Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

1. What Constitutes the Core Manufacturing Process of Yttrium-Stabilized Zirconia Ceramics?

The manufacturing of Yttrium stable zirconia ceramics relies on a precise, multi-step workflow that transforms raw powders into high-performance components, with each stage critical to final material properties.

It starts with raw material preparation, where zirconium dioxide (ZrO₂) is doped with 3–8% yttrium oxide (Y₂O₃) to stabilize its crystal structure and enhance mechanical performance . A typical high-performance formulation uses 94.7% ZrO₂ and 5.2% Y₂O₃ by weight, which delivers superior density and wear resistance compared to traditional alumina ceramics . For nano-sized YSZ powder—vital for applications like solid oxide fuel cell (SOFC) electrolytes—the process involves mixing zirconium oxychloride and yttrium chloride solutions, forming precipitates with a precipitating agent, filtering, drying at 100–120°C for 6 hours, and heat-treating at 550–950°C .

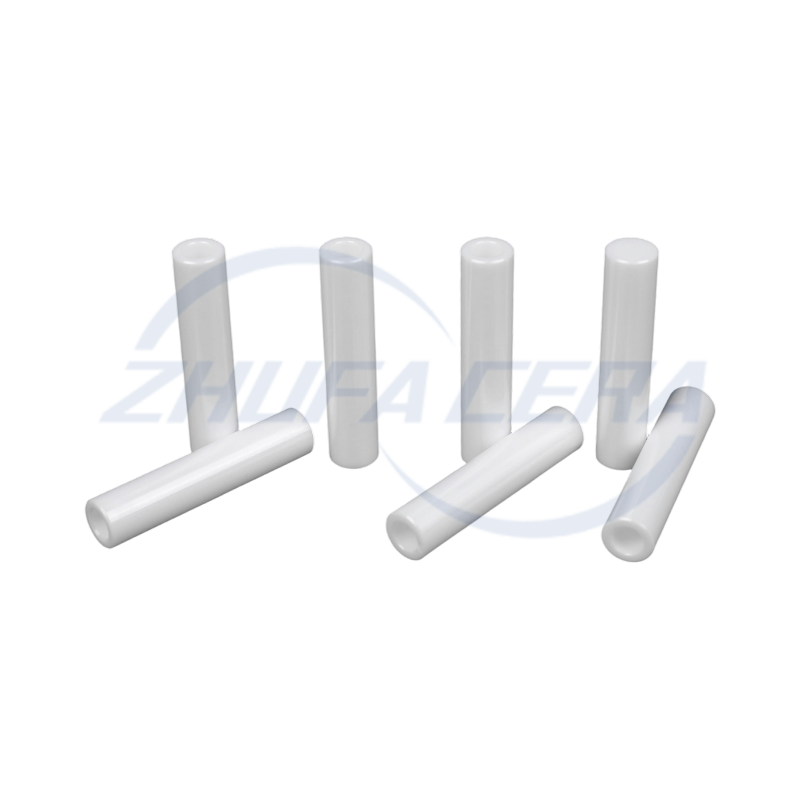

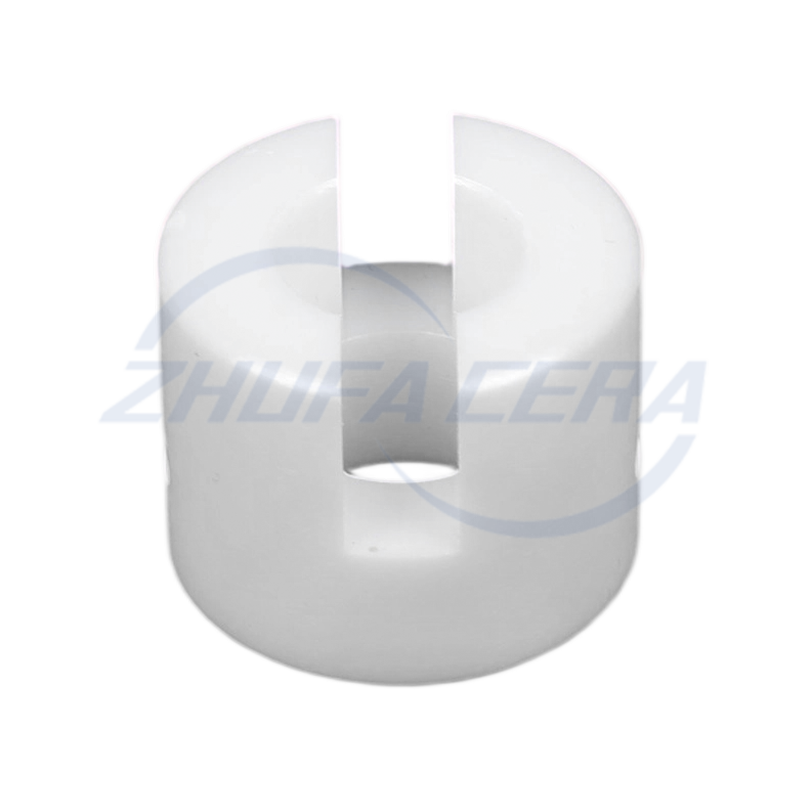

Next is shaping, where advanced techniques ensure dimensional precision. Facilities like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. utilize dry pressing, cold isostatic pressing, and injection molding to form green bodies, adapting to both simple and complex geometries . The shaping method is tailored to component requirements: cold isostatic pressing, for instance, is ideal for parts needing uniform density, while injection molding suits intricate structures like automotive sensors or electronic control unit components.

Sintering follows, typically at 1500–1600°C, to densify the green body into a high-strength, tough ceramic . High-temperature sintering furnaces are essential here to achieve the dense microstructure (grain size ≤ 0.5 μm) required for industrial durability . Finally, precision finishing with CNC engraving machines, surface grinders, and honing machines refines components to tight tolerances—critical for applications like semiconductor wafer handling tools or petrochemical valves . Zhejiang Zhufa’s 30,000㎡ manufacturing base integrates all these core processes, enabling end-to-end production from powder to finished part .

2. How to Ensure Consistent Performance in YSZ Ceramic Production?

Consistent performance of Yttrium-Stabilized Zirconia ceramics depends on rigorous control of material composition, process parameters, and quality inspection—factors that directly impact properties like wear resistance, thermal stability, and corrosion resistance.

Material validation is foundational. High-purity ZrO₂ (≥ 99.5%) is verified via X-ray fluorescence (XRF) analysis to meet standards like ISO 13356:2023, ensuring minimal impurities that could compromise performance . The yttrium doping ratio is also strictly controlled: too little Y₂O₃ fails to stabilize the crystal structure, while excess reduces mechanical strength. Zhejiang Zhufa emphasizes material traceability and statistical process control here, aligning with its technology-driven quality philosophy .

Process parameter optimization is equally critical. Sintering temperature and duration must be calibrated to avoid defects: overly rapid heating causes cracking, while insufficient sintering leaves porous structures. For high-temperature applications (e.g., SOFC electrolytes), sintering at 1500–1600°C ensures the ionic conductivity (critical at 600–1000°C) and thermal stability needed for long-term use .

Quality inspection penetrate the workflow. Non-destructive testing detects internal defects, while microstructure inspection via scanning electron microscopy (SEM) confirms grain size compliance (≤ 0.5 μm per ASTM F 2079-21) . Thermal resistance testing—subjecting components to cycles at 800°C with ≤ 1% property degradation—validates suitability for harsh environments like petrochemical reactors or automotive engines . These steps, enforced by facilities like Zhejiang Zhufa, ensure each YSZ part meets the performance demands of industries from new energy vehicles to semiconductors .

3. What Shaping and Finishing Techniques Suit Complex Yttrium-Stabilized Zirconia Ceramic Components?

Complex YSZ components—such as automotive braking system parts, semiconductor etching tools, and petrochemical valves—require shaping and finishing methods that balance intricate geometry with tight tolerances and material integrity.

Advanced shaping methods are key to replicating complex designs. Cold isostatic pressing applies uniform pressure to powder in flexible molds, ideal for curved or hollow parts like fuel cell separators, ensuring consistent density across the component . Injection molding, used for small, detailed parts (e.g., sensor housings), mixes YSZ powder with binders to fill precise molds, with subsequent debinding to remove organics before sintering . Zhejiang Zhufa leverages both techniques in its in-house manufacturing, supporting low-volume prototyping and large-scale production of complex parts .

Precision finishing is essential for functional compatibility. CNC engraving machines create custom features (e.g., threaded holes in valve components) with micron-level accuracy, while centerless grinders ensure consistent outer diameters for rotating parts like bearings . Honing and pin grinding refine internal surfaces—critical for sealing in pumps or fluid flow in chemical reactors—reducing leakage risks and improving wear resistance .

These techniques address the unique challenges of complex YSZ parts: for example, custom-shaped valve components in petrochemical plants, fabricated via isostatic pressing and CNC machining, prevent misalignment and thermal cracking in aggressive chemical environments . By integrating these processes, manufacturers like Zhejiang Zhufa deliver non-standard YSZ components that meet cross-industry needs for precision and durability .

4. Which Industrial Applications Demand Custom YSZ Ceramic Solutions, and Why?

Custom YSZ ceramic solutions are indispensable in industries where off-the-shelf parts fail to meet unique performance, geometry, or environmental requirements—leveraging YSZ’s wear resistance, high-temperature stability, and chemical inertness.

Automotive and New Energy relies on custom YSZ parts for durability and efficiency. Engines, braking systems, and SOFCs use components shaped to fit specific assemblies: custom YSZ gears and engine parts enhance longevity via high toughness, while fuel cell electrolytes (tailored via nano-powder processing) deliver the ionic conductivity needed for energy conversion . Zhejiang Zhufa supports this sector with custom prototypes and large-scale production, aligning with the demands of smart and new energy vehicles .

Petrochemical Industry requires custom YSZ valves, seals, and pump parts. These components must withstand corrosive acids, high temperatures, and abrasive fluids—custom shaping (e.g., precision-machined seal faces) ensures a tight fit that prevents leakage, while YSZ’s chemical stability reduces maintenance costs . Compliance with standards like ISO 13356:2023, enforced by manufacturers like Zhejiang Zhufa, guarantees reliability in harsh chemical environments .

Semiconductor and Photovoltaics depend on high-purity, custom YSZ tools. Wafer handling components (e.g., end effectors) are machined to ultra-tight tolerances to avoid contamination, while photovoltaic wafer cutting parts leverage YSZ’s wear resistance to extend equipment life . Direct engineering support, a service offered by Zhejiang Zhufa, helps optimize designs for these precision-critical applications .

In each case, custom YSZ solutions resolve industry-specific pain points—from thermal degradation in automotive systems to corrosion in petrochemical plants—with manufacturers like Zhejiang Zhufa bridging material capabilities and application needs .

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어