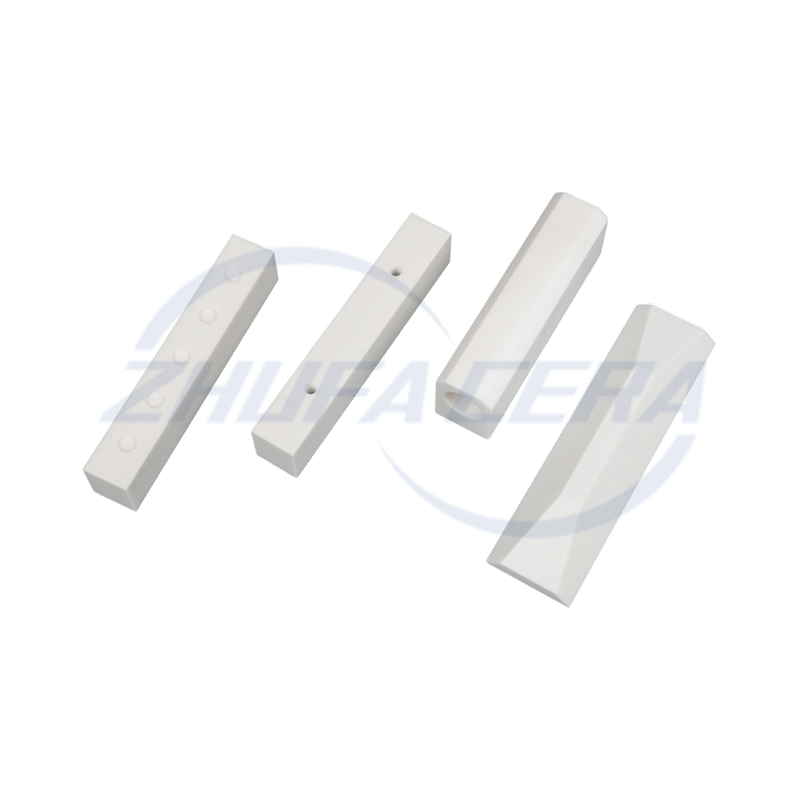

Alumina Ceramic Structural Components is a structural component made of high-purity alumina ceramic material. Its main characteristics include excellent mechanical strength, high hardness and outstanding wear resistance, ensuring structural integrity under extreme loads; it has excellent high temperature resistance, and the operating temperature can reach above 1600°C. At the same time, it shows strong chemical stability and inertness, effectively resisting the corrosion of acids, alkalis and corrosive media; in addition, the component has high electrical insulation and low thermal expansion coefficient, which can provide reliable isolation and stability in electrical and thermal management applications. Its role is to provide critical structural support and protection for industrial systems, such as reducing the risk of failure in high-pressure or high-wear environments, and ensuring safe operation in sensitive equipment through its biocompatibility and non-magnetic design.

This structural part is widely used in multiple industrial fields. For example, in the electronics and semiconductor industries, it is used as an insulator or substrate to ensure electrical isolation and thermal management of circuit elements. In mechanical engineering, it is used to manufacture bearings, seals, and pump and valve components to improve the wear resistance and service life of the equipment. In the chemical and energy fields, it serves as reactor linings or pipeline components, withstanding corrosive fluids and high-temperature environments. In addition, it is used as an implant or surgical tool component in medical devices, thanks to its biological inertness. It is also used for lightweight and high-strength structures in the aerospace and automotive industries to meet the reliability and durability requirements under harsh working conditions.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어