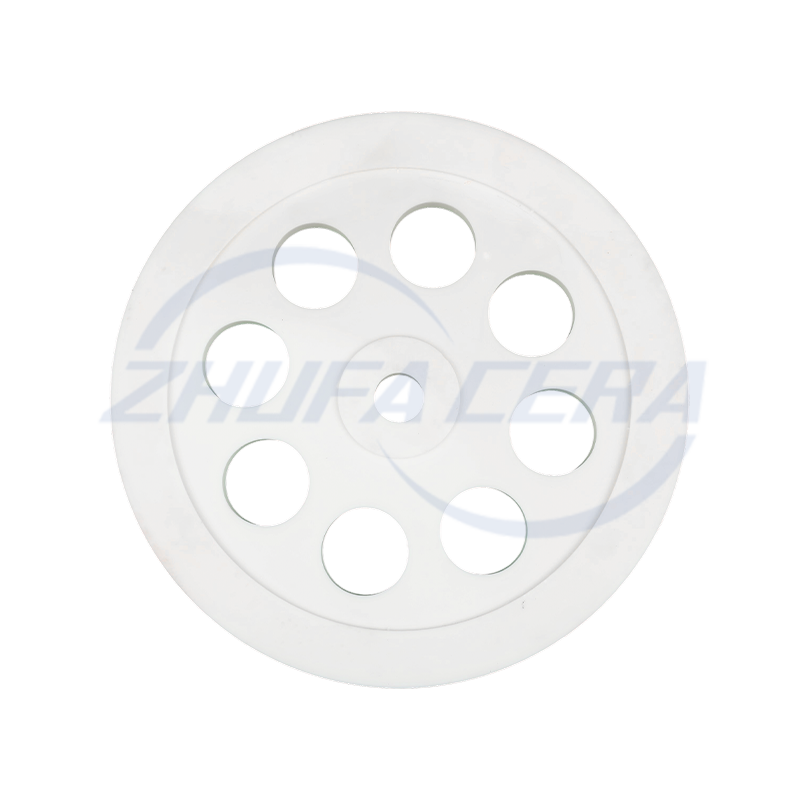

Alumina Ceramic Perforated Disc is a precision porous ceramic component made of high-purity aluminum oxide (Al₂O₃). Its core advantage lies in its excellent physical and chemical stability. Compared with similar perforated components made of metal or polymer, this product has significant differences: its hardness can reach Mohs 9, and its wear resistance far exceeds that of stainless steel; it can withstand temperatures up to 1600°C and is suitable for extreme high temperature environments; it also has excellent acid and alkali corrosion resistance and electrical insulation, and can be exposed to strong corrosive media or high-frequency electric fields for a long time without failure. Alumina Ceramic Perforated Disc has low thermal expansion coefficient and zero outgassing characteristics, and is widely used in semiconductor, chemical and high-temperature filtration industries. It provides more lasting dimensional stability and process purity guarantee in the field, solving the pain points of traditional materials that are easy to deform, age or contaminate the medium.

Main application areas

Industrial filtration and separation: high-temperature molten metal filtration, chemical catalyst carrier, and sterile filter plate in the pharmaceutical industry.

Energy and environmental protection equipment: fuel cell gas diffusion layer, flue gas dust removal porous lining, MEMS sensor microfluidic chip.

Electronics and semiconductors: wafer etching fixture, vacuum feedthrough insulation ring, plasma reactor distribution plate.

High temperature processing equipment: sintering furnace support plate, heat treatment tooling bracket, burner flame diffuser.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어