Alumina Ceramics Manufacturers

-

Read More

Alumina Ceramic Valve Sleeve

Alumina Ceramic Valve Sleeve is a precision industrial component designed for high wear, strong corrosion and high temperature conditions. Its core advantage comes from the properties of 95%-99.7% pure alumina ceramic materials. Compared with traditional metal valve sleeves, its Mohs hardness is as high as 9 (second only to diamond), and its wear resistance is more than 20 times that of stainless steel. It can effectively resist long-term erosion by slurry, ash and other particle-containing media. In terms of chemical stability, the valve sleeve can withstand corrosion from most acid and alkali solutions (such as 32% sodium hydroxide and 95% sulfuric acid), while metal valve sleeves are prone to electrochemical corrosion in such environments. Its maximum operating temperature can reach 1760℃ (99.7% purity), which far exceeds the temperature resistance limit of metal materials. It is particularly suitable for high-temperature scenes such as oil drilling and chemical reactors. In addition, the low friction coefficient (surface roughness Ra≤0.4μm after precision grinding) and zero leakage sealing performance of alumina ceramics significantly improve the opening and closing efficiency and long-term reliability of the valve, and are widely used in key equipment such as ball valves, check valves, and mud valves.

-

Read More

Alumina Ceramic Crucible

Alumina Ceramic Crucible is a professional laboratory and industrial container made of high-purity alumina ceramic. Its main characteristics include excellent high temperature resistance (can withstand temperatures up to 1700°C), excellent chemical inertness (can resist corrosion from acids, alkalis and molten metals), and excellent thermal stability and mechanical strength (avoid cracking during rapid thermal cycles). In addition, it has a low thermal expansion coefficient and excellent insulation properties to ensure dimensional stability and electrical isolation in high temperature environments. Its role is to provide a safe and reliable container for high-temperature melting, chemical reactions and sample processing, effectively preventing material contamination and ensuring the accuracy of experimental results, especially for demanding chemical and metallurgical processes. Alumina Ceramic Crucible has a wide range of uses, covering multiple professional fields, such as in materials science for sintering and melting of metal or ceramic powders, in the chemical industry as a catalyst carrier or high-temperature reaction vessel, and in analytical laboratories for ash determination, sample firing or elemental analysis. Its high purity and low contamination characteristics make it an ideal choice in semiconductor manufacturing, environmental testing and scientific research and development, which can significantly improve processing efficiency and experimental repeatability.

-

Read More

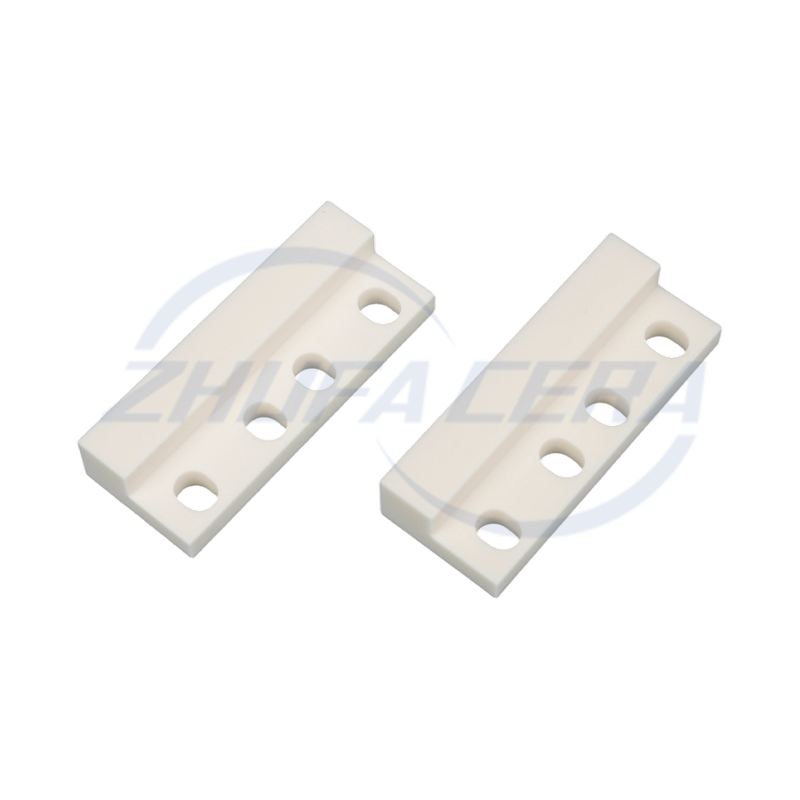

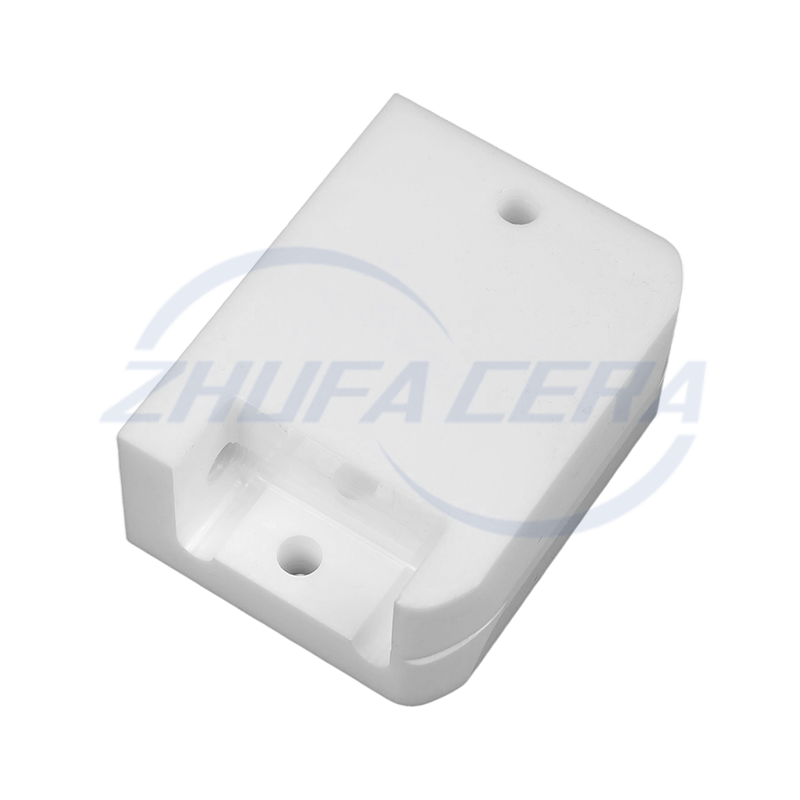

Fixed Bracket Alumina Ceramic

Fixed Bracket Alumina Ceramic is a high-performance support element designed for harsh industrial environments. Compared with traditional metal or plastic brackets, its core advantage is that it is made of high-purity alumina ceramic (Al₂O₃≥95%), which has excellent mechanical strength, extreme corrosion resistance and excellent electrical insulation properties. The product can maintain structural stability at a high temperature of 1600°C, and withstand the erosion of strong acids, strong alkalis and organic solvents, completely avoiding the problems of easy rust of metal brackets and easy aging and deformation of plastic brackets. At the same time, its hardness is second only to diamond, and its wear resistance is more than 5 times that of special steel, which greatly extends the equipment maintenance cycle. Alumina ceramic fixed brackets are widely used in semiconductor manufacturing, chemical reactors, high-temperature kilns, medical equipment and high-precision measuring instruments, providing long-lasting and reliable positioning and support for key components, significantly improving the safety and service life of the system.

-

Read More

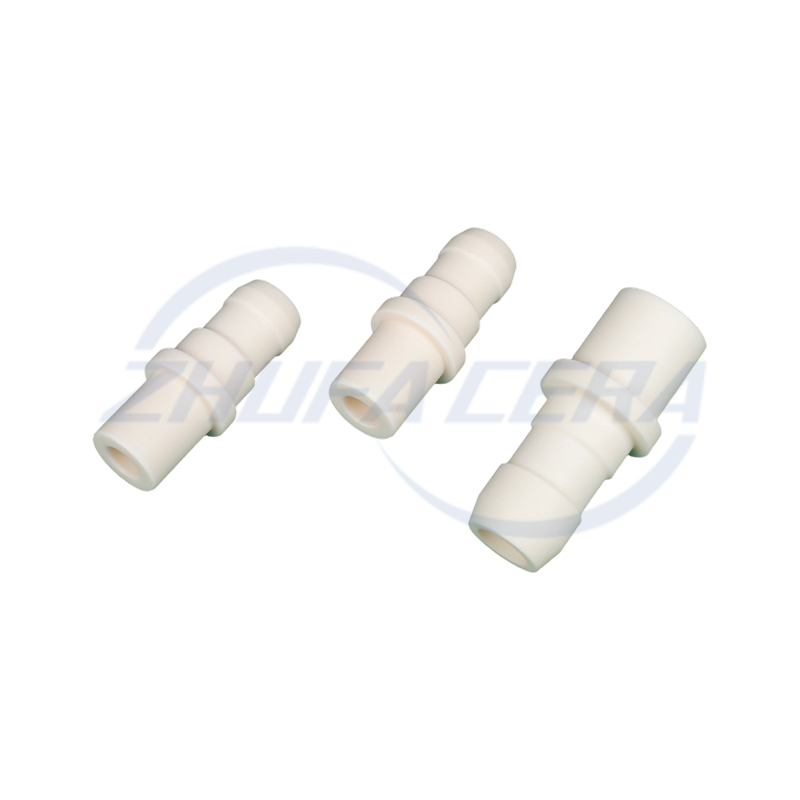

Alumina Ceramic Tube Fitting

Alumina Ceramic Tube Fitting is a pipe fitting made of high-purity alumina ceramic material. Its core properties include excellent hardness, outstanding wear resistance and corrosion resistance. The product can maintain structural stability in extreme temperatures (such as up to 1600°C) and high-pressure environments, and has excellent electrical insulation properties to prevent the risk of current leakage. Its role is to provide a reliable sealed connection to ensure the efficient and safe transmission of fluids or gases in the pipeline system, effectively reduce leakage accidents, and improve the reliability and life of the overall system. In addition, the design of Alumina Ceramic Tube Fitting optimizes fluid dynamics and minimizes flow resistance, thereby supporting high-precision control applications. This pipe fitting has a wide range of uses in multiple industrial fields, especially in semiconductor manufacturing, chemical processing, medical equipment and high-temperature furnace systems. Its chemical inertness and biocompatibility make it an ideal choice for handling corrosive media, high-purity liquids or sterile environments, ensuring contamination-free operation. The long-term durability and low maintenance requirements of Alumina Ceramic Tube Fitting significantly reduce operating costs, while its lightweight design facilitates installation and integration, providing efficient solutions for complex industrial processes.

-

Read More

Alumina Ceramic Structural Components

Alumina Ceramic Structural Components is a structural component made of high-purity alumina ceramic material. Its main characteristics include excellent mechanical strength, high hardness and outstanding wear resistance, ensuring structural integrity under extreme loads; it has excellent high temperature resistance, and the operating temperature can reach above 1600°C. At the same time, it shows strong chemical stability and inertness, effectively resisting the corrosion of acids, alkalis and corrosive media; in addition, the component has high electrical insulation and low thermal expansion coefficient, which can provide reliable isolation and stability in electrical and thermal management applications. Its role is to provide critical structural support and protection for industrial systems, such as reducing the risk of failure in high-pressure or high-wear environments, and ensuring safe operation in sensitive equipment through its biocompatibility and non-magnetic design. This structural part is widely used in multiple industrial fields. For example, in the electronics and semiconductor industries, it is used as an insulator or substrate to ensure electrical isolation and thermal management of circuit elements. In mechanical engineering, it is used to manufacture bearings, seals, and pump and valve components to improve the wear resistance and service life of the equipment. In the chemical and energy fields, it serves as reactor linings or pipeline components, withstanding corrosive fluids and high-temperature environments. In addition, it is used as an implant or surgical tool component in medical devices, thanks to its biological inertness. It is also used for lightweight and high-strength structures in the aerospace and automotive industries to meet the reliability and durability requirements under harsh working conditions.

-

Read More

Alumina Ceramic Metal Head Pump

The Alumina Ceramic Metal Head Pump is made of high-purity alumina ceramic material, and its metal head component enhances the rigidity and mechanical stability of the overall structure. The key features of the pump include excellent wear resistance, corrosion resistance and chemical inertness, and can maintain stable performance under high temperature and high pressure environments; in addition, its ceramic surface is highly smooth, which reduces fluid resistance and improves sealing efficiency. As a conveying device, the core function of the pump is to efficiently handle corrosive or abrasive media, such as strong acids, strong alkalis or liquids containing solid particles, to ensure the continuity and safety of the fluid transmission process. The Alumina Ceramic Metal Head Pump is widely used in industries such as chemical, pharmaceutical, water treatment and mineral processing, and is particularly suitable for pumping slurries, wastewater or high-purity chemicals. Its design optimizes service life and maintenance requirements, such as extending the component replacement cycle under harsh conditions, thereby reducing operating costs; at the same time, the pump also plays a key role in fields with high cleanliness requirements such as semiconductor manufacturing or food processing, meeting strict hygiene and performance standards.

-

Read More

Metal-Clad Alumina Ceramic Pump

Metal-Clad Alumina Ceramic Pump is a composite fluid conveying equipment that combines a metal shell with an alumina ceramic lining, designed specifically for handling highly corrosive and highly abrasive media. Compared with traditional all-metal pumps or ordinary ceramic pumps, this product enhances mechanical strength through a metal outer shell structure, while utilizing the high hardness and chemical corrosion resistance of alumina ceramics to significantly extend service life. Its core advantage is that it simultaneously solves the industry pain points of metal pumps being prone to corrosion and ceramic pumps being prone to brittle cracking. Metal-Clad Alumina Ceramic Pump adopts a double-layer composite structure: the outer layer is a pressure-resistant metal shell (such as stainless steel or titanium alloy), and the inner layer is a high-purity alumina ceramic (Al₂O₃ content ≥ 95%) lining. The alumina ceramic lining is tightly combined with the metal shell through precision machining to form a seamless protective layer that can withstand strong acid and alkali environments with a pH value of 0-14, and resist erosion by solid particles with a particle size of ≤1mm. The equipment has an operating temperature range of -20℃ to 250℃ and a maximum working pressure of 2.5MPa. It is suitable for conveying media such as sulfuric acid, hydrochloric acid, sodium hydroxide solution and slurry. Its modular design supports rapid replacement of ceramic linings and reduces maintenance costs. The product is widely used in processes such as hydrometallurgy, flue gas desulfurization, electroplating wastewater treatment and semiconductor wafer cleaning, meeting the needs of continuous and stable operation under high corrosion and high wear conditions.

-

Read More

Alumina Ceramic Insulating Ring

Alumina Ceramic Insulating Ring is an annular insulating component made of high-purity alumina (Al₂O₃). Compared with insulating rings made of other materials (such as polymers or ordinary ceramics), the main difference and advantage of this product lies in its excellent comprehensive performance. Its core material properties give it extremely high electrical insulation strength, excellent mechanical hardness, excellent wear resistance, and excellent thermal shock resistance and high temperature stability (long-term use temperature can reach above 1600°C). This enables the alumina ceramic insulating ring to maintain stable insulation performance in extreme electrical and electronic environments with high temperature, high pressure, high frequency, strong corrosion or high reliability, effectively isolate current and protect sensitive components, and meet the application scenario requirements with strict requirements on the performance of insulating materials. Main features and parameters (typical values):Material composition: Al₂O₃ (92%, 95%, 99%, etc.)Insulation strength: >15 kV/mmVolume resistivity: >10^14 Ω·cm (room temperature)Dielectric constant: ~9-10 (1MHz)Coefficient of thermal expansion: ~7-8 x 10^-6 /KThermal conductivity: ~20-30 W/mKFlexural strength: >300 MPaVickers hardness: ~1500 HVMaximum operating temperature: >1500°C (long term)Main uses:Alumina ceramic insulation rings are widely used in fields requiring high-performance insulation and structural support:Power electronics: high-voltage insulators, power transmission insulation parts, circuit breakers, disconnectors, IGBT module insulation substrates/gaskets, semiconductor manufacturing equipment.Electronic components: vacuum tube (such as magnetron, klystron) insulation support, connector insulators, sensor insulation sleeves, thick film/thin film circuit substrates.High temperature industry: furnace observation window, thermocouple protection tube, high temperature heating element support and insulation, molten metal processing equipment parts.Vacuum technology: vacuum chamber feedthrough insulation, vacuum switch tube insulation ring, vacuum coating equipment parts.Laser and optics: laser gas discharge tube insulation ring, optical platform support insulation.Medical equipment: insulation components in some high-energy medical equipment (such as X-ray tubes).Aerospace and defense: high-frequency and high-voltage insulation parts in radar systems and communication equipment.

-

Read More

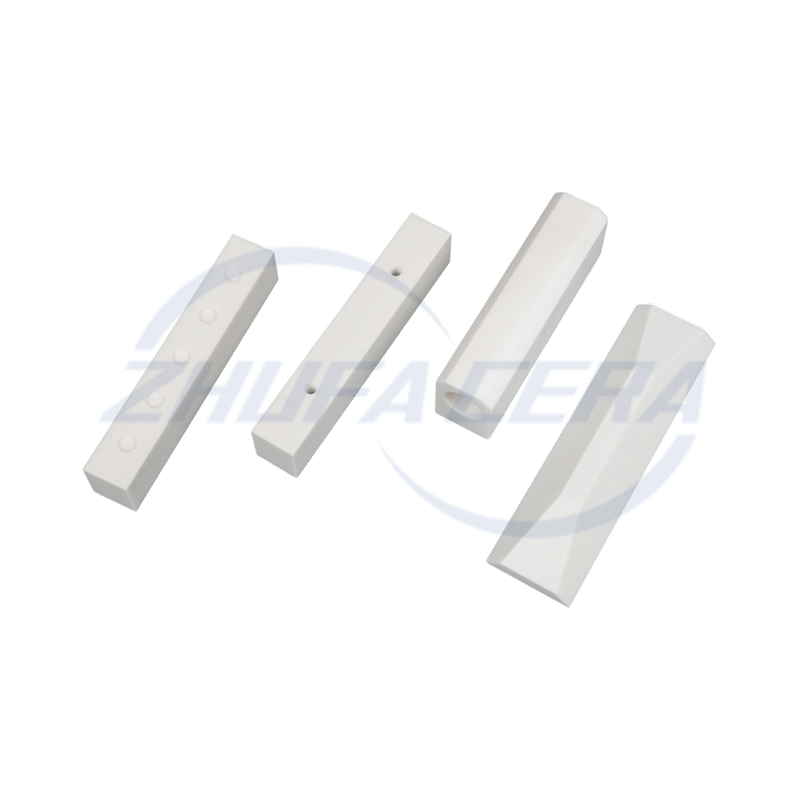

Alumina Ceramic Block

Alumina Ceramic Block is an advanced engineering ceramic material with high-purity α-alumina (Al₂O₃) as the main component, made by high-temperature sintering process. Compared with other ceramic materials, this product has achieved excellent mechanical strength, hardness and wear resistance by virtue of its precise control of alumina content (usually 92%-99.9%). The Mohs hardness can reach 9, which is significantly higher than most metals and traditional ceramics. It has outstanding thermal stability and can maintain stable performance in a high temperature environment of 1650℃. It also has extremely low thermal conductivity and excellent electrical insulation (dielectric strength>10 kV/mm). In strong acid, strong alkali and corrosive gas environments, Alumina Ceramic Block exhibits chemical corrosion resistance far exceeding that of metal materials. These characteristics make it an irreplaceable key material in harsh industrial scenarios, especially suitable for fields with extremely high requirements for wear life, high temperature tolerance and insulation reliability. Core application scenariosIndustrial wear-resistant components: Wear-resistant linings, nozzles, and sleeves, extending the life of equipment by more than 10 times; Semiconductor manufacturing: wafer polishing fixtures, vacuum chamber linings, to avoid metal contamination. Electronics and energy technology: High-voltage insulating substrates, radio frequency windows, arc nozzles; Fuel cell bipolar plates, electrolyzer sealing diaphragms. Biomedical field: Orthopedic joint prostheses, dental implant bases; Surgical guides, imaging equipment detector packaging. Special environmental equipment: High-temperature furnace temperature measuring sleeves, plasma etching components; Chemical valve sealing rings, nuclear reactor neutron absorbers. Alumina Ceramic Block provides high-reliability and long-life ceramic solutions for high-end industry and technology through the deep combination of material science and engineering design.

-

Read More

Threaded Alumina Ceramic Rod

Threaded Alumina Ceramic Rod is a functional ceramic component designed for harsh industrial environments. Different from ordinary ceramic rods, its core feature is the threaded structure with precision machining on the surface, which can be directly mechanically connected to metal or plastic parts, eliminating the need for additional bonding or nesting. This product is sintered with high-purity alumina (Al₂O₃) and has the inherent insulation, high temperature resistance and chemical inertness of ceramics. At the same time, by optimizing the thread geometry design, it ensures reliable connection strength in vibration, high temperature or corrosive media. This feature makes it more assembly efficient and structurally stable than non-threaded ceramic rods in scenarios such as semiconductor equipment, high-temperature sensor brackets and internal components of chemical reactors.

-

Read More

Alumina Ceramic Disc

Alumina Ceramic Disc is a ceramic component made of high-purity α-alumina (Al₂O₃ content 96%-99.8%) sintered at high temperature. Compared with metal, plastic or traditional ceramic discs, its differentiated characteristics include: Physical properties: Mohs hardness up to 9, density 3.8-3.9 g/cm³ (lower than metal), elastic modulus of about 350 GPa, providing high wear resistance and structural rigidity. Tolerance: Maximum operating temperature > 1600°C, low thermal expansion coefficient (7-8×10⁻⁶/K), maintaining dimensional stability in thermal shock environment; volume resistivity > 10¹⁴ Ω·cm, resistant to strong acid, strong alkali and organic solvent erosion. Functional characteristics: no ion release, no magnetism, specific purity level meets biocompatibility requirements.These properties make alumina ceramic discs suitable for corrosion, high temperature, high wear and insulation scenarios where metals or polymers are prone to failure, meeting the needs of precision engineering applications.

-

Read More

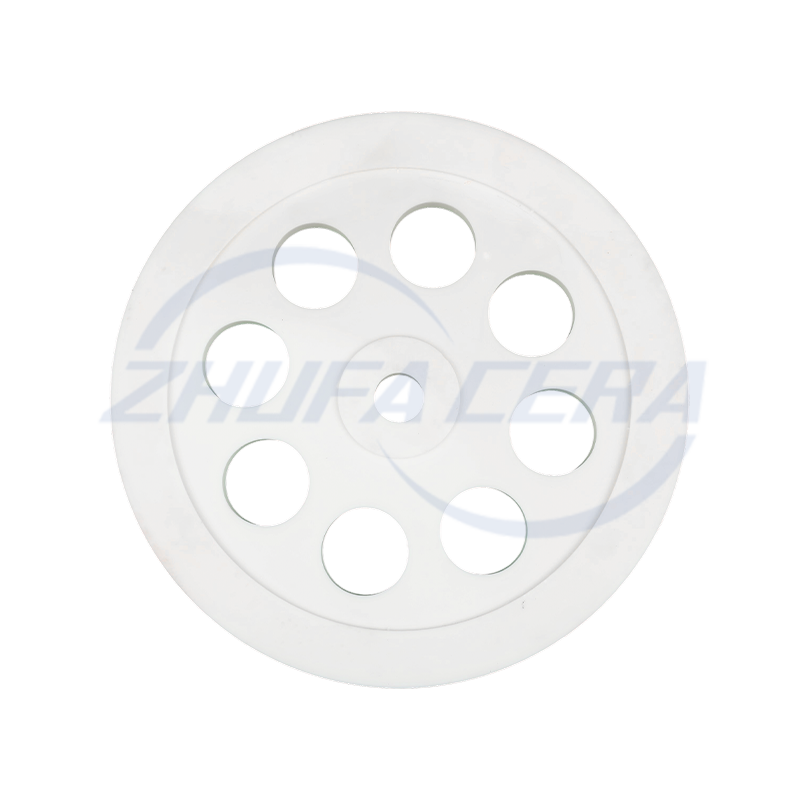

Alumina Ceramic Perforated Disc

Alumina Ceramic Perforated Disc is a precision porous ceramic component made of high-purity aluminum oxide (Al₂O₃). Its core advantage lies in its excellent physical and chemical stability. Compared with similar perforated components made of metal or polymer, this product has significant differences: its hardness can reach Mohs 9, and its wear resistance far exceeds that of stainless steel; it can withstand temperatures up to 1600°C and is suitable for extreme high temperature environments; it also has excellent acid and alkali corrosion resistance and electrical insulation, and can be exposed to strong corrosive media or high-frequency electric fields for a long time without failure. Alumina Ceramic Perforated Disc has low thermal expansion coefficient and zero outgassing characteristics, and is widely used in semiconductor, chemical and high-temperature filtration industries. It provides more lasting dimensional stability and process purity guarantee in the field, solving the pain points of traditional materials that are easy to deform, age or contaminate the medium. Main application areasIndustrial filtration and separation: high-temperature molten metal filtration, chemical catalyst carrier, and sterile filter plate in the pharmaceutical industry. Energy and environmental protection equipment: fuel cell gas diffusion layer, flue gas dust removal porous lining, MEMS sensor microfluidic chip. Electronics and semiconductors: wafer etching fixture, vacuum feedthrough insulation ring, plasma reactor distribution plate. High temperature processing equipment: sintering furnace support plate, heat treatment tooling bracket, burner flame diffuser.

Alumina Ceramics is a high-performance ceramic material made of alumina as the main raw material. According to the different alumina content, it can be divided into low-alumina ceramics (alumina content of 30% - 50%), medium-alumina ceramics (alumina content of 50% - 75%) and high-alumina ceramics (alumina content of more than 75%, of which 95 ceramics and 99 ceramics are common high-purity types). Different types of Alumina Ceramics have their own characteristics: low-alumina ceramics have low cost and moderate mechanical strength, which are suitable for scenes with low performance requirements; medium-alumina ceramics have certain improvements in strength, hardness and wear resistance, and have both cost-effectiveness and practicality; high-alumina ceramics show excellent performance, not only with high hardness (Mohs hardness can reach level 9, second only to diamond), but also with excellent high temperature resistance (can work stably in high temperature environments above 1600°C), good chemical stability (strong acid and alkali corrosion resistance) and excellent insulation performance, and Alumina Ceramics It has a wide range of uses. In the electronics industry, high-alumina ceramics are often used as integrated circuit substrates, electron tube sockets, etc., and their good insulation and thermal conductivity ensure the stable operation of electronic components; in the field of mechanical manufacturing, it can be used to make wear-resistant parts such as bearings and seals to extend the service life of mechanical equipment; in the chemical industry, due to its corrosion resistance, it is often used to make reactor linings, pipes, etc.; in addition, in the medical field, high-purity Alumina Ceramics can also be used to make implants such as artificial joints with good biocompatibility. In short, Alumina Ceramics plays an irreplaceable role in multiple industries with its diverse classification and excellent comprehensive performance. It is one of the important high-performance materials in modern industry.

-

Ceramic materials play a crucial role in modern industrial applications, from electronics to biomedical devices. Among the widely used advanced ceramics, ZTA Ceramics and ZrO₂ Ceramics stand out for their exceptional mechanical, thermal, and chemical properties. Understanding the differences between these two materia

READ MORE -

The Influence of Zirconia Content on the Performance of ZTA Ceramics Zirconia Toughened Alumina (ZTA) ceramics are widely used in industries where superior mechanical strength and thermal stability are critical. The combination of zirconia (ZrO2) and alumina (Al2O3) results in a material with enhanced toughness, making

READ MORE

-

Black silicon carbide ceramic ring is a high-performance engineered ceramic assembly made

See Details -

Zirconia Ceramic Rod is a high-performance ceramic material rod, mainly made of zirconium

See Details -

Blue zirconia ceramic sheets are precision components made of advanced zirconia ceramic

See Details -

This blue zirconia ceramic pin is made of advanced zirconia ceramic material, providing

See Details -

Zirconia Ceramic Gear is made of zirconium oxide ceramic material, which has excellent hig

See Details -

Zirconia Ceramic Guide Rail is a high-performance precision mechanical component made of z

See Details

Alumina Ceramics: Key Insights into Manufacturing, Performance, and Industrial Applications?

What Core Characteristics Make Alumina Ceramics a Go-To Material for Precision Industries?

Alumina ceramics, primarily composed of aluminum oxide, stand out as a cornerstone of advanced ceramic materials due to their exceptional inherent properties. These include high hardness (second only to diamond among common industrial materials), excellent electrical insulation, resistance to high temperatures (withstanding over 1,600°C in many cases), and strong corrosion resistance against most chemicals. For manufacturers focused on precision components, these traits are non-negotiable—and Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. amplifies these advantages through strict process control. As a source factory specializing in new ceramic materials, the company ensures each alumina ceramic part retains consistent performance, aligning with industrial demands for reliability in harsh operating environments.

How Does Modern Manufacturing Ensure High-Quality Alumina Ceramics?

The manufacturing of alumina ceramics is a precision-driven process, with each step directly impacting final product quality. The typical workflow includes raw material purification (to reduce impurities that weaken performance), forming (such as dry pressing, cold isostatic pressing, or injection molding for complex shapes), high-temperature sintering (to achieve dense, stable ceramic bodies), and precision finishing (for tight dimensional tolerances).

Zhejiang Zhufa supports this workflow with a 30,000㎡ state-of-the-art manufacturing base, equipped with core machinery like high-temperature sintering furnaces, CNC engraving machines, and centerless grinders. This end-to-end in-house production capability—from raw material processing to final inspection—allows the company to control every detail, whether for standard alumina parts or non-standard, small-batch prototypes. By adhering to technology-driven standards, it ensures the alumina ceramics meet the strict precision and performance requirements of industrial clients.

Which Industrial Sectors Rely Heavily on Alumina Ceramics, and Why?

Alumina ceramics’ versatility makes them indispensable across multiple high-demand industries, with applications tailored to their unique strengths:

Automotive & New Energy: Used in sensors, braking systems, and electronic control units, their wear resistance and insulation improve vehicle safety and durability—key for new energy and smart car development.

Photovoltaics: Applied in wafer cutting and high-temperature sintering processes, their heat resistance and wear resistance boost production efficiency and extend equipment life.

Petrochemicals: Integrated into pumps, valves, and seals, their corrosion resistance ensures reliable operation in complex chemical environments, reducing maintenance costs.

Semiconductors: Utilized in wafer handling and etching equipment, their high purity and thermal stability minimize pollution risks and maintain process accuracy.

Zhejiang Zhufa leverages its cross-industry expertise to tailor alumina ceramic solutions for these sectors, supporting both small-batch trials and large-scale delivery to meet diverse client needs.

What Advantages Do Customized Alumina Ceramic Services Offer, and How Does Zhejiang Zhufa Deliver Them?

Industrial clients often require alumina ceramics tailored to unique shapes, sizes, or performance specs—standard off-the-shelf products rarely suffice. Customized services address this by aligning materials and design with specific application goals, such as optimizing for extreme temperatures or tight dimensional precision.

Zhejiang Zhufa excels in this area by offering fully in-house customization, direct engineering support, and flexible production (from small-batch proofing to mass manufacturing). Its customer-centric service system includes end-to-end support: from collaborating on design optimization to shorten development cycles, to ensuring consistent lead times. This approach not only meets clients’ performance and efficiency needs but also helps enhance their market competitiveness.

-

Quick Links

Home Products About Us Services Technology News Contact Us -

Products

Ceramic Structural Parts Zirconia Ceramics Alumina Ceramics ZTA Ceramics Silicon Nitride Ceramics Silicon Carbide Ceramics Ceramic Injection Molded Parts -

About Us

Factory Tour Honor FAQ -

Contact info

+86-188 8878 5188zf@zfcera.comNo. 1, Xinggong Road, Anchang Industrial Park, Keqiao District, Shaoxing City, Zhejiang Province, China -

Qrcode

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어