Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

Ceramic Plungers: Key Manufacturing Insights into New Ceramic Materials

Which New Ceramic Materials Dominate Ceramic Plunger Production?

The performance of ceramic plungers is fundamentally determined by their base materials, with several advanced ceramic varieties leading industrial applications. Zirconium oxide (zirconia) stands out for its exceptional toughness, corrosion resistance, and high-temperature stability—properties that make it ideal for precision scenarios like diesel injector valves, where it enables tight tolerances (down to ±0.005 mm) and reliable fuel atomization. Aluminum oxide (alumina), especially grades with over 90% purity, is valued for its cost-effectiveness paired with strong wear resistance and hardness (≥80 HRA), making it a staple in slurry piston pumps and general industrial equipment.

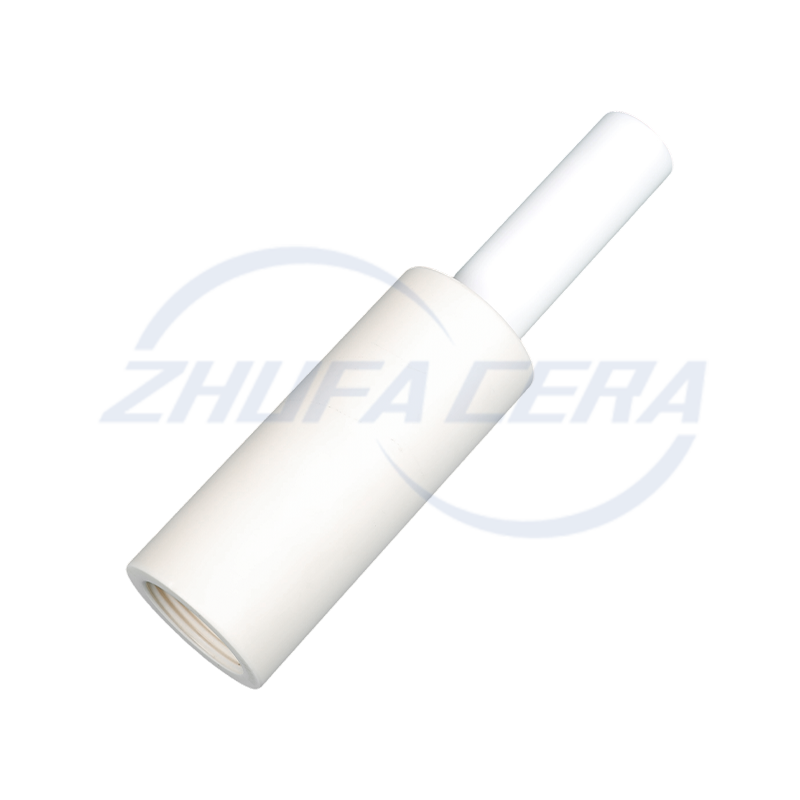

For applications demanding balanced performance, zirconia-toughened alumina (ZTA) combines alumina’s hardness with zirconia’s toughness, resisting crack propagation through phase transformation and excelling in high-stress environments. Specialized scenarios also leverage materials like silicon carbide and silicon nitride for their extreme thermal shock resistance and mechanical strength, though these are typically deployed in niche high-demand settings. Suppliers like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. offer comprehensive solutions across these materials, catering to diverse industrial needs from standard to custom requirements.

How Do Advanced Manufacturing Processes Ensure Ceramic Plunger Performance?

Precision and durability in ceramic plungers rely on rigorous, technology-driven manufacturing workflows, with every step critical to final quality. Material preparation begins with ultra-fine powder processing—controlling particle size and distribution to avoid pores that compromise strength. Molding technologies have evolved significantly: gel forming, for instance, creates denser structures by using polymer crosslinking to fix ceramic particles in place, eliminating voids and enhancing dimensional accuracy. This method aligns with the process rigor emphasized by manufacturers like Zhejiang Zhufa, which prioritizes detail control from equipment setup onward.

Sintering follows, with temperature and atmosphere tightly regulated to achieve full density—zirconia plungers, for example, require precise sintering to maintain their tetragonal phase and toughness. The final critical step is precision machining: high-precision inner and outer cylindrical grinders create mirror-like surfaces (Ra 0.1 μm) that reduce friction and enable tight sealing, while processes like vibration polishing enhance cleanability for medical and food industry applications. For composite plungers, ceramic metallization bonding and welding technologies join ceramic casings to metal cores (e.g., GB 45 steel), merging ceramic’s performance with metal’s structural support.

What Quality Control Standards Guarantee Ceramic Plunger Reliability?

Ceramic plungers operate in harsh conditions—high pressure, corrosive chemicals, extreme temperatures—making strict quality control non-negotiable. Dimensional inspection is foundational: advanced metrology tools verify tolerances as tight as 0.001 mm, ensuring compatibility with precision systems like dosing pumps and diesel injectors. Material performance testing is equally critical: hardness (often ≥9 on the Mohs scale for zirconia), flexural strength (exceeding 1200 MPa for premium zirconia), and corrosion resistance (tested against acids, alkalis, and saline solutions) are validated to meet industry benchmarks.

Process-level quality checks include porosity analysis to confirm dense structures and surface finish testing to ensure self-lubricating microporous properties or mirror surfaces as required. Manufacturers like Zhejiang Zhufa integrate these checks throughout production, from raw material inbound inspection to final product validation, ensuring each plunger meets performance and reliability standards. For custom orders, additional application-specific testing—such as thermal shock resistance for high-temperature pumps—further guarantees fit-for-purpose performance.

How to Address Custom Ceramic Plunger Requirements Effectively?

Custom ceramic plungers demand a balance of material expertise, process flexibility, and engineering collaboration. The first step is material selection tailored to the application: zirconia for corrosion-prone environments like chemical dosing, alumina for cost-sensitive wear applications, and ZTA for high-strength, high-toughness needs. Suppliers with cross-industry expertise, such as Zhejiang Zhufa, can guide this selection based on factors like operating temperature (up to 1650°C for zirconia), pressure (≤10 MPa for standard alumina plungers), and chemical exposure.

Design collaboration is critical for non-standard requirements—engineers must account for ceramic’s brittleness by optimizing geometries, while integrating features like hollow cores or metal bonding for weight reduction or structural support. Flexible manufacturing capabilities, including small-batch proofing, allow validation of designs before full production, reducing risks. In-house manufacturing facilities further ensure control over lead times and quality, as seen in providers that handle everything from powder processing to precision machining internally.

Finally, post-delivery support—such as guidance on maintenance (e.g., proper cleaning of mirror surfaces) or troubleshooting—completes the custom service cycle. This end-to-end approach, combining material knowledge, process flexibility, and engineering support, ensures custom ceramic plungers meet the unique performance, precision, and efficiency needs of industrial customers.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어