Email: zf@zfcera.com

Email: zf@zfcera.com

Telephone: +86-188 8878 5188

Telephone: +86-188 8878 5188

Advanced Ceramics: Focus on the Manufacturing of New Ceramic Materials

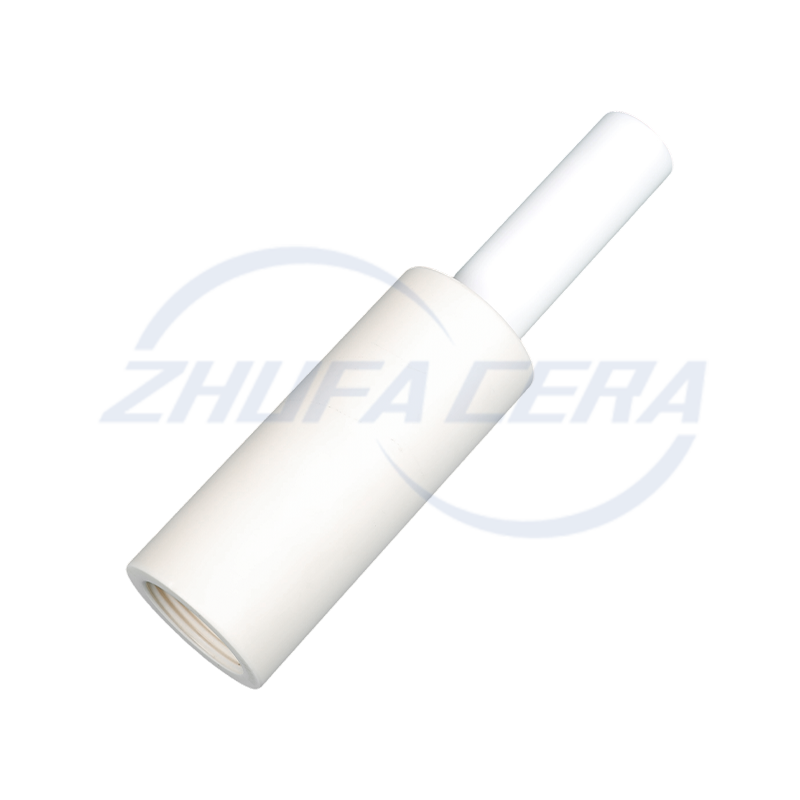

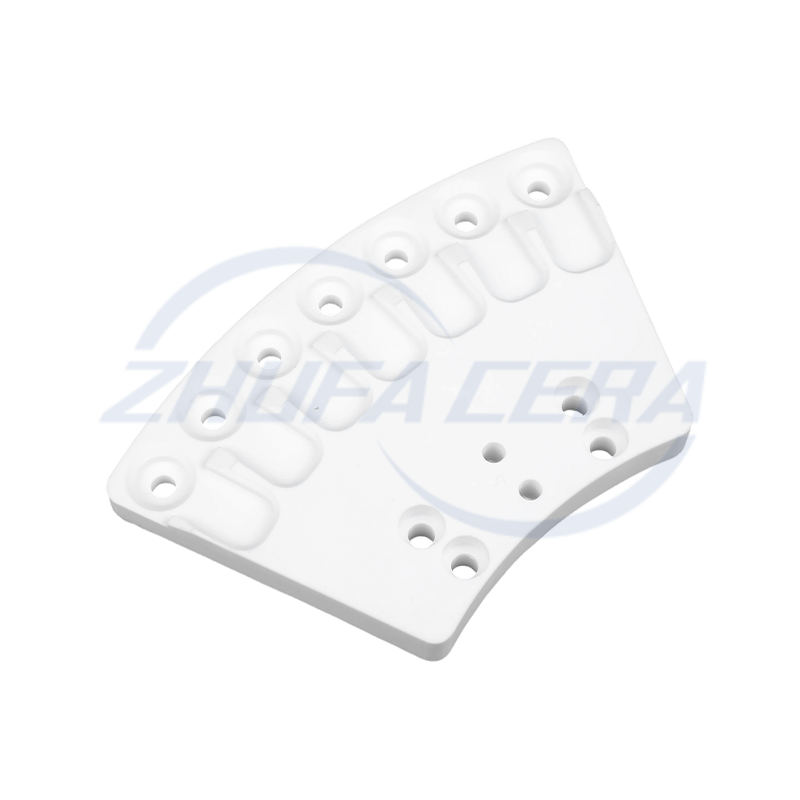

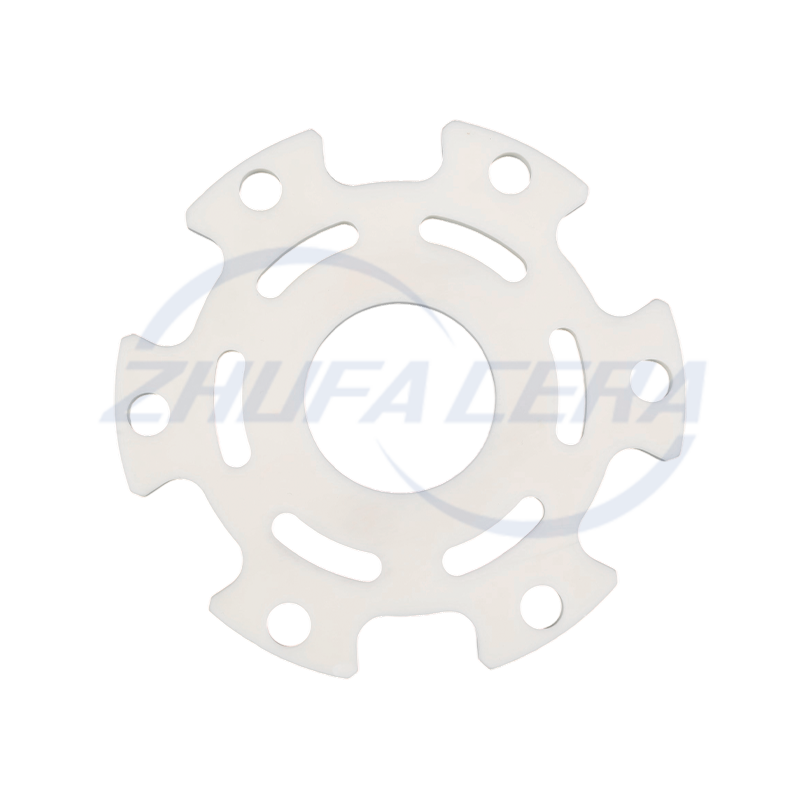

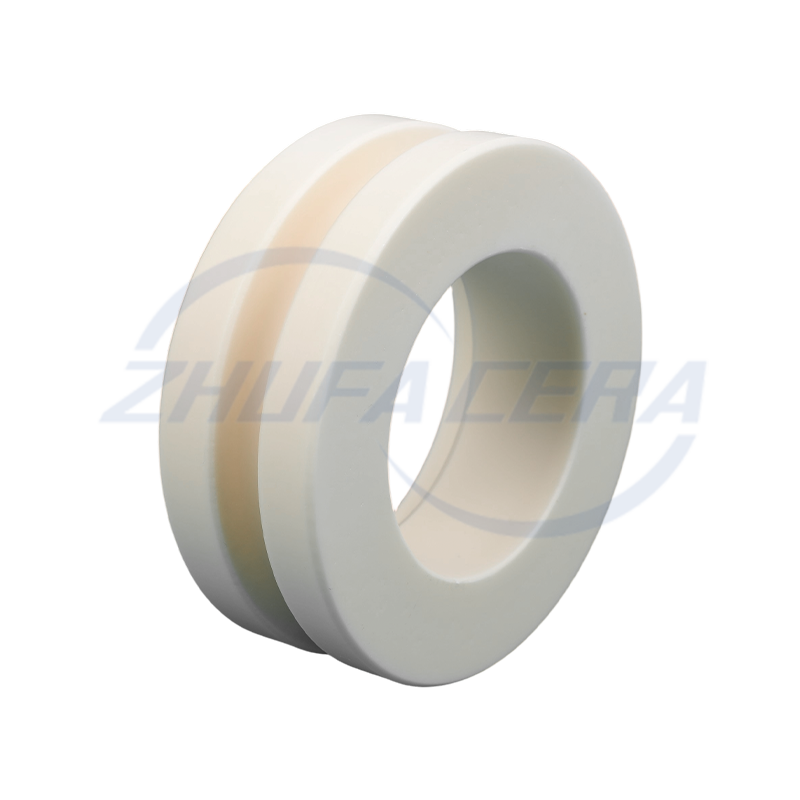

Advanced ceramics, also known as precision ceramics or engineering ceramics, represent a class of high-performance inorganic non-metallic materials engineered for extreme industrial demands. Unlike traditional ceramics, these materials are crafted from high-purity synthetic powders (such as zirconium oxide, aluminum oxide, and silicon nitride) through precision-controlled manufacturing processes, delivering exceptional properties including high temperature resistance, corrosion resistance, wear resistance, and insulation. As a cornerstone of high-end manufacturing, the production of new ceramic materials has become a strategic focus in global industrial competition, with Chinese enterprises like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. emerging as key players in bridging technical gaps and meeting customized industrial needs.

Core Manufacturing Process of New Ceramic Materials

The manufacturing of new ceramic materials is a sophisticated, multi-stage process where each link directly determines the final product's performance and precision. From powder preparation to precision finishing, strict process control is essential to overcome the inherent brittleness of ceramic materials and achieve industrial-grade reliability.

1. Powder Preparation: The Foundation of Material Performance

High-quality ceramic powder is the prerequisite for superior new ceramic materials. The powder's purity, particle size distribution, and uniformity directly influence the sintering behavior and mechanical properties of the final product. Industry standards demand ultra-fine particles (often below 1μm) with narrow size distribution to ensure consistent densification during sintering.

Zhejiang Zhufa, as a source factory specializing in new ceramic materials, prioritizes powder quality control as the starting point of its manufacturing system. The company's material portfolio covers key ceramic powders including zirconium oxide, aluminum oxide, aluminum nitride, silicon nitride, and silicon carbide—each selected and processed to meet the specific performance requirements of downstream applications, from semiconductor equipment to new energy vehicles.

2. Forming Technology: Shaping the Future of Ceramic Components

Forming is the critical step that transforms ceramic powder into green bodies with predefined shapes, and its advancement directly dictates the complexity and precision of ceramic components. The industry primarily adopts two categories of forming technologies, each with distinct applications:

Wet Forming

This method involves mixing ceramic powder with a solvent to create a slurry, which is then injected into molds. Key techniques include:

Injection Molding: Regarded as the primary process for producing high-precision ceramic parts, it excels at creating components with complex features (e.g., holes, grooves) while ensuring dimensional accuracy and density uniformity. This "near-net shaping" technology minimizes subsequent machining, reducing the risk of microcracks in brittle ceramic materials.

Gel Injection Molding: A advanced colloidal forming technology that uses low organic content (5-10 times less than injection molding) to reduce cracking risks during binder removal. It is widely applied to oxides and non-oxides like alumina and silicon carbide.

Dry Forming

This process uses minimal binders and relies on pressure to shape dry powder, including:

Cold Isostatic Pressing: A mature technology that applies uniform pressure to flexible molds, producing green bodies with higher uniformity than uniaxial pressing. It is widely used for manufacturing alumina vacuum switch shells and zirconia axis sleeves.

Dry Pressing: Suitable for simple, thin-walled parts and enables large-scale production but is limited by shape complexity.

Zhejiang Zhufa has built a comprehensive forming capability in its 30,000㎡ manufacturing base, equipped with advanced dry pressing, cold isostatic pressing, and injection molding equipment. This multi-technology layout allows the company to handle diverse requirements, from simple structural parts to complex precision components, and supports non-standard processing and small-batch proofing for industrial customers.

3. Sintering: Achieving Densification and Performance

Sintering is the "metamorphosis" stage where green bodies are heated to high temperatures (typically 1400-1800°C) to achieve densification. During this process, powder particles bond together, and the material shrinks by 15-25%—controlling this shrinkage and avoiding defects like cracking or deformation is a major industry challenge.

Key sintering technologies include:

Atmospheric Sintering: The most common method, using controlled gas environments (e.g., nitrogen for silicon nitride) to prevent oxidation.

Hot Isostatic Pressing (HIP): Combines high temperature and high pressure (100-200 MPa) to eliminate internal pores, producing ultra-dense ceramics with superior mechanical properties. This technology is critical for high-performance materials like silicon nitride ceramic used in IGBT modules.

Zhejiang Zhufa's manufacturing base is equipped with high-temperature sintering furnaces to ensure dense and stable ceramic bodies. By precisely controlling sintering temperature, holding time, and atmosphere, the company guarantees the performance consistency of materials like silicon nitride (for thermal shock resistance) and aluminum nitride (for thermal conductivity).

4. Precision Finishing: Meeting Micron-Level Requirements

Advanced ceramics' high hardness (often exceeding HRC 60) makes post-sintering processing extremely challenging, requiring specialized equipment and tools. Precision finishing typically uses diamond grinding tools and CNC technology to achieve dimensional accuracy of ±0.01mm or higher—essential for applications like semiconductor wafer handling and sensor components.

Zhejiang Zhufa addresses this challenge with a full set of precision processing equipment, including CNC engraving machines, surface grinders, centerless grinders, and honing machines. This end-to-end processing capability ensures that even complex components meet strict precision standards, supporting its annual production of millions of precision ceramic parts.

Key Technical Challenges in New Ceramic Material Manufacturing

Despite technological advancements, the manufacturing of new ceramic materials still faces industry-wide bottlenecks that test enterprises' technical capabilities:

1. Powder Quality Control

High-purity, ultra-fine powders (especially for advanced non-oxides) remain a pain point, with some high-end powders still relying on imports. Zhejiang Zhufa mitigates this by establishing strict powder sourcing and pre-processing standards, ensuring raw material consistency for its core product lines.

2. Process Consistency

Batch-to-batch variation in performance is a persistent issue due to the sensitivity of ceramic manufacturing to process parameters. Zhejiang Zhufa addresses this through a strict quality control system covering equipment configuration to inspection, adhering to technology-driven standards to ensure product reliability.

3. Cost-Efficiency Balance

Advanced ceramic manufacturing involves high equipment investment (e.g., HIP furnaces) and material costs, limiting widespread adoption. Zhejiang Zhufa optimizes this balance through in-house manufacturing and process optimization, reducing intermediate links and offering cost-effective solutions without compromising performance.

Application-Driven Manufacturing and Enterprise Practice

The value of new ceramic materials lies in their application, and manufacturing technologies are increasingly driven by downstream industry needs. Key application fields and corresponding manufacturing requirements include:

1. New Energy Vehicles

Components like engine parts, brake systems, and IGBT substrates require wear resistance, high temperature resistance, and thermal conductivity. Zhejiang Zhufa's zirconia and silicon nitride ceramics are widely used in these areas, improving vehicle performance, safety, and durability while supporting new energy vehicle development.

2. Semiconductor Equipment

Wafer handling and etching components demand high purity (≥99.99%), insulation, and particle-free surfaces. The company's high-purity alumina and silicon carbide ceramics meet these requirements, ensuring process accuracy and reducing pollution risks in semiconductor manufacturing.

3. Photovoltaic Manufacturing

Wafer cutting and sintering equipment components need to withstand high temperatures and repeated wear. Zhejiang Zhufa's ceramic solutions enhance production efficiency and extend equipment life in harsh photovoltaic manufacturing environments.

4. Petrochemical Industry

Pumps, valves, and seals require extreme corrosion and wear resistance. The company's corrosion-resistant ceramics ensure reliable operation in complex chemical environments, reducing maintenance costs for customers.

The Role of Integrated Manufacturing in Market Competition

In the fiercely competitive advanced ceramics market—dominated by international giants like Japan's Kyocera and America's CoorsTek—Chinese enterprises are breaking through by leveraging integrated manufacturing and customized services. Zhejiang Zhufa's competitive advantages reflect this trend:

Fully In-House Manufacturing: Covering powder processing, forming, sintering, and finishing, the company controls every quality link and shortens lead times.

Application-Centric Customization: With cross-industry expertise, it collaborates closely with clients on design optimization and process improvement, reducing costs and development cycles.

Agile Service System: From prototyping to mass production, the company's responsive service meets diverse needs, enhancing customer competitiveness.

Future Trends in New Ceramic Material Manufacturing

The manufacturing of new ceramic materials is evolving toward higher performance, greater complexity, and smarter production:

1. Material Innovation

Development of composite ceramics (e.g., ceramic-metal composites) and functionally graded materials to expand application boundaries.

2. Process Advancement

Ceramic 3D printing (e.g., stereolithography and selective laser sintering) is emerging as a game-changer, enabling the production of previously unmanufacturable complex structures.

3. Intelligent Manufacturing

Integration of AI and digital twin technology to optimize sintering and processing parameters, improving batch stability. Zhejiang Zhufa's structured production workflow lays the foundation for future intelligent upgrades.

As a critical material for high-end manufacturing, new ceramic materials' manufacturing level reflects a country's industrial strength. Enterprises like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd., through their focus on process refinement, equipment investment, and customer-centric services, are not only meeting current industrial demands but also driving the localization and advancement of China's advanced ceramics industry. For industrial customers with customized needs, partnering with such integrated manufacturers has become the key to obtaining high-performance, cost-effective ceramic solutions.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어