺:Co²⁺ = 100:3~6:4~16:2~8 . A dispersant like ethylene glycol or dimethylformamide (0.1%~0.5% of the solution mass) is added and stirred for 3-5 hours to ensure homogeneous mixing . Ammonia solution (25%) is then dripped in until the pH reaches 10.0 to form precipitates, which are aged for 24 hours, washed with water and ethanol, and dried at 80°C . The final critical step is pre-calcination at 1180°C for 3-8 hours to obtain stable blue zirconia powder with minimal pigment loss .

Facilities like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd., which specializes in advanced ceramic customization, integrate this powder preparation into their end-to-end production workflow, ensuring raw material consistency for subsequent processing.

What Core Processes Ensure Blue Zirconia Ceramic’s Structural Integrity?

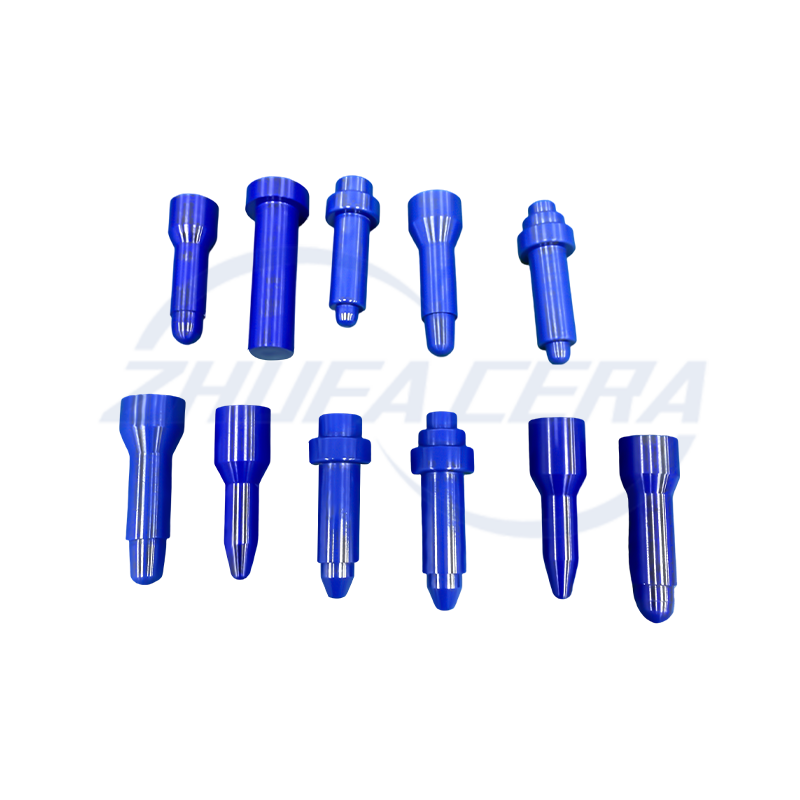

Transforming blue zirconia powder into high-performance components relies on three interconnected processes: molding, sintering, and precision finishing—each requiring strict parameter control to avoid defects like cracking or dimensional inconsistency.

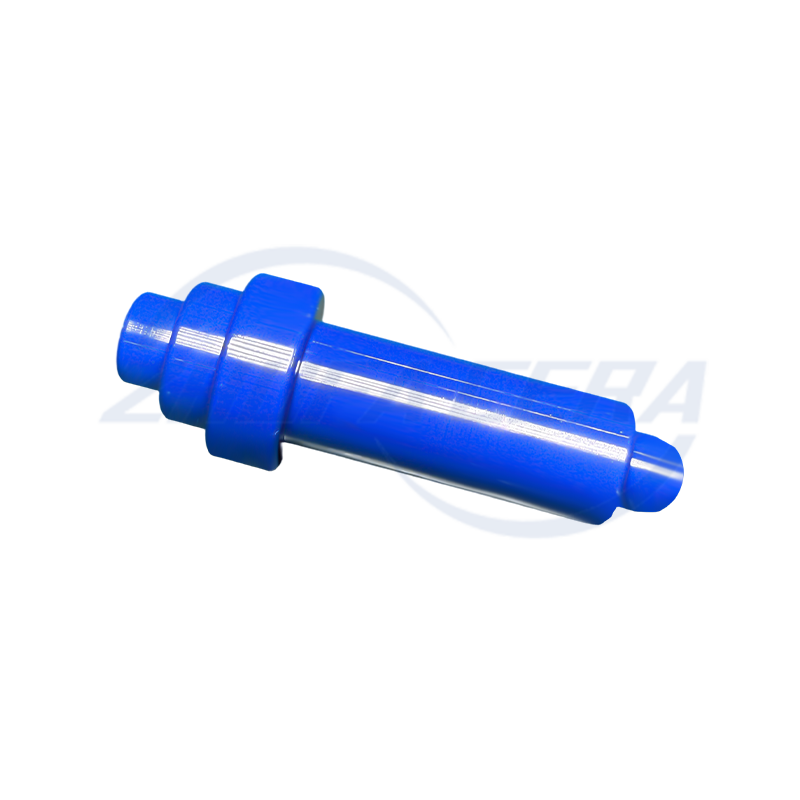

Molding begins with granulating the pre-calcined powder, followed by shaping via dry pressing or cold isostatic pressing . Cold isostatic pressing is preferred for complex structural parts as it distributes pressure evenly, reducing post-sintering shrinkage variations. Sintering then takes place at 1450~1550°C with 2~8 hours of heat preservation ; this high-temperature stage densifies the ceramic body while locking in the blue hue—critical for preventing color fading or unevenness.

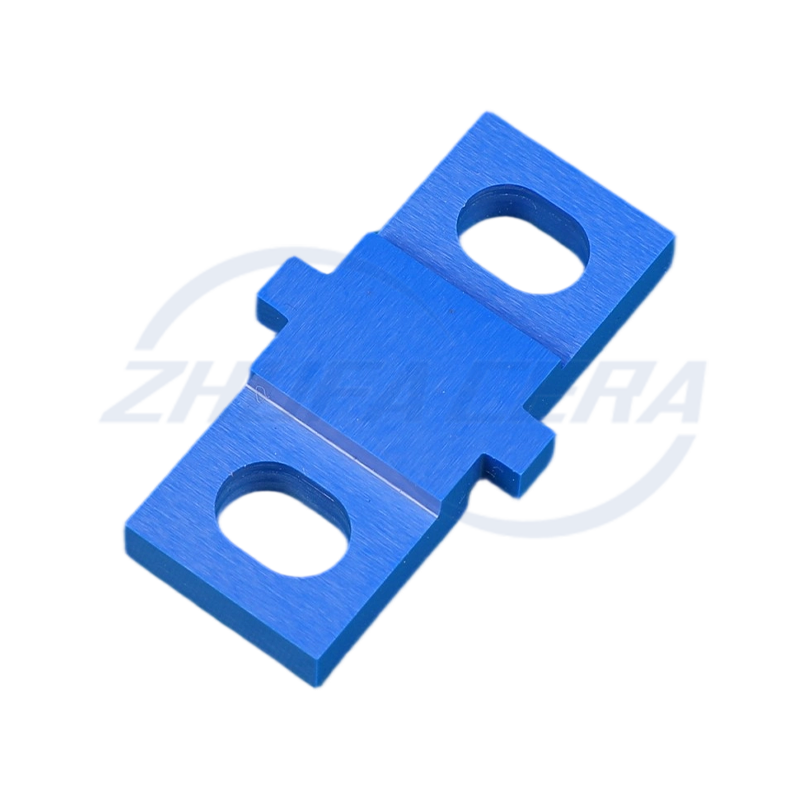

Post-sintering finishing is equally vital for industrial-grade precision. Manufacturers like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. use CNC engraving machines, surface grinders, and honing machines to achieve tight tolerances, essential for applications like automotive sensors or semiconductor wafer handling equipment. Their 30,000㎡ production base is equipped with these core machines, supporting both small-batch proofing and large-scale production of structurally sound components.

Which Technical Specifications Define Industrial-Grade Blue Zirconia Ceramic?

Industrial applications demand blue zirconia ceramic to balance aesthetic stability with functional performance, measured by four key technical specifications:

Fracture Toughness: For structural parts in automotive braking systems or petrochemical valves, fracture toughness of 8–12 MPa·m¹/² (typical for 3Y-TZP stabilized grades) is required to resist crack propagation under cyclic stress . This ensures durability in high-impact environments.

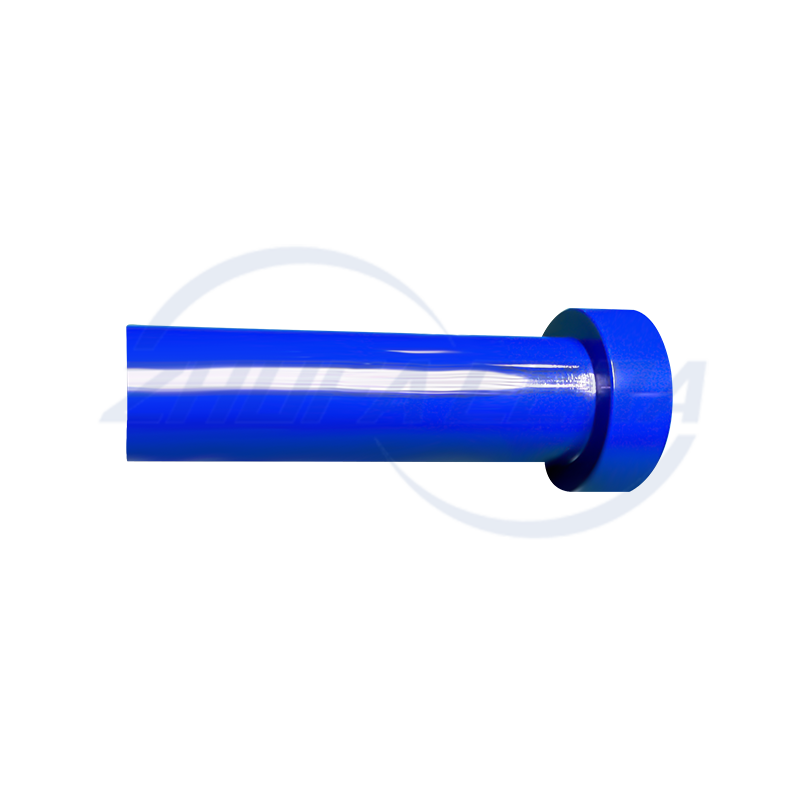

Density: Sintering at 1450~1550°C achieves dense ceramic bodies (≥6.0 g/cm³), which enhances corrosion resistance—critical for petrochemical reactors exposed to harsh chemicals .

Color Stability: The cobalt-aluminum pigment system must remain uniform and fade-resistant. Optimized co-precipitation (with Al³⁺:Co²⁺ = 2:1) prevents pigment volatilization during sintering, ensuring consistent blue tones .

Dimensional Accuracy: Precision grinding processes deliver tolerances within ±0.005mm, meeting the requirements of semiconductor wafer handling components where even minor deviations cause process errors.

Suppliers like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. align their quality control with these specifications, integrating strict testing into their production workflow to meet cross-industry demands.

How to Address Common Defects in Blue Zirconia Ceramic Manufacturing?

Defect control is critical for industrial usability, with three prevalent issues and proven solutions rooted in process optimization:

Color Inconsistency: Caused by uneven pigment dispersion or high-temperature volatilization. Solutions include using the co-precipitation method to encapsulate cobalt pigments in the zirconia matrix during pre-calcination , and maintaining stable sintering temperatures (±10°C) with advanced furnaces.

Cracking/Chipping: Arises from thermal shock during sintering or uneven pressure in molding. Manufacturers mitigate this by controlling heating/cooling rates (≤5°C/min) and using cold isostatic pressing for uniform compaction . Facilities like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. rely on well-structured workflows to minimize handling damage post-sintering.

Dimensional Variations: Stem from uneven shrinkage during sintering. Precision molding equipment (e.g., servo-driven dry presses) and post-sintering grinding with CNC machines resolve this, ensuring consistent dimensions across batches .

These solutions are integrated into the manufacturing systems of leading suppliers, supporting reliable production of blue zirconia ceramic for demanding industrial applications.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어