Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

What Exactly is Silicon Nitride Ceramics?

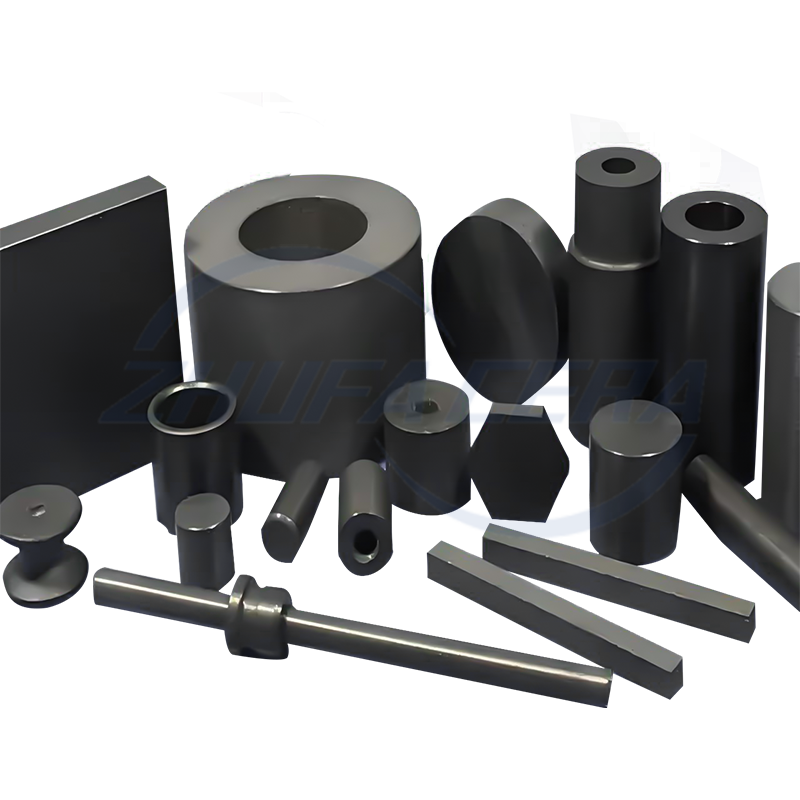

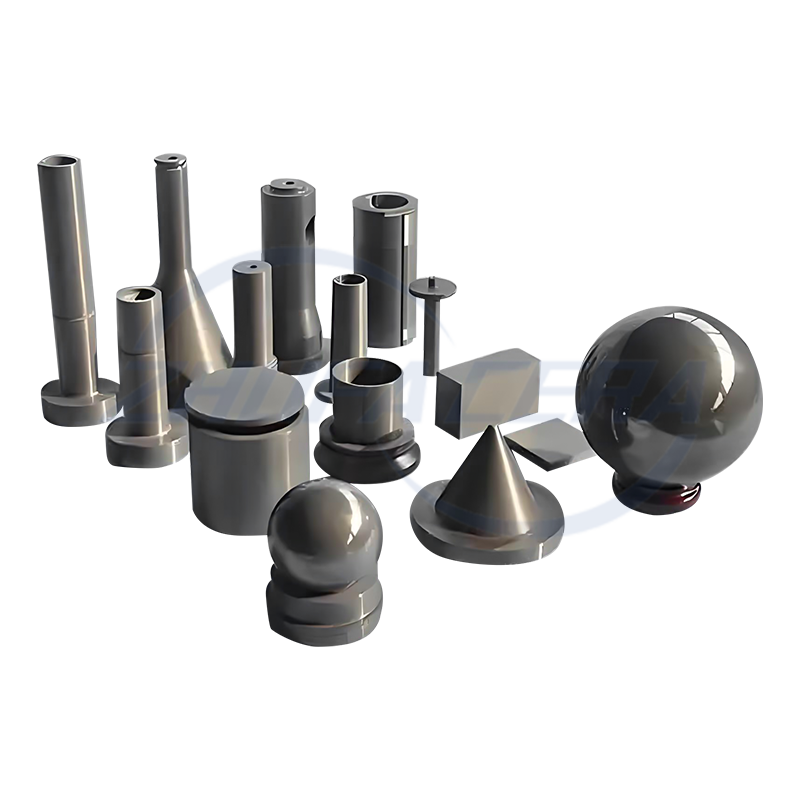

Silicon nitride ceramics are advanced ceramic materials with the chemical formula \(Si_3N_4\). They are formed by the combination of silicon (Si) and nitrogen (N) elements through covalent bonds, resulting in a hexagonal crystal structure. There are two main crystal forms: α - silicon nitride and β - silicon nitride. The unique crystal structure endows silicon nitride ceramics with a series of excellent properties. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd., as a professional precision ceramics manufacturer, has in - depth research and rich production experience in silicon nitride ceramics and other new ceramic materials. Their production process strictly controls every link to ensure the quality of silicon nitride ceramic products.

What Are the Striking Properties of Silicon Nitride Ceramics?

1. Mechanical Properties

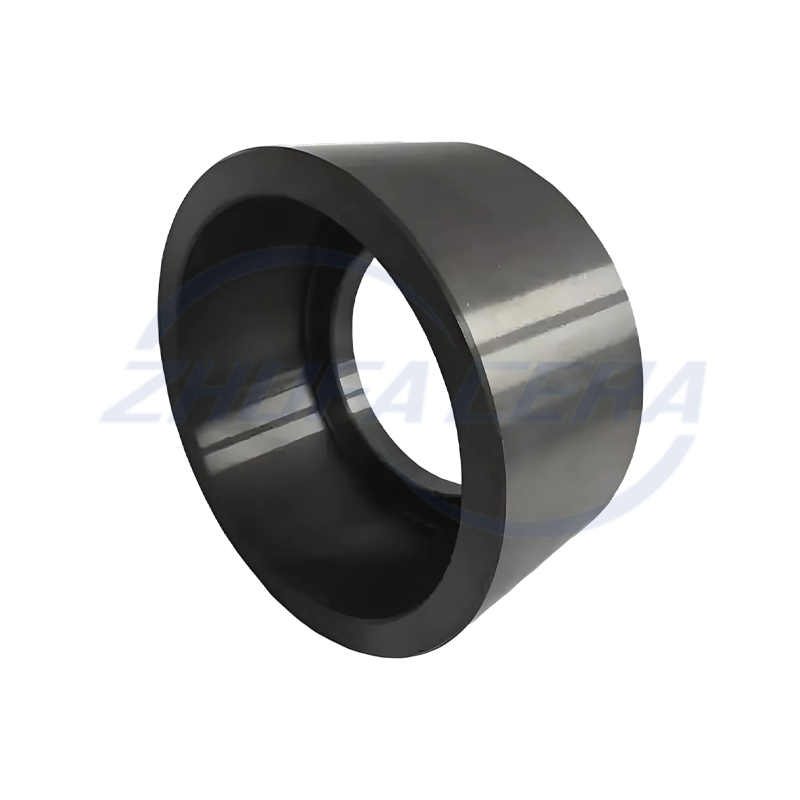

Silicon nitride ceramics are renowned for their remarkable mechanical properties. With a Mohs hardness of 9 - 9.5, they are extremely hard, second only to a few super - hard materials like diamond. This high hardness endows them with excellent wear - resistance, making them ideal for applications where components are subject to severe friction, such as in mechanical seals. Their bending strength ranges from 900 - 1200MPa, which is 2 - 3 times that of traditional ceramic materials. For example, traditional clay - based ceramics usually have a bending strength of only 300 - 400MPa. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. makes full use of these mechanical properties in the production of precision ceramic structural parts. Their strict production process ensures that the silicon nitride ceramic products maintain these high - level mechanical performances, meeting the high - demand applications in various industries.

2. Thermal Properties

In terms of thermal properties, silicon nitride ceramics have a high melting point of 2800℃, enabling them to maintain stability in extremely high - temperature environments. Their low coefficient of thermal expansion, about \(3.6Ã10^{-6}/â\), means that they experience minimal dimensional changes with temperature variations. This property is crucial for applications in engines and high - temperature furnaces. Additionally, they possess good thermal shock resistance, which allows them to withstand rapid temperature changes without cracking. For instance, in some high - temperature industrial processes where materials need to be rapidly heated and cooled, silicon nitride ceramics can perform stably.

3. Chemical Properties

Silicon nitride ceramics exhibit excellent chemical stability. They can resist the corrosion of most inorganic acids, such as hydrochloric acid and sulfuric acid. They can also tolerate the corrosion of some alkaline solutions, molten alkalis, and salts. In the petrochemical industry, pumps and valves made of silicon nitride ceramics can operate reliably in complex chemical environments, significantly reducing maintenance costs and extending the service life of equipment. This chemical stability makes them suitable for a wide range of chemical - related applications.

4. Electrical Properties

Regarding electrical properties, silicon nitride ceramics have an electrical conductivity of about \(10^{-4}S/cm\) and a dielectric constant of 9.5. These properties make them promising materials for use in electronic devices. For example, in some semiconductor manufacturing processes, silicon nitride ceramics can be used in wafer handling, etching, deposition, and detection equipment. Their high purity, insulation, wear - resistance, and thermal stability help ensure process accuracy, reduce pollution risks, and improve equipment reliability.

How is Silicon Nitride Ceramics Manufactured?

The manufacturing process of silicon nitride ceramics is complex and requires strict control of multiple processes. Take Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. as an example to illustrate the general production process.

Raw Material Processing

The production of silicon nitride ceramics starts with high - purity silicon nitride powder as the raw material. Sometimes, a small amount of sintering aids such as MgO, Al2O3, or Y2O3 are added. These additives can promote sintering and improve the properties of the final product. For example, MgO can reduce the sintering temperature and improve the density of silicon nitride ceramics. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. strictly selects high - quality raw materials to ensure the quality of the products from the source. Their quality inspection process for raw materials is very strict, which includes tests on the purity, particle size distribution, and chemical composition of the powder.

Molding Process

Dry Pressing

In the dry - pressing process, the mixed powder (silicon nitride powder and additives) is placed in a mold and pressed under a certain pressure. The pressure applied is usually in the range of 10 - 50MPa. For example, when manufacturing some simple - shaped silicon nitride ceramic parts like small - sized blocks, dry pressing can be an efficient method. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. has advanced dry - pressing equipment, which can accurately control the pressure and ensure the uniformity of the pressed parts.

Cold Isostatic Pressing (CIP)

Cold isostatic pressing is suitable for manufacturing parts with complex shapes or large sizes. The powder is first filled into an elastic mold, and then the mold is placed in a liquid medium. Uniform pressure is applied from all directions, usually in the range of 100 - 300MPa. This allows the powder to be evenly compacted. For instance, when making large - diameter silicon nitride ceramic tubes, CIP can ensure that the density of the tube wall is uniform. The company's CIP equipment can handle different sizes and shapes of molds, meeting the diverse needs of customers.

Injection Molding

Injection molding is used to produce complex - shaped and high - precision silicon nitride ceramic components. A certain amount of binder is added to the powder to make it have good fluidity. The mixture is then injected into a mold cavity under high pressure through an injection machine. The injection pressure can reach 50 - 200MPa. This method is often used for manufacturing parts with fine internal structures, such as some micro - mechanical components. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. has a professional injection - molding production line, which can precisely control the injection process and the quality of the binder addition.

Subsequent Processing

High - Temperature Sintering

After molding, the green body needs to be sintered at high temperatures. The sintering temperature of silicon nitride ceramics is usually around 1600 - 1800℃. During sintering, the atoms in the powder diffuse and bond with each other, increasing the density and strength of the ceramic. For example, in the case of pressureless sintering, the heating rate, holding time, and sintering atmosphere (such as a nitrogen - rich atmosphere) all affect the sintering quality. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. is equipped with advanced high - temperature sintering furnaces, which can accurately control the sintering temperature, heating rate, and atmosphere, ensuring the high - quality sintering of silicon nitride ceramic products.

Machining

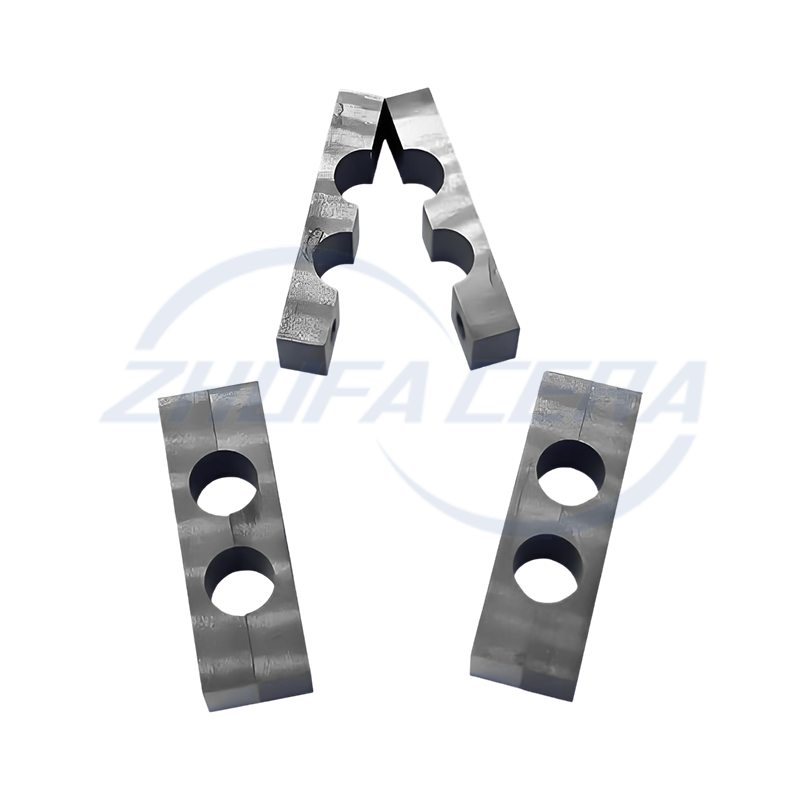

After sintering, the silicon nitride ceramic parts may need further machining to meet the dimensional accuracy and surface quality requirements. Common machining methods include grinding, drilling, and milling. For example, CNC engraving machines are used for precision engraving of patterns or holes on the ceramic surface, and surface grinders are used to improve the surface smoothness. The machining accuracy can reach the micron level. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. has a complete set of machining equipment, including CNC engraving machines, surface grinders, centerless grinders, etc., which can complete various machining tasks for silicon nitride ceramic products.

Where is Silicon Nitride Ceramics Applied?

1. Automotive Industry

Silicon nitride ceramics are widely used in various components of automobiles, such as engines, sensors, braking systems, and electronic control units. In engines, the high - temperature resistance of silicon nitride ceramics allows them to be used in parts like cylinder liners and piston rings. These parts can withstand high - temperature combustion environments, reducing wear and tear and improving engine efficiency. For sensors, the excellent insulation and high - temperature - resistant properties of silicon nitride ceramics ensure the stable operation of sensors in high - temperature and high - electromagnetic - interference automotive environments, improving the accuracy of data collection. In braking systems, silicon nitride ceramic - based brake pads have better wear - resistance and heat - dissipation performance. They can maintain stable braking performance during high - speed braking or continuous braking, enhancing the safety of the vehicle. In the development of new energy and smart cars, silicon nitride ceramics play an important role in promoting the performance improvement of key components, which is also in line with the high - quality product requirements of Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. for the automotive industry.

2. Photovoltaic Industry

In the photovoltaic industry, silicon nitride ceramics are applied in wafer cutting, coating, and high - temperature sintering processes. During wafer cutting, the high - hardness and wear - resistance of silicon nitride ceramics enable cutting tools made of them to have a long service life and high cutting precision, reducing the breakage rate of wafers and improving production efficiency. In the coating process, silicon nitride ceramics can be used as a coating material or a carrier for coating. Their excellent insulation and chemical stability can protect the surface of photovoltaic devices, prevent oxidation and corrosion, and improve the service life of devices. In high - temperature sintering, the high - temperature - resistant and heat - shock - resistant properties of silicon nitride ceramics allow the sintering furnace components made of them to work stably in high - temperature environments, ensuring the quality of sintering products. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. can provide high - quality silicon nitride ceramic products for the photovoltaic industry, meeting the needs of different process links.

3. Petrochemical Industry

In petrochemical equipment such as pumps, valves, seals, and reactors, silicon nitride ceramics are of great value. Pumps and valves made of silicon nitride ceramics can operate reliably in complex chemical media with strong corrosive and high - temperature characteristics. Their high wear - resistance and corrosion - resistance can effectively reduce the wear and corrosion of components in long - term use, reducing maintenance frequency and costs. For example, in the transportation of corrosive liquids such as sulfuric acid and hydrochloric acid, silicon nitride ceramic - lined pumps can ensure long - term stable operation. In reactors, silicon nitride ceramics can withstand high - temperature and high - pressure chemical reaction environments, providing a reliable guarantee for the normal progress of chemical reactions. The company's silicon nitride ceramic products with excellent performance can well meet the harsh requirements of the petrochemical industry.

4. Semiconductor Industry

Silicon nitride ceramics are extensively used in semiconductor equipment, including wafer handling, etching, deposition, and detection equipment. Their high purity ensures that they will not introduce impurities during the semiconductor manufacturing process, reducing the risk of product contamination. The insulation property makes them suitable for use in electronic components where insulation is required, such as in the isolation layers of integrated circuits. Their wear - resistance ensures that the components in contact with wafers can maintain long - term accuracy during repeated operations. In etching and deposition equipment, the thermal stability of silicon nitride ceramics allows them to work stably under high - temperature and high - energy - density conditions, ensuring the accuracy and stability of the process. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. can provide high - precision silicon nitride ceramic components for the semiconductor industry, helping semiconductor manufacturers improve production quality and efficiency.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어