Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

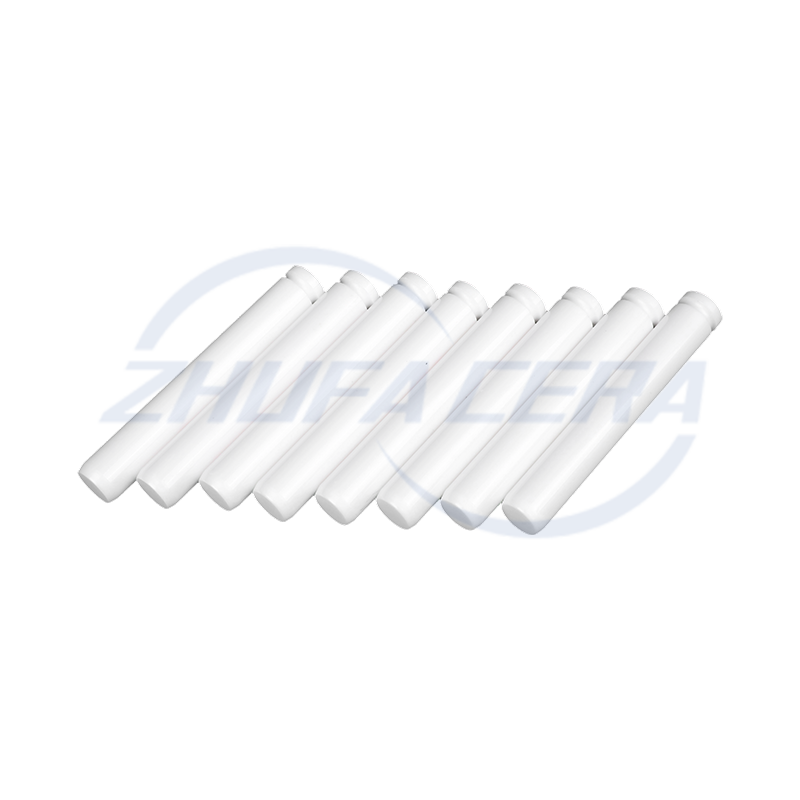

Ceramic Rods: Practical Manufacturing & Application Insights

What Ceramic Materials Are Suitable for Making Ceramic Rods, and How to Choose Them?

Ceramic rods are not a one-size-fits-all product—their material selection depends entirely on the application’s performance requirements. The most common materials used include alumina (Al₂O₃), zirconia (ZrO₂), silicon nitride (Si₃N₄), and silicon carbide (SiC), each with distinct properties that align with specific industrial needs.

Alumina ceramic rods are the most cost-effective option, offering good hardness (Mohs 9) and insulation (volume resistivity >10¹⁴ Ω·cm) at room temperature, making them ideal for low-load applications like photovoltaic wafer cutting guides. Zirconia rods, by contrast, excel in wear resistance and toughness (fracture toughness ~10 MPa·m¹/²), suiting high-impact scenarios such as automotive sensor shafts. Silicon nitride rods stand out for high-temperature resistance (up to 1600℃) and thermal shock resistance, making them a top choice for petrochemical reactor internals. Silicon carbide rods, meanwhile, combine high hardness with corrosion resistance, perfect for semiconductor wafer handling tools.

Zhejiang Zhufa Precision Ceramics Technology Co., Ltd., a China-based precision ceramics manufacturer, offers all these material options as part of its advanced ceramic solutions. For clients unsure of material selection, Zhufa leverages its cross-industry expertise to match ceramic rod materials to specific use cases—for example, recommending alumina for cost-sensitive photovoltaic applications and zirconia for high-wear automotive components—ensuring each rod meets performance, precision, and efficiency needs.

What Key Manufacturing Processes Determine the Quality of Ceramic Rods?

The manufacturing of ceramic rods is a multi-step process where precision at each stage directly impacts the final product’s straightness, dimensional accuracy, and mechanical strength. The core steps include raw material preparation, molding, sintering, and precision finishing—all of which require strict control.

Raw material preparation starts with grinding ceramic powder to a uniform particle size (typically 0.5-5 μm); uneven particle sizes can lead to voids in the rod after sintering. Next, molding methods are chosen based on rod diameter and length: for small-diameter rods (≤10 mm), extrusion molding is preferred for high efficiency, while cold isostatic pressing (CIP) is used for larger-diameter rods (≥20 mm) to ensure uniform density. Zhejiang Zhufa’s 30,000㎡ manufacturing base is equipped with advanced extrusion and CIP equipment, enabling it to produce rods ranging from 1 mm to 100 mm in diameter.

Sintering is the critical step that densifies the ceramic: temperatures range from 1600℃ for alumina to 2200℃ for silicon carbide, with a slow heating rate (2-5℃/min) to prevent warping. Post-sintering finishing uses centerless grinders and surface grinders—equipment Zhufa also houses—to achieve straightness tolerance of ≤0.1 mm/m and surface roughness (Ra) of ≤0.4 μm. This level of precision is essential for applications like semiconductor wafer handling, where even minor deviations can cause process errors.

How to Ensure Dimensional Precision and Straightness of Ceramic Rods?

Dimensional precision and straightness are non-negotiable for ceramic rods, especially in industries like automotive and semiconductors where rods act as guides, shafts, or structural components. The main challenges include controlling sintering shrinkage (which can be 15-25% depending on the material) and minimizing warping during cooling.

To address sintering shrinkage, manufacturers use pre-sintered “green rods” with oversized dimensions—calculated based on the material’s shrinkage rate. For example, a zirconia rod that needs to be 10 mm in diameter after sintering will have a green rod diameter of ~12.5 mm (accounting for 20% shrinkage). Zhejiang Zhufa, which supports non-standard processing, tailors this oversized design to each client’s specific rod dimensions, ensuring the final product meets exact specifications.

Straightness control relies on two measures: using a flat, heat-resistant sintering fixture to prevent rod bending during sintering, and post-sintering straightening via precision grinding. Zhufa uses centerless grinders with computer numerical control (CNC) to achieve consistent straightness—for automotive fuel cell rods, it maintains a straightness tolerance of ≤0.05 mm/m, which is critical for ensuring proper fuel flow. Additionally, its strict quality control system includes 100% dimensional inspection using laser micrometers and straightness testers, catching any deviations before delivery.

What Industrial Applications Rely on Ceramic Rods, and What Performance Requirements Do They Have?

Ceramic rods are integral to four key industries, each with unique performance demands that dictate material and manufacturing choices:

Automotive Industry: Rods are used in sensors, fuel cells, and braking systems. For example, zirconia rods in brake caliper guides need wear resistance (volume wear rate <1×10⁻⁶ mm³/(N·m)) and high-temperature resistance (up to 300℃). Zhufa’s ceramic rods meet these requirements, helping improve automotive safety and durability—key for new energy and smart car development.

Photovoltaic Industry: Alumina rods act as guides in wafer cutting equipment, requiring good insulation (to avoid electrostatic damage to wafers) and wear resistance (to withstand abrasive cutting fluids). Zhufa’s alumina rods have a volume resistivity of >10¹⁴ Ω·cm and Ra ≤0.4 μm, ensuring stable wafer cutting and extending equipment life.

Petrochemical Industry: Silicon nitride rods are used in reactor agitator shafts, needing corrosion resistance (to withstand acidic/alkaline media) and high-temperature resistance (up to 1200℃). Zhufa’s silicon nitride rods meet these criteria, reducing maintenance costs by resisting chemical degradation better than metal alternatives.

Semiconductor Industry: High-purity alumina or silicon carbide rods are used in wafer handling, requiring ultra-low particle generation (≤1 particle/cm² per hour) and high straightness. Zhufa’s in-house manufacturing, which includes cleanroom processing for high-purity ceramics, ensures these rods meet semiconductor industry standards, reducing pollution risks during etching or deposition.

Why Choose Custom Ceramic Rod Services, and What Advantages Do They Offer?

Off-the-shelf ceramic rods often fail to meet the unique needs of industrial clients—whether due to non-standard dimensions, specific material requirements, or tight precision tolerances. Custom services, like those offered by Zhejiang Zhufa Precision Ceramics, address these gaps with three key advantages:

Fully in-house manufacturing eliminates reliance on third-party suppliers, allowing for faster lead times—Zhufa can deliver small-batch custom rods (as few as 10 pieces) in 2-4 weeks, supporting clients’ prototyping needs. Low-volume & multi-type capabilities mean clients can order rods of different materials, diameters, and lengths in the same batch, reducing procurement complexity. Direct engineering support helps optimize rod design: for example, Zhufa’s team might suggest adding a chamfer to a semiconductor rod to prevent wafer scratches, or adjusting sintering parameters for a petrochemical rod to enhance corrosion resistance.

Zhufa’s customer-centric approach, which includes full-process services from design to delivery, ensures custom rods align with clients’ exact application needs. This flexibility not only saves time and cost but also helps clients enhance their market competitiveness—by using ceramic rods tailored to their equipment, they can improve performance, reduce downtime, and extend product life.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어