Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

Mastering Ceramic Ring Manufacturing: Practical Insights into New Ceramic Materials and Processes

How to Select the Right New Ceramic Material for Industrial Ceramic Rings?

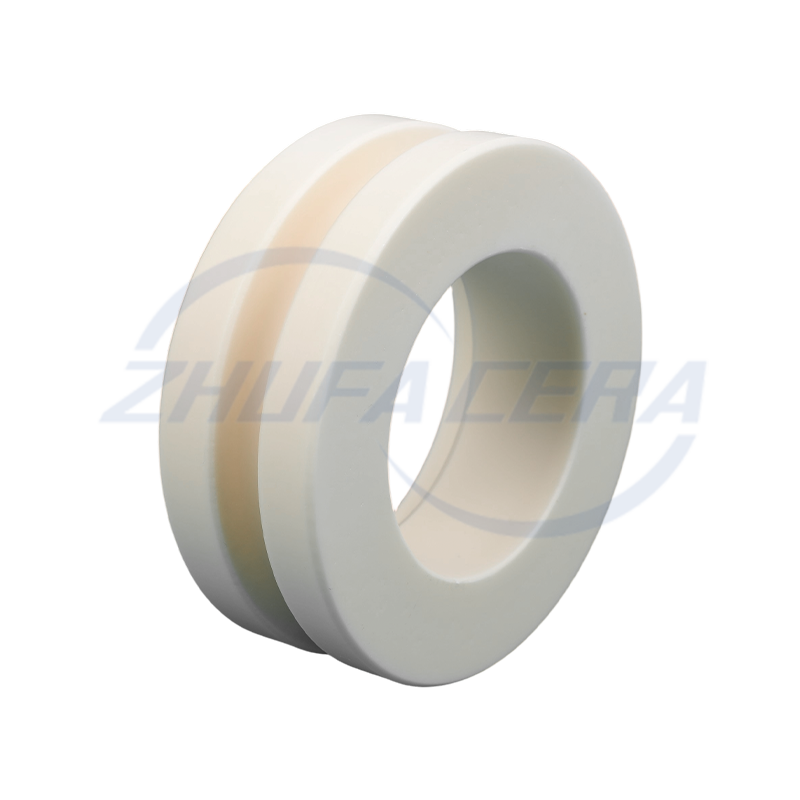

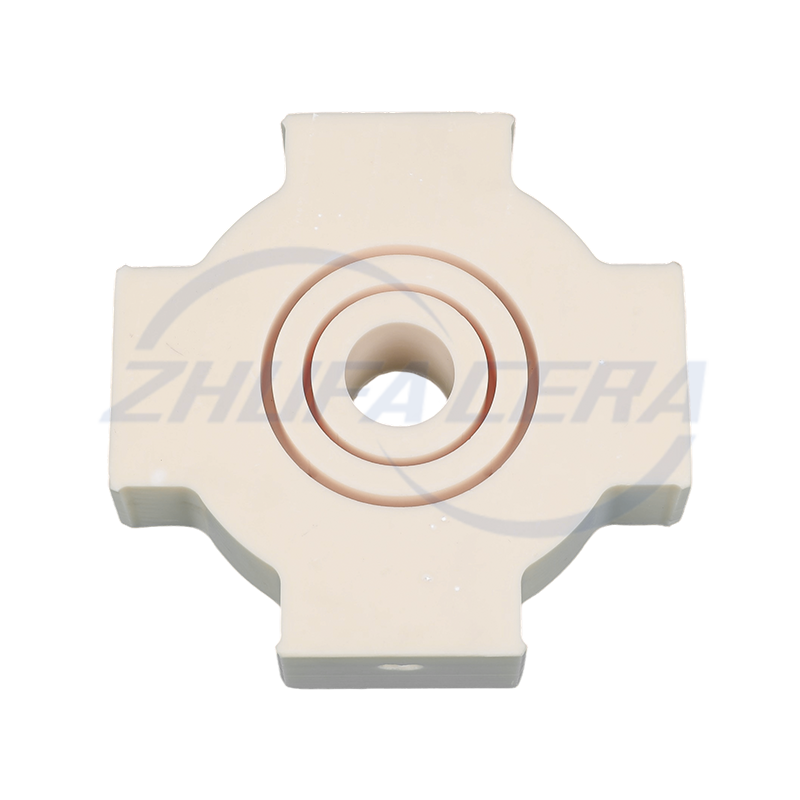

The functional reliability of ceramic rings starts with material selection, as different new ceramic materials are engineered to address distinct industrial challenges. Alumina ceramics, boasting Mohs hardness up to 9 and excellent acid resistance (resistant to most inorganic acids except hydrofluoric acid), are a cost-effective choice for general-purpose rings like filtration or basic structural components . Zirconia ceramics stand out for their superior toughness and thermal shock resistance, making them ideal for high-stress scenarios such as mechanical seals or precision bearing rings . For extreme environments involving high temperatures (up to 1800℃) and corrosion, silicon carbide and silicon nitride ceramics deliver unmatched performance, suitable for chemical reactor packing or high-temperature furnace components .

Source factories like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. offer tailored material solutions across zirconium oxide, aluminum oxide, silicon nitride, and silicon carbide, ensuring ceramic rings align with specific industrial requirements—whether for wear resistance, thermal management, or corrosion protection .

What Are the Critical Forming and Sintering Techniques for Ceramic Rings?

Forming and sintering directly determine the dimensional stability and mechanical strength of ceramic rings, with process selection depending on ring size and complexity. Extrusion molding is widely used for standard-sized rings (e.g., Raschig rings), where mixed ceramic powders are pressed through custom dies to achieve uniform annular shapes . For precision structural rings with complex geometries, injection molding offers better shape fidelity, though it requires precise control of slurry viscosity to avoid defects .

Sintering is the make-or-break stage: temperatures typically range from 1000℃ to 1400℃, but parameters must be calibrated to the material—for example, zirconia requires slower heating rates to prevent phase cracking . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. emphasizes process detail control, from mold design to sintering curve optimization, minimizing shrinkage-related deformations that often plague ceramic ring production .

How to Achieve Micron-Level Precision in Ceramic Ring Machining?

Ceramic rings’ inherent hardness and brittleness make precision machining a major challenge, especially for applications requiring tight tolerances (e.g., bearing rings with ≤0.001mm roundness). CNC grinding with diamond tools is the industry standard, as diamond’s extreme hardness withstands abrasion from ceramic materials . Advanced ceramic precision engraving machine further enhance accuracy with ±0.003mm tolerance control and intelligent stress compensation, which adjusts cutting parameters in real time to prevent chipping .

For post-sintering refinement, lapping and polishing techniques can achieve surface roughness as low as Ra≤0.01μm, critical for sealing or rotating rings . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. supports non-standard processing and small-batch proofing, leveraging such precision machining capabilities to meet industrial customers’ strict requirements for dimensional accuracy and surface quality .

What Quality Inspection Methods Ensure Ceramic Ring Reliability?

Comprehensive quality inspection covers both dimensional precision and material performance to avoid in-field failures. Dimensional testing uses coordinate measuring machines (CMM) with 0.7μm accuracy to verify roundness, cylindricity, and tolerance—essential for rings used in rotating equipment . Surface inspection employs profilometers to detect micro-scratches or unevenness, which can compromise sealing or fluid flow .

Performance testing is application-specific: acid resistance tests for chemical industry rings, thermal shock tests for high-temperature components, and hardness measurements (via Mohs scale or Vickers hardness testing) for wear-resistant parts . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. adheres to strict quality control from raw material incoming checks to finished product testing, ensuring each ceramic ring meets performance and reliability standards .

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어