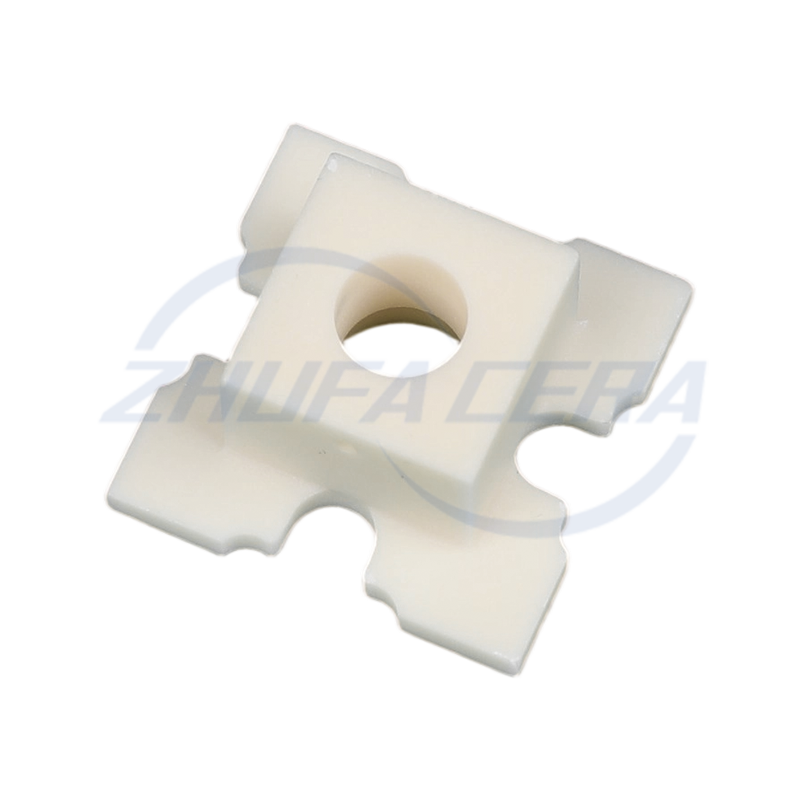

Custom Shape Alumina Ceramic Base is a non-standard customized ceramic base made of high-purity alumina material. Compared with traditional standard geometric ceramic parts, this product realizes the molding of complex three-dimensional contours through precision machining technology, which can accurately match the installation requirements of special equipment or devices. Its core advantage lies in combining the excellent physical properties of alumina ceramics (such as high hardness, high temperature resistance, and insulation) with personalized structural design. While maintaining the intrinsic properties of the material, it breaks through the shape limitations of conventional ceramic products and provides a more flexible solution for the field of high-end equipment manufacturing.

Material properties: Using alumina ceramics with a purity of more than 99.7%, Vickers hardness of 1800HV, operating temperature range of -196℃ to 1600℃, volume resistivity>10^14Ω·cm, with both mechanical strength and electrical insulation.

Precision molding: Using CNC machining and laser engraving technology, it can achieve dimensional accuracy control of ±0.02mm, and support the processing of complex curved surfaces, special-shaped holes and microstructures.

Customized design: Reverse engineering optimization is performed based on the 3D model provided by the customer to ensure that the assembly gap is ≤0.05mm, which is particularly suitable for scenes with strict requirements on installation accuracy, such as semiconductor equipment, laser instruments, and medical equipment.

Surface treatment: Mirror polishing (Ra<0.1μm), coating adhesion (metallization treatment) and other processes are provided to meet the friction coefficient and conductivity requirements under different working conditions.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어