Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

What Exactly are Magnesium - stable Zirconia Ceramics?

Magnesium - stable zirconia ceramics are a special type of advanced ceramic material. Their main components are zirconia (ZrO₂) and magnesium oxide (MgO). Zirconia, in its pure form, has multiple crystal structures that transform with temperature changes, which can cause volume changes and lead to material cracking. However, when magnesium oxide is added as a stabilizer, it plays a crucial role. Magnesium ions enter the zirconia lattice, stabilizing the crystal structure, usually in the cubic or tetragonal phase over a wide temperature range. This stable structure endows the ceramics with excellent properties. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd., with its focus on new ceramic materials production, is well - versed in the manufacturing process of magnesium - stable zirconia ceramics. They can precisely control the ratio of zirconia and magnesium oxide during production, ensuring the stability and high - quality performance of the final products.

How is Magnesium - stable Zirconia Ceramics Produced?

Raw Material Preparation

The production of magnesium - stable zirconia ceramics starts with high - purity zirconia powder as the base material. This zirconia powder is usually obtained through chemical methods such as precipitation, hydrolysis, or sol - gel processes. For example, in the precipitation method, zirconium salts like zirconium oxychloride react with precipitating agents in a solution to form zirconium hydroxide precipitates, which are then calcined to obtain zirconia powder. High - purity zirconia powder ensures the excellent performance of the final ceramics.

Magnesium oxide, used as an additive for stabilization, can be sourced from magnesium - containing minerals like magnesite (MgCO₃) or prepared through chemical synthesis methods. Before use, both the zirconia powder and magnesium oxide need to be pre - treated. They are often ground to achieve a uniform particle size distribution, which is crucial for the homogeneous mixing of the two components. This homogeneous mixing is essential as it directly affects the stability of the crystal structure in the final product. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. strictly controls the quality of raw materials, ensuring that the sourced zirconia powder and magnesium oxide meet high - purity standards, and their pre - treatment processes are precisely carried out to guarantee the quality of subsequent production.

Shaping Processes

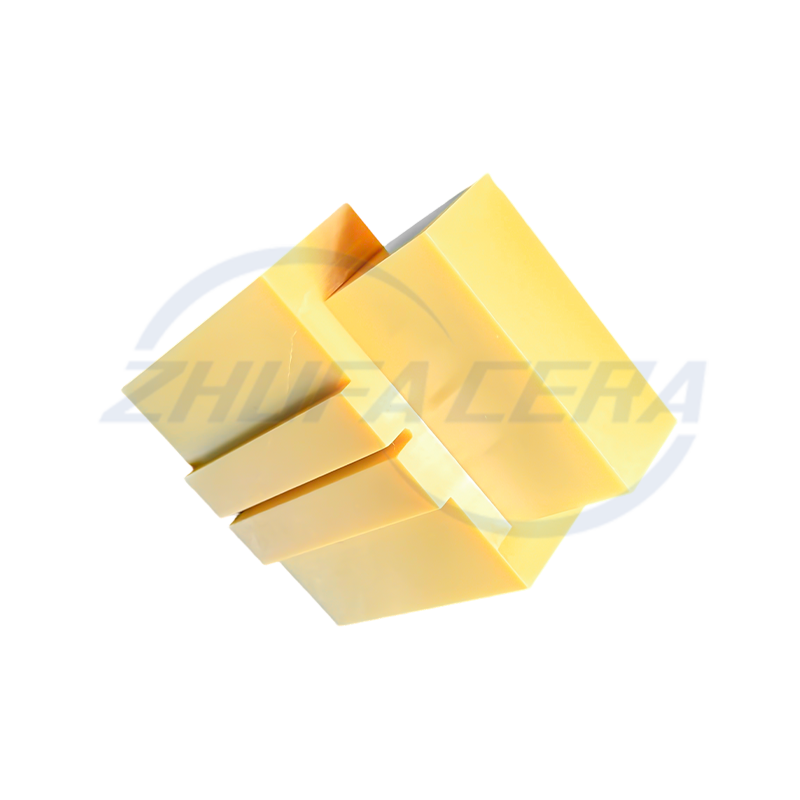

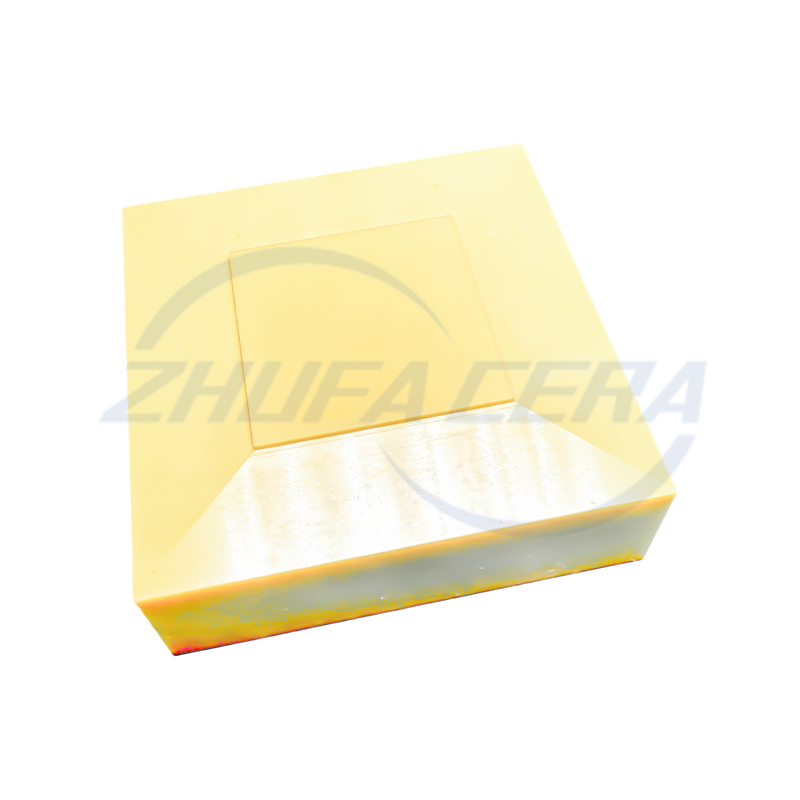

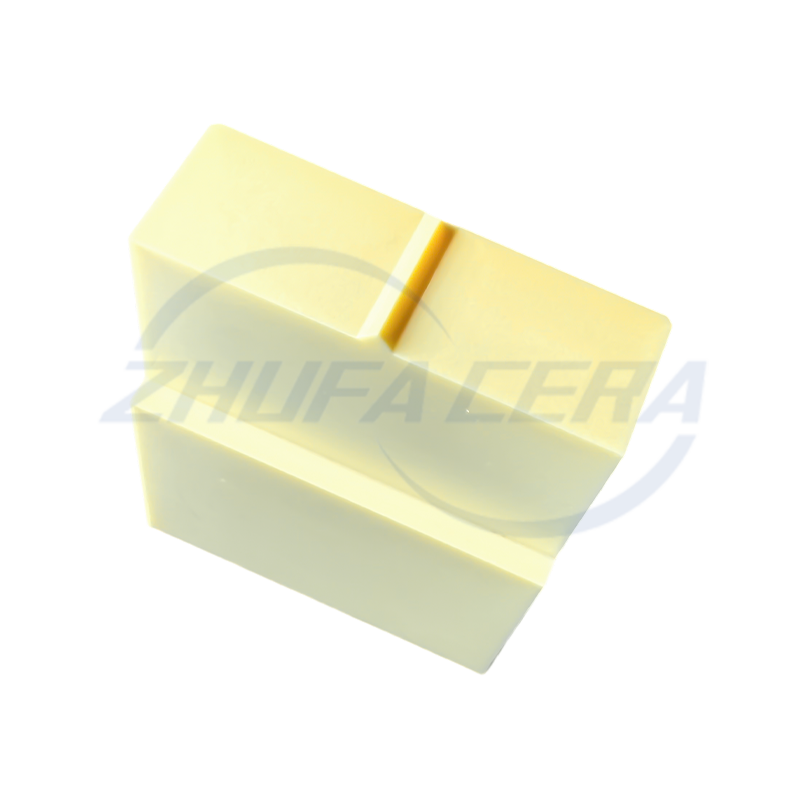

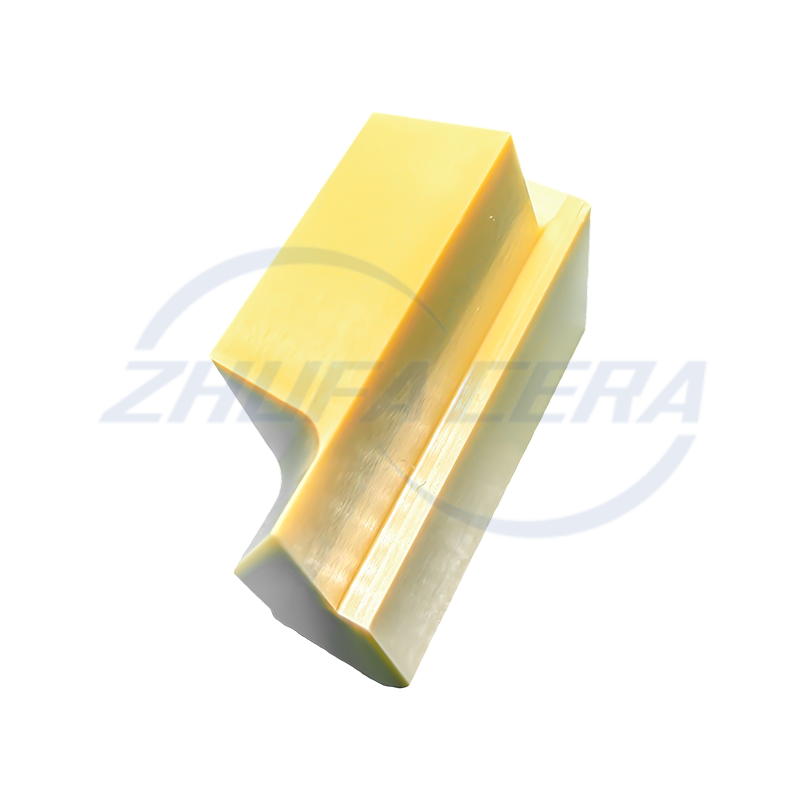

Several shaping processes are commonly employed in the production of magnesium - stable zirconia ceramics. Dry pressing is one of the widely used methods. In dry pressing, the mixed zirconia and magnesium oxide powders, along with a small amount of binder, are placed in a mold. High pressure is then applied to compact the powders into the desired shape. The principle behind this is that the external pressure forces the powder particles to pack closely together, forming a green body with a certain strength and shape. For example, in the production of ceramic parts with simple geometric shapes like discs or blocks, dry pressing can be an efficient and cost - effective way.

Cold isostatic pressing is another important shaping technique. In this process, the powder mixture is placed in a flexible rubber or plastic mold. The mold is then immersed in a liquid medium, and high hydrostatic pressure is applied uniformly from all directions. This uniform pressure allows the powder to be compacted evenly, resulting in a more homogeneous green body with better density distribution compared to dry pressing. Cold isostatic pressing is especially suitable for producing complex - shaped or large - sized ceramic components, where uniform compaction is crucial. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. is equipped with advanced dry pressing and cold isostatic pressing equipment, which can meet the shaping requirements of different types of magnesium - stable zirconia ceramic products, whether they are simple - shaped components for general applications or complex - shaped parts for high - end industries.

Sintering Process

The sintering process plays a key role in the production of magnesium - stable zirconia ceramics. After shaping, the green body has a relatively low density and strength. Sintering is carried out to increase the density and strength of the ceramic. During sintering, the green body is heated to a high temperature, typically above 1400°C in the case of magnesium - stable zirconia ceramics. At this high temperature, the powder particles bond together through diffusion, reducing the porosity of the material and enhancing its mechanical properties.

Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. has state - of - the - art high - temperature sintering furnaces in its manufacturing base. These furnaces can precisely control the heating rate, holding time, and cooling rate during sintering. Precise control of these parameters is essential for obtaining high - quality magnesium - stable zirconia ceramics. For example, a proper heating rate can prevent the formation of cracks in the ceramic due to thermal stress, and an appropriate holding time at the high - temperature stage ensures sufficient densification. The company's strict process control in sintering enables it to produce magnesium - stable zirconia ceramics with excellent density, strength, and other performance characteristics, meeting the high - quality requirements of various industries.

What are the Unique Properties?

High Mechanical Strength

Magnesium - stable zirconia ceramics possess high mechanical strength, which is mainly attributed to their unique crystal structure. The addition of magnesium oxide stabilizes the zirconia crystal structure, forming a more compact and ordered lattice. This tight crystal structure enables the ceramics to withstand large external forces without being easily damaged. For example, in the manufacturing of mechanical parts such as bearings or gears, magnesium - stable zirconia ceramics can endure high - pressure and high - load working conditions. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. ensures that the magnesium - stable zirconia ceramic products they produce have excellent mechanical strength through strict control of the production process, which meets the high - strength requirements of various mechanical applications.

Excellent Thermal Stability

These ceramics exhibit excellent thermal stability. They can maintain stable performance in high - temperature environments. The stable crystal structure formed by magnesium - oxide - stabilized zirconia effectively inhibits the transformation of the zirconia crystal structure with temperature changes, thus avoiding problems such as deformation and performance degradation caused by temperature changes. In high - temperature equipment components, like furnace linings or heat - resistant fixtures in high - temperature furnaces, magnesium - stable zirconia ceramics can work stably at high temperatures, ensuring the normal operation of the equipment. Zhejiang Zhufa Precision Ceramics Technology Co., Ltd.'s high - temperature sintering furnaces and precise process control during production contribute to the outstanding thermal stability of their magnesium - stable zirconia ceramic products, making them suitable for a wide range of high - temperature applications.

Good Chemical Resistance

Magnesium - stable zirconia ceramics have good chemical resistance. They can resist the erosion of various chemical substances. This is because the chemical bonds in their crystal structure are relatively stable and are not easily broken by chemical reactions with common acids, alkalis, and salts. In chemical equipment, such as reaction vessels, pipelines, or valves in the petrochemical industry, magnesium - stable zirconia ceramics can maintain their integrity and performance for a long time in complex chemical environments, reducing the frequency of equipment maintenance and replacement, and thus extending the service life of the equipment. The high - quality raw materials and strict production processes of Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. ensure that the magnesium - stable zirconia ceramic products have reliable chemical resistance, which can meet the needs of harsh chemical environments in different industries.

Where are They Applied?

Automotive Industry

Magnesium - stable zirconia ceramics find extensive applications in the automotive industry. In engine components, they can be used to manufacture parts such as cylinder liners. Their high mechanical strength and wear - resistance enable the engine to operate under high - pressure and high - temperature conditions for a long time, reducing friction and wear between components, and thus improving the engine's efficiency and durability. For sensors, magnesium - stable zirconia ceramics can be used in the housing or some internal structural parts. Their excellent thermal stability ensures that the sensors can work stably in high - temperature engine environments, accurately sensing physical quantities such as temperature and pressure, and providing reliable data for the vehicle's electronic control system.

Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. has provided magnesium - stable zirconia ceramic components for some automotive manufacturers. For example, their products are used in the braking systems of certain high - end cars. The wear - resistance and high - temperature resistance of magnesium - stable zirconia ceramics can withstand the high - temperature generated during frequent braking, ensuring the reliability and long - term performance of the braking system, thereby enhancing the safety of the vehicle.

Photovoltaic Industry

In the photovoltaic industry, magnesium - stable zirconia ceramics play an important role. In wafer cutting equipment, ceramic blades or guide rails made of magnesium - stable zirconia ceramics are used. Their high hardness and wear - resistance ensure accurate cutting of silicon wafers, reducing wafer breakage rates and improving production yields. In the coating process of photovoltaic cells, magnesium - stable zirconia ceramic fixtures can be used to hold the substrates stably. These fixtures can withstand high - temperature processing environments during coating, maintaining their shape and stability, which is conducive to the uniform deposition of coatings, improving the quality of photovoltaic cells, and ultimately enhancing the conversion efficiency of solar energy. In high - temperature sintering furnaces for photovoltaic materials, magnesium - stable zirconia ceramics can be used as furnace linings or support structures. Their excellent thermal stability and insulation properties can effectively reduce heat loss, improve the thermal efficiency of the sintering furnace, and ensure the normal progress of the high - temperature sintering process, which is crucial for the production of high - quality photovoltaic materials.

Petrochemical Industry

Petrochemical equipment often operates in complex chemical environments with high temperatures, high pressures, and corrosive media. Magnesium - stable zirconia ceramics are ideal materials for many components in this industry. In pumps, magnesium - stable zirconia ceramic impellers can be used. Their high mechanical strength and corrosion - resistance can withstand the erosion of chemical fluids, ensuring the long - term stable operation of the pump and reducing the need for frequent maintenance and replacement of impellers. For valves, ceramic valve seats and seals made of magnesium - stable zirconia ceramics are highly suitable. They can resist the corrosion of various chemical substances in petrochemical media, maintain good sealing performance under high - pressure conditions, and prevent leakage of media, which is of great significance for the safe operation of petrochemical production lines. In reactors, magnesium - stable zirconia ceramic linings can protect the reactor walls from corrosion, and their high - temperature resistance can also ensure the stability of the reaction environment, promoting the smooth progress of chemical reactions.

Semiconductor Industry

Semiconductor manufacturing requires extremely high - precision and reliable materials and components. Magnesium - stable zirconia ceramics meet many requirements in this field. In wafer handling equipment, such as robotic arms and wafer carriers, magnesium - stable zirconia ceramics can be used to make key components. Their high - purity property ensures that they will not introduce impurities into the semiconductor manufacturing process, which is crucial for maintaining the quality of semiconductor products. Their excellent insulation properties can prevent electrical interference, ensuring the normal operation of electrical components in the equipment. In etching and deposition equipment, magnesium - stable zirconia ceramic components are used to withstand the corrosive effects of various chemical gases and plasmas. Their wear - resistance and thermal stability can maintain the accuracy and stability of the equipment during long - term operation, ensuring the high - precision processing of semiconductor wafers, and thus improving the performance and yield of semiconductor devices.

Why Choose Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. for Magnesium - stable Zirconia Ceramics?

Strong Production Base

When it comes to producing magnesium - stable zirconia ceramics, Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. stands out with its state - of - the - art manufacturing base spanning 30,000㎡. This large - scale facility is equipped with a comprehensive set of core machinery that covers the entire production process, from the initial raw material processing to the final precision finishing.

For raw material processing, the company has advanced grinding and mixing equipment. These ensure that the high - purity zirconia powder and magnesium oxide are uniformly mixed, which is fundamental for the stability and quality of the final product. In the shaping stage, the presence of advanced dry pressing, cold isostatic pressing, and injection molding equipment allows for the production of magnesium - stable zirconia ceramics in various shapes and sizes. Whether it's a simple - shaped component for general industrial use or a complex - shaped part for high - end applications, the company can meet the requirements.

High - temperature sintering furnaces are crucial for densifying the ceramics. The company's sintering furnaces can precisely control temperature, heating rate, and holding time. This precision in sintering results in magnesium - stable zirconia ceramics with dense and stable ceramic bodies, ensuring excellent mechanical and thermal properties. To achieve high - precision finishing, the plant is also equipped with CNC engraving machines, surface grinders, centerless grinders, pin grinders, and honing machines. With such a well - equipped production base and a well - structured production workflow, the company can produce millions of precision ceramic parts annually. This not only guarantees high - volume production but also enables rapid prototyping and flexible manufacturing to meet diverse client requirements.

Efficient and Responsive Service System

Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. adopts a customer - centric approach, which is highly beneficial when sourcing magnesium - stable zirconia ceramics. The company's efficient service system and agile manufacturing capabilities enable it to quickly respond to different client needs.

From the initial custom prototyping stage, the company's technical team can work closely with clients. They can understand the specific requirements of clients, such as the desired performance characteristics, dimensions, and surface finishes of the magnesium - stable zirconia ceramic products. Based on this understanding, they can provide professional advice on product design optimization. For example, if a client needs a ceramic component for a high - temperature application, the company's engineers can suggest design modifications to enhance the thermal stability of the component.

During small - batch trials, the company can quickly produce samples for clients to test and evaluate. This shortens the development cycle, allowing clients to make decisions promptly. Once the design is finalized, the company can smoothly transition to large - scale production, ensuring consistent lead times. The company also collaborates with clients on process improvements. By analyzing the production process, they can find ways to reduce costs without sacrificing product quality. This collaborative approach helps clients enhance their competitiveness in the market, making Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. a reliable partner for magnesium - stable zirconia ceramics.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어