Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

How to Master Ceramic Sheet Manufacturing: Key Techniques and Practical Solutions for New Ceramic Materials

What Are the Core Material Selection Criteria for High-Performance Ceramic Sheets?

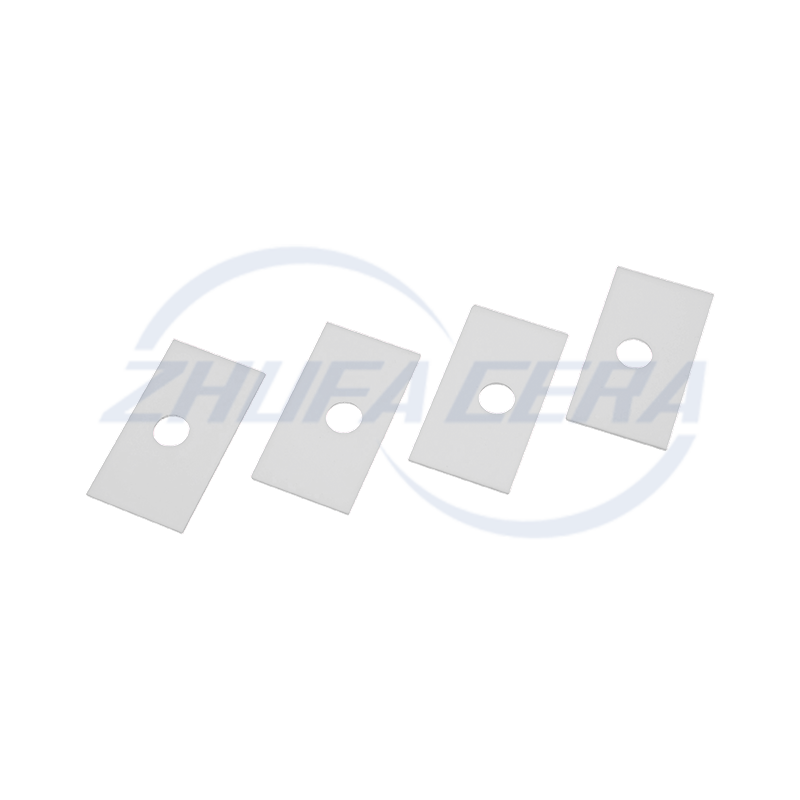

The performance of ceramic sheets is fundamentally determined by raw material selection, as different new ceramic materials exhibit distinct characteristics tailored to specific industrial needs. Alumina ceramics, with high hardness (around 2000HV) and excellent insulation, are ideal for wear-resistant and electrical insulation sheets . Zirconia ceramics stand out for their toughness and biocompatibility, making them suitable for precision structural sheets in medical and mechanical fields . For thermal management scenarios, aluminum nitride ceramics deliver superior thermal conductivity, while silicon carbide and silicon nitride excel in high-temperature and corrosion-resistant environments .

Source factories like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. prioritize matching material properties to customer demands, offering customized solutions across zirconium oxide, aluminum oxide, aluminum nitride, silicon nitride, and silicon carbide. This material diversity ensures ceramic sheets meet performance requirements for different industrial applications, from semiconductor equipment components to industrial structural parts .

How to Control the Forming and Sintering Processes for Uniform Ceramic Sheets?

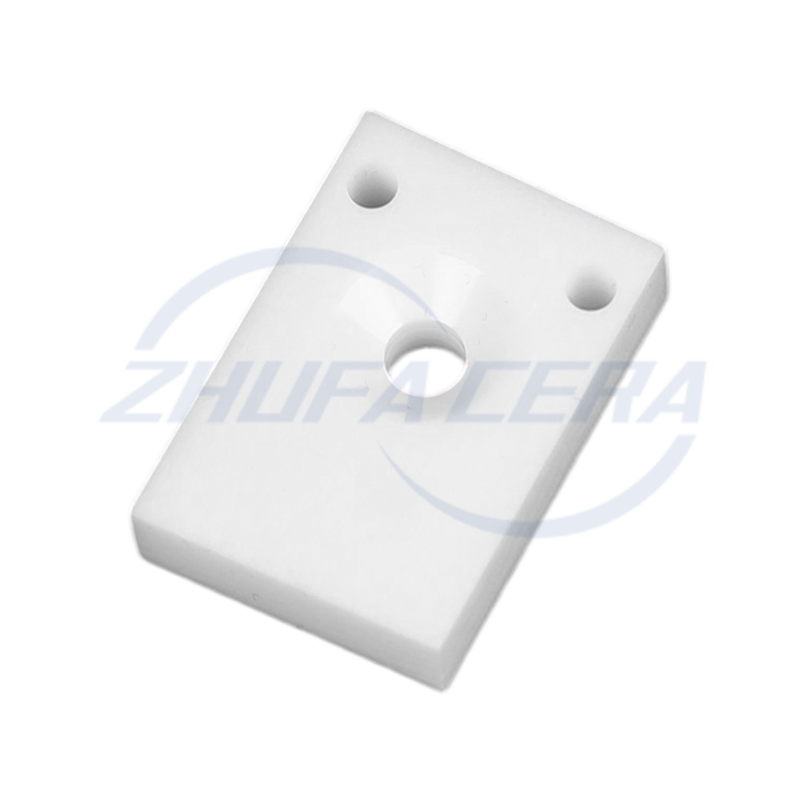

Forming and sintering are critical stages that directly affect the density, flatness, and structural stability of ceramic sheets. For simple-shaped sheets, dry pressing is widely used for its efficiency and cost-effectiveness, while complex-structured sheets require injection molding or hot die-casting to ensure shape accuracy . The key challenge lies in sintering: ceramic materials typically shrink by 15%-25% during this process, and uneven shrinkage leads to warping or cracking .

To address this, manufacturers adopt precise process control: solid-phase sintering is preferred for single-component sheets to ensure uniform densification, while liquid-phase sintering aids in densification of multi-component systems . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. emphasizes process details from equipment configuration to parameter adjustment, using technology-driven control to minimize sintering deformation, which is essential for maintaining the dimensional precision of ceramic sheets .

What Machining Techniques Ensure Micron-Level Precision for Ceramic Sheets?

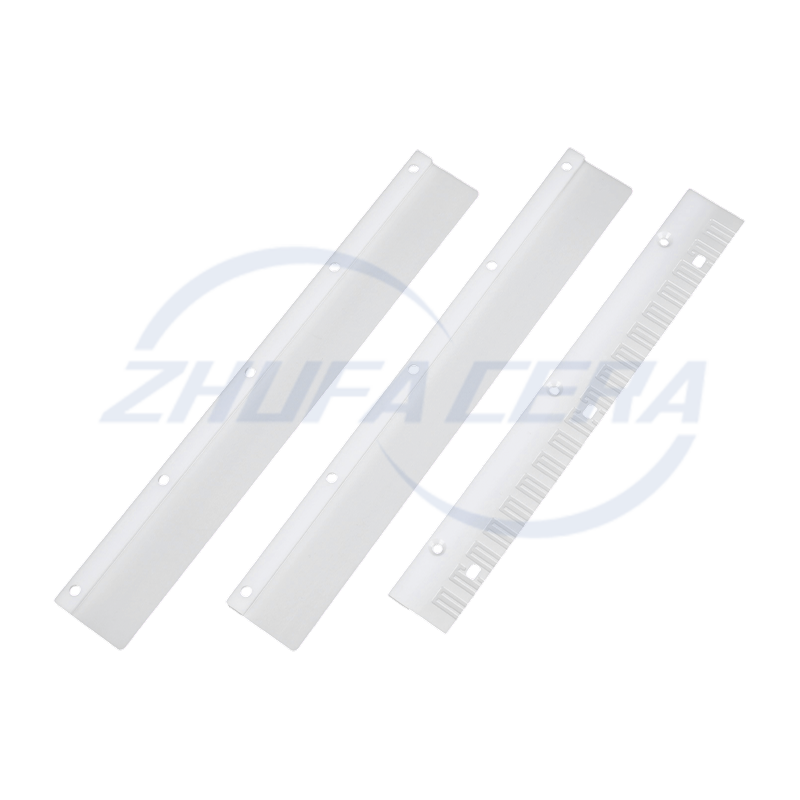

Ceramic sheets’ inherent hardness and brittleness make precision machining a major challenge—even minor errors can render parts unusable, especially for applications like semiconductor substrates requiring ±0.002mm tolerance . CNC machining with diamond-coated tools is the industry standard, as diamond’s hardness (≈10000HV) withstands abrasion from ceramic materials . High-speed spindles (up to 40000rpm) and micro-cutting techniques (0.01-0.05mm per pass) reduce tool wear and material chipping .

Advanced equipment configurations further enhance precision: air static pressure guideways minimize friction, while grating rulers with ±0.0001mm resolution enable real-time position correction . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. supports non-standard processing and small-batch proofing, leveraging such precision machining capabilities to meet industrial customers’ strict requirements for sheet flatness, surface roughness, and dimensional accuracy .

How to Implement Effective Quality Inspection for Ceramic Sheets?

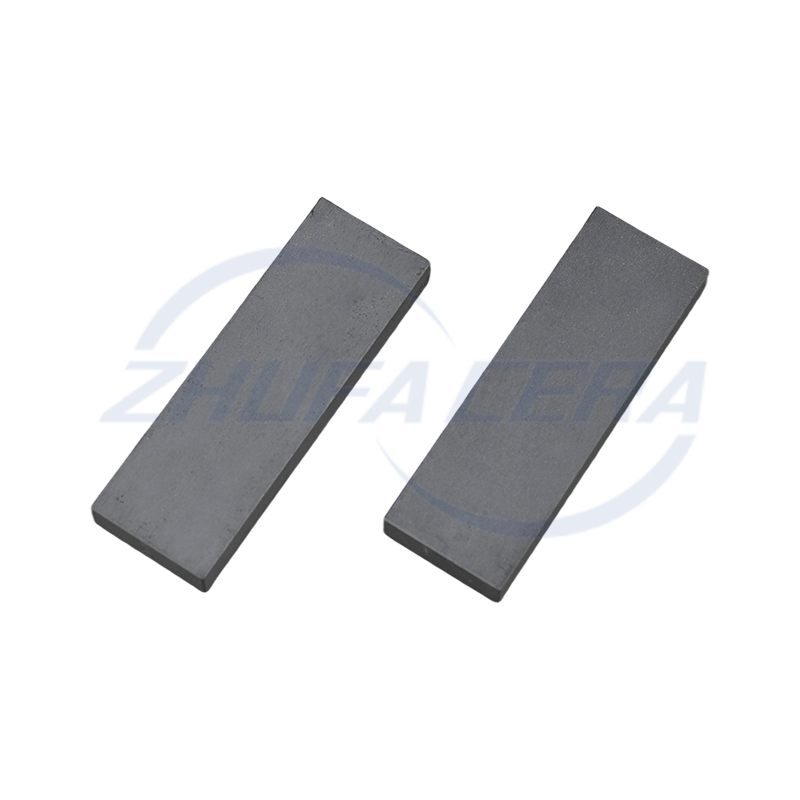

Quality inspection ensures ceramic sheets meet performance and reliability standards, covering both material properties and dimensional precision. For raw materials, powder purity, particle size uniformity, and slurry moisture content are rigorously tested—any deviation can cause structural defects . Post-manufacturing, advanced tools like Zeiss coordinate measuring machines detect dimensions with 0.7μm accuracy, while surface profilometers verify roughness (critical for optical or sealing sheets) .

Comprehensive inspection also includes performance testing: thermal conductivity for aluminum nitride sheets, hardness for alumina sheets, and corrosion resistance for silicon carbide sheets . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. maintains strict quality control standards throughout production, from raw material incoming checks to finished product testing, ensuring each ceramic sheet’s performance and reliability .

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어