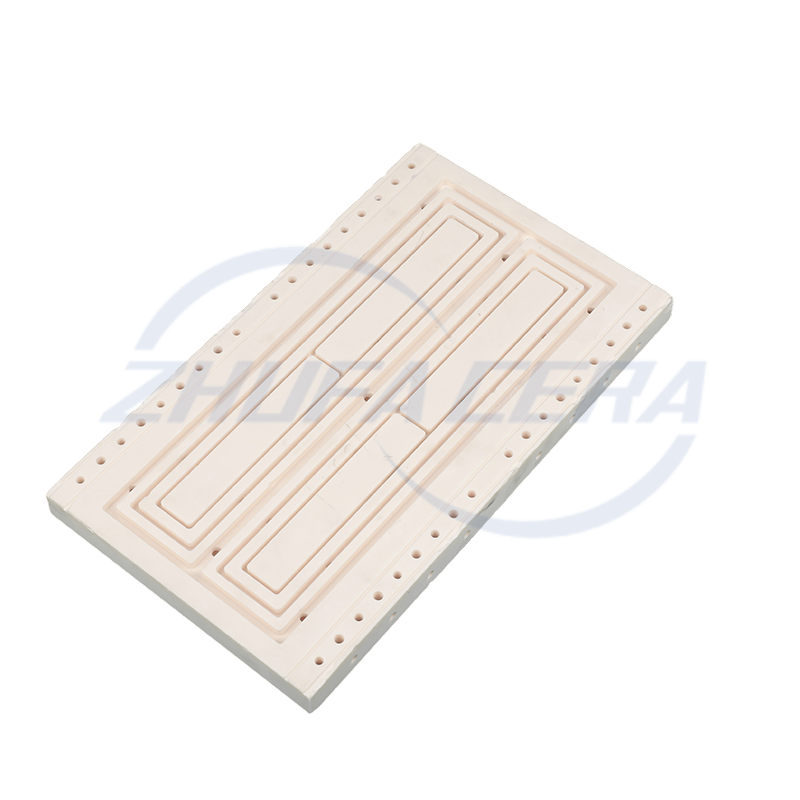

Large-Size Alumina Ceramic Plate is a high-performance ceramic product made of high-purity alumina (Al₂O₃) as the main raw material. Its size usually exceeds the specifications of conventional ceramic plates (such as length or width of more than 500mm). Compared with traditional small-size alumina ceramic plates, this product achieves seamless integration of a larger area by optimizing the molding process and sintering technology, significantly reducing the splicing gap during installation, and improving the stability and aesthetics of the overall structure. Its core advantages lie in high density, high mechanical strength and excellent corrosion resistance. It can withstand high temperatures (up to 1600℃) and strong acid and alkali environments, while maintaining low thermal expansion coefficient and high insulation. It is suitable for industrial scenarios with strict requirements on material performance.

Large-Size Alumina Ceramic Plate is made by dry pressing or isostatic pressing, and is made by high-temperature sintering. The product density can reach 3.8-3.9g/cm³, and the Mohs hardness reaches level 9, second only to diamond. Its large-size design can reduce the number of joints in engineering installation, reduce the risk of liquid or gas leakage, and improve surface flatness (flatness error ≤ 0.1mm). This product is widely used in chemical equipment linings, electronic component substrates, high-temperature furnace linings, and building curtain wall decoration. In the chemical industry, its corrosion resistance can effectively resist the erosion of strong acids, strong alkalis, and organic solvents; in the electronics field, its high insulation and low dielectric constant (ε≈9-10) make it an ideal carrier for high-frequency circuit boards; in the construction field, large-size ceramic panels can achieve anti-slip and self-cleaning functions through special glaze treatment, which is suitable for public spaces such as subway platforms and airport halls. The product supports customized processing, including hole opening, chamfering, polishing and other processes to meet the assembly needs of different scenarios.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어