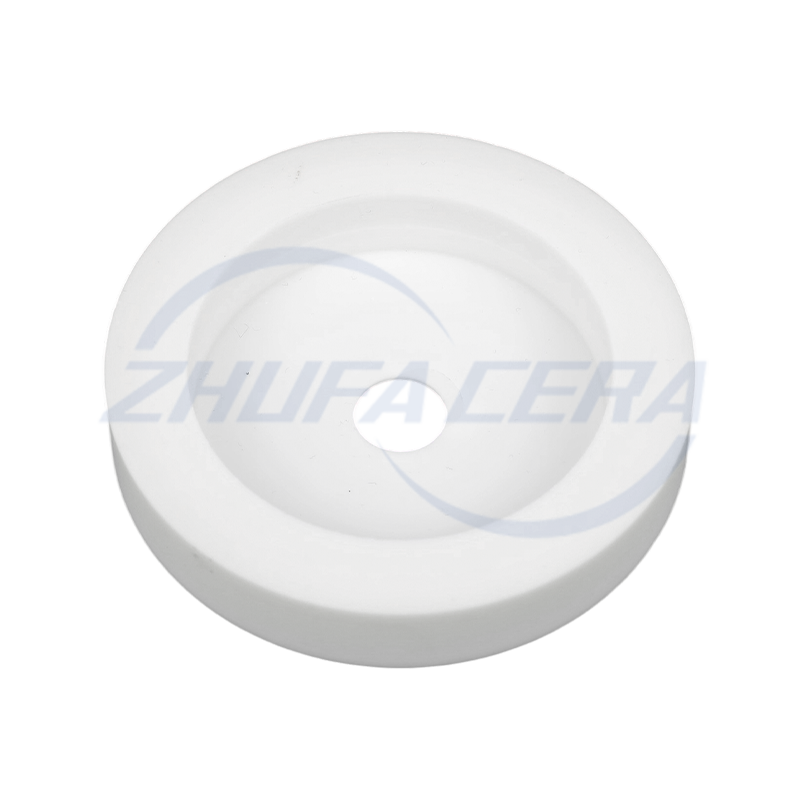

Perforated Alumina Ceramic Disc is a high-performance functional component designed for harsh industrial environments. Compared with ordinary metal or polymer perforated discs, this product has extreme wear resistance, ultra-high temperature stability (withstands 1600°C) and excellent chemical inertness due to its high purity of more than 99% alumina ceramic material, and can maintain structural integrity for a long time in strong acids, strong bases and corrosive gases. Its precision laser drilling technology can achieve micron-level aperture accuracy (±0.05mm) and customized hole layout to ensure efficient and uniform distribution of fluids, gases or particulate media. It is particularly suitable for high-end fields such as semiconductor wafer etching fixtures, high-temperature gas filtration systems and fuel cell electrode support substrates.

Typical application scenarios:

High-temperature gas treatment: molten metal filtration, heat treatment furnace diversion

Precision chemical pharmaceuticals: microporous filters, catalyst carriers

Semiconductor manufacturing: plasma etching wafer carriers, PVD/CVD fixtures

New energy equipment: solid oxide fuel cell bipolar plates, electrolyzer diaphragms

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어