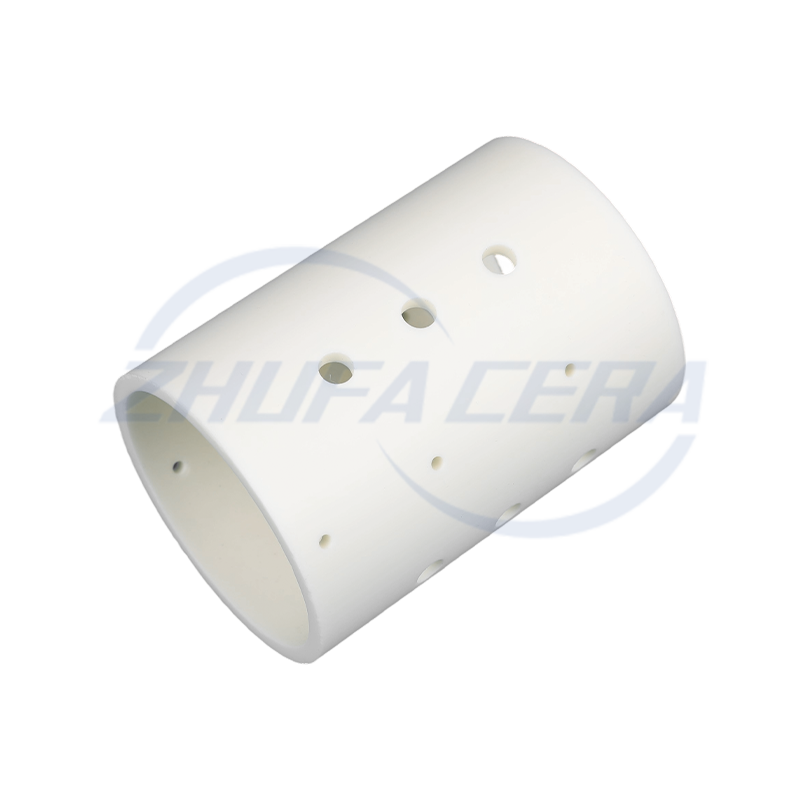

Three-Hole Alumina Ceramic Tube is a precision ceramic tube made of high-purity alumina material. Its core feature is that three parallel through holes are evenly distributed on the tube body. Compared with traditional single-hole or double-hole ceramic tubes, this product has achieved functional expansion and performance optimization in structural design. It not only retains the inherent high strength, high temperature resistance, and good insulation of alumina ceramics, but also improves the heat dissipation efficiency and uniformity of fluid/gas distribution through a porous layout. It is particularly suitable for industrial scenarios that require multi-channel transmission or precise temperature control.

Three-Hole Alumina Ceramic Tube is made of α-Al₂O₃ as the main raw material, and is made by dry pressing and high-temperature sintering. The density is more than 3.8g/cm³, the bending strength exceeds 300MPa, and the operating temperature range covers -50℃ to 1600℃. The three through holes are arranged in an equilateral triangle, the aperture accuracy can reach ±0.05mm, the hole wall thickness is uniform, and the risk of thermal stress concentration is effectively reduced. The surface of the product can be polished or plated to meet the contact requirements of different media. Typical applications include: electronic device packaging, chemical process equipment, high temperature sensors, optical instruments

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어