Zirconia Ceramics Manufacturers

-

Read More

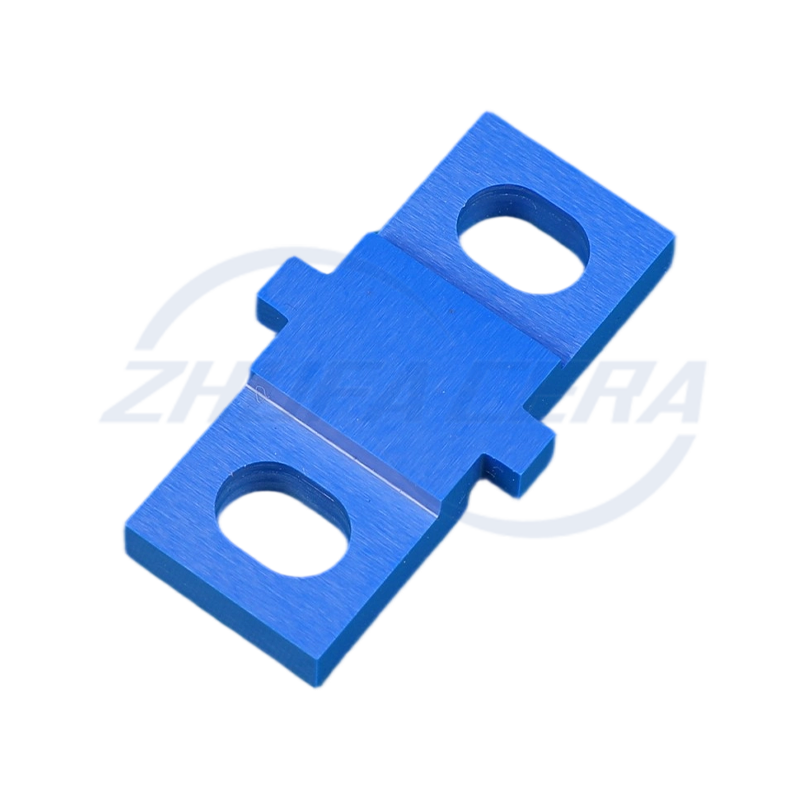

Blue zirconia ceramic positioning block

Blue zirconia ceramic positioning blocks are precision-designed high-performance components designed to cope with demanding industrial and technological applications. They are made of high-purity zirconia ceramics, and use a special additive process to obtain a blue appearance, combining the strength and aesthetics of the material itself. Its Mohs hardness is 8.5-9.1 and its bending strength is between 480 and 1000 MPa, which can resist wear, corrosion and thermal deformation under harsh environments. The low coefficient of thermal expansion ensures micron positioning accuracy under temperature fluctuations, while electrical insulation and non-magnetic properties make it ideal for electronic and optical systems. These positioning blocks are designed for critical positioning tasks in mold manufacturing, robotics and aerospace equipment, and maintain structural integrity under high load operation. The fracture toughness of blue zirconia (6-8 MPa·m¹/²) and thermal stability up to 1000°C ensure their reliable performance in environments such as welding, chemical processing and high-speed processing. Custom features include tight tolerances (roundness ≤ 0.002 mm, surface roughness Ra 0.02-0.2) and complex geometry for seamless integration into precision fixtures and automation systems. Whether used for alignment of components in medical equipment or stabilization of industrial machinery, these positioning blocks redefine durability and accuracy in ceramic engineering.

-

Read More

Pagoda-Shaped Zirconia Ceramic Bushing

Pagoda-Shaped Zirconia Ceramic Bushing is a high-performance industrial component made of advanced zirconia ceramic material, widely recognized for its excellent mechanical properties and structural integrity. It is precision machined to form a unique pagoda-shaped profile, which is composed of multiple layers of tapered structures, which can effectively increase load-bearing capacity and reduce stress concentration in dynamic environments. The zirconia ceramic used to make this bushing has high hardness (Mohs hardness can reach level 9), compressive strength of more than 2000MPa, and thermal stability up to 250°C, which can maintain stable performance under extreme conditions such as high pressure, abrasion and chemical corrosion. At the same time, its smooth surface treatment and precise dimensional control further optimize fluid dynamics and reduce friction, which is very suitable for applications that require both structural support and operational efficiency. Designed with versatility in mind, Pagoda-Shaped Zirconia Ceramic Bushing has important applications in many industries such as chemical, oil and gas extraction and precision machinery. In high-pressure pump systems, its corrosion resistance can resist the erosion of corrosive fluids while maintaining tight sealing performance. In the automotive and aerospace sectors, the bushing’s low thermal conductivity (1.6–2.03 W/(m・K)) and thermal shock resistance ensure reliable operation in engines and turbines subject to rapid temperature fluctuations. In addition, due to its biocompatibility and chemical inertness, it is also suitable for medical devices that require sterile, non-toxic parts. By combining the pagoda-shaped structure with the toughness and wear resistance of zirconium oxide itself, the bushing can extend service life, reduce maintenance costs, and perform well in harsh industrial environments.

-

Read More

Blue zirconia ceramic sheet

Blue zirconia ceramic sheets are precision components made of advanced zirconia ceramics. They are stained with cobalt, iron or copper to form a blue color. This color not only serves as a visual identifier, but also ensures uniform absorption and reflection of light, making it an ideal choice for applications requiring optical accuracy. The material undergoes rigorous manufacturing process, including nano-scale powder dispersion (particle size As a multi-purpose design, blue zirconia ceramic sheets have been widely used in key industries. In the field of fiber, its bright blue color helps accurately align the fiber's position in the V-shaped groove, improving signal transmission efficiency by reducing light reflection (average reduction of 15%). In the medical field, thanks to its biocompatibility and aesthetic appeal, it is widely used in dental restorations such as crowns and implant abutments, as well as orthopedic implants, ensuring long-term durability and tissue compatibility. Industrial applications include high-speed machining tools, whose hardness and thermal stability can withstand high pressures and are suitable for semiconductor devices requiring corrosion-resistant components. In addition, its electrical insulation properties (dielectric strength 13 KV/mm) make it suitable for electronic devices that require reliable isolation in high-frequency environments. Dimensional accuracy can be achieved through CNC machining and surface treatments can range from matte to mirror polishing, providing customized solutions for functional and decorative applications in a variety of technical fields.

-

Read More

Zirconia Ceramic Bushing

Zirconia Ceramic Bushing is a critical engineering component precision-made from high-performance zirconium oxide (ZrO₂) ceramic material. It is known for its excellent mechanical and physical properties, including extremely high hardness (typically over 1200 HV), excellent wear resistance, and excellent fracture toughness (due to the phase transformation toughening mechanism of zirconium oxide). The bushing has an extremely low coefficient of thermal expansion, ensuring that it maintains dimensional stability over a wide temperature range, and has excellent chemical corrosion resistance, and can resist corrosion from a variety of acids, bases and organic solvents. Its inherent electrical insulation properties also make it essential in applications that require electrical isolation. These combined properties make it a reliable and long-lasting solution for critical locations that are subject to severe mechanical stress, friction and wear or corrosive environments. In specific applications, Zirconia Ceramic Bushing is often designed to replace traditional metal or polymer bushings to significantly improve equipment performance and life. Its ultra-low coefficient of friction (especially when rubbing against metal) can effectively reduce energy loss during power transmission and reduce wear. Its excellent high-temperature resistance allows it to work stably in environments where metal or plastic materials fail. Whether in high-speed rotating equipment (such as pumps, motors, spindles), linear motion systems subjected to heavy loads or impact loads, chemical equipment in highly corrosive media, or semiconductor manufacturing and biomedical fields that require high cleanliness and non-magnetic environments, this ceramic bushing can provide excellent support, guidance, positioning and isolation functions, and is an ideal choice for those pursuing high reliability, long life and low maintenance costs.

-

Read More

Blue Zirconia Ceramic Pin

This blue zirconia ceramic pin is made of advanced zirconia ceramic material, providing excellent durability and performance. Zirconia ceramics are known for their high strength, good wear resistance and reliable hardness, making them stronger than many metals or traditional ceramics. This inherent toughness allows the pins to withstand severe mechanical stresses, harsh environments and contact with corrosive substances without deterioration. Its inherent stability also ensures less friction and stable performance over long-term use. In addition to its functional characteristics, this zirconia ceramic pin also has a special blue appearance. This bright color not only provides obvious visual recognition for components or applications, but also adds a charm to modern industrial aesthetics. Blue is usually an inherent feature of zirconia material, and is achieved through a specific process to ensure that the color lasts for a long time and does not fade. Combining high-performance ceramic engineering with beautiful visual effects makes it a reliable and easy-to-identify component in precision applications.

-

Read More

Zirconia Ceramic Guide Rail

Zirconia Ceramic Guide Rail is a high-performance precision mechanical component made of zirconium oxide ceramic material. Its core characteristics are derived from the excellent physical and chemical properties of zirconium oxide ceramic. The product has extremely high hardness (Mohs hardness 8.5-9.1) and bending strength (400-1000MPa), which is significantly better than traditional metal guide rails. It can withstand high-intensity mechanical loads and maintain long-term structural stability. Its surface is precisely polished, and the friction coefficient is as low as 1/2-1/3 of alumina ceramics. With micron-level processing accuracy (such as ±0.008mm/300mm molding accuracy), it can achieve ultra-precision linear motion and effectively reduce equipment operation noise and energy consumption. In addition, the guide rail has excellent corrosion resistance and high temperature resistance (long-term working temperature can reach 1000℃), and can still maintain stable operation in acid and alkali environments, high humidity or extreme temperature conditions. At the same time, its low thermal expansion coefficient (9.6×10⁻⁶/℃) is close to that of steel, which can avoid deformation caused by thermal stress. As an insulating material, it can also effectively block electromagnetic interference and is suitable for electronic equipment environments that are sensitive to static electricity. In industrial applications, Zirconia Ceramic Guide Rail is mainly used in precision processing equipment, semiconductor manufacturing equipment, medical instruments and automated production lines. Its high precision and wear resistance make it a core component of precision machinery such as optical inspection equipment and electronic component placement machines, ensuring micron-level positioning accuracy and long-term trouble-free operation. In semiconductor wafer processing, the corrosion resistance of the guide rail can resist the erosion of chemical etchants and ensure the reliability of equipment in clean room environments; in the medical field, its biocompatibility (in compliance with ISO 10993 standards) makes it suitable for the motion systems of surgical robots and precision medical instruments, avoiding allergic reactions that may be caused by metal materials. In addition, the guide rail performs well in aseptic filling equipment in the food and beverage industry, and its non-conductive and self-lubricating properties prevent contamination and reduce maintenance frequency. Compared to traditional metal guide rails, Zirconia Ceramic Guide Rail has a service life that can be extended by 3-5 times, while reducing downtime and maintenance costs caused by wear. It is particularly suitable for high-end manufacturing scenarios that have stringent requirements on precision, corrosion resistance and environmental adaptability.

-

Read More

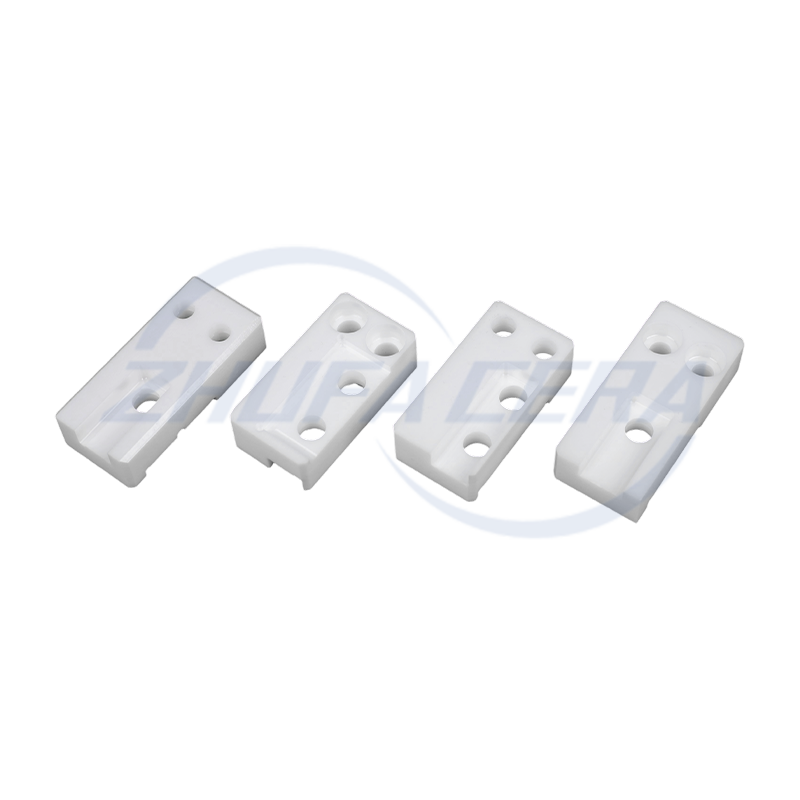

Zirconia Ceramic Positioning Block

As a high-precision industrial component, the Zirconia Ceramic Positioning Block uses high-purity zirconium oxide (ZrO₂) as the core material. It is formed through nano-scale powder preparation and precision sintering process, and has both the toughness of metal and the corrosion resistance of ceramic. Its bending strength reaches 1200-1400 MPa, which is close to the level of some alloy steels. At the same time, it has a unique "phase change toughening" mechanism, which can maintain fracture resistance under cyclic loads and ensure long-term stability. The surface hardness of the product reaches Hv 1200-1400, and the wear resistance is more than 15 times that of traditional metals. With a low thermal expansion coefficient (10.5×10⁻⁶/K), it can withstand extreme temperature differences without deformation. In addition, its biocompatibility has been certified by ISO 10993, it is resistant to corrosion by acids, alkalis, salts and organic solvents, and its resistivity exceeds 10¹⁴ Ω·cm, making it suitable for high temperature and high voltage insulation scenarios. Through CNC processing and laser cutting technology, the positioning block can achieve ±0.01 mm tolerance control, support customized structural design and color aesthetic processing, and meet diversified application needs. Zirconia Ceramic Positioning Block is widely used in precision machinery, semiconductor manufacturing, medical equipment and aerospace. In the semiconductor industry, as a wafer polishing fixture, it can avoid metal contamination during processing and improve chip yield with its zero magnetic interference and high hardness characteristics; in the medical field, its biological inertness makes it an ideal material for implants such as artificial joint ball heads and implant bases, with a wear resistance life of more than 20 years. In industrial scenarios, as a core component of fiber optic connectors, bearing seals and high-temperature nozzles, the positioning block can maintain stable mechanical properties under long-term use at 2400°C, significantly reducing the frequency of equipment maintenance. Its lightweight design (density 6.05 g/cm³, only 1/3 of steel) effectively reduces energy consumption, while its thermal shock resistance (temperature difference resistance 250°C) makes it the first choice for protection in ultra-high temperature environments such as molten metal crucibles and rocket nozzles. By replacing traditional metal and plastic components, this product can extend the equipment life cycle by 30%-50%, with significant overall cost advantages.

-

Read More

Zirconia Ceramic Locating Pin

Zirconia Ceramic Locating Pin is a high-precision positioning element made of advanced zirconium oxide ceramic material with excellent physical and chemical properties. Its main characteristics include extremely high Vickers hardness (usually over 1200 HV), excellent wear resistance and impact resistance, and can effectively resist chemical corrosion, high temperature (operating temperature can reach over 1000°C) and electrical insulation performance, ensuring long-term stable operation in harsh environments. The role of this product is to provide precise mechanical positioning functions. Through its ultra-low thermal expansion coefficient and high dimensional stability, it can achieve precise alignment between components and reduce assembly tolerances, thereby improving manufacturing accuracy and system reliability. In addition, its non-magnetic properties avoid electromagnetic interference problems and are suitable for sensitive electronic devices. This product is widely used in precision engineering fields such as automated assembly lines, mold manufacturing, semiconductor packaging, and medical device production. In applications, Zirconia Ceramic Locating Pin can optimize production processes and reduce maintenance costs; its chemical inertness and biocompatibility make it play a key role in food processing or clean room environments to prevent contamination risks. By reducing friction loss and extending service life, it significantly improves the overall efficiency and safety of equipment, becoming an indispensable high-performance positioning solution in modern industry.

-

Read More

Zirconia Ceramic Valve Sleeve

Zirconia Ceramic Valve Sleeve is made of advanced zirconium oxide ceramic material, with excellent mechanical properties and chemical stability. Its core advantage lies in the coexistence of high strength and high toughness. Through the unique crystal phase structure design, it can effectively disperse stress and avoid brittle fracture when subjected to impact or alternating loads. It is especially suitable for high-pressure, high-frequency opening and closing valve conditions. The surface of this material is dense and non-porous, with excellent wear and corrosion resistance. Even if it is exposed to strong acids, strong alkalis or media containing solid particles for a long time, it can maintain structural integrity and dimensional accuracy, significantly extending the overall service life of the valve. In addition, its low friction coefficient and self-lubrication can reduce energy loss between moving parts and reduce operating torque. At the same time, its high insulation performance makes it unique in electronic control valves. As the core sealing and guiding element of the valve system, Zirconia Ceramic Valve Sleeve achieves micron-level coaxiality and surface finish through precision machining, ensuring smooth movement of the valve core without stagnation and effectively preventing medium leakage. In industrial processes, this product is widely used in harsh environments such as oil extraction, chemical reactors, and seawater desalination. After replacing traditional metal valve sleeves, it can greatly reduce the frequency of downtime maintenance caused by corrosion or wear; in the field of clean energy, its high temperature resistance (short-term tolerance temperature exceeds 2000°C) makes it a key component of solar thermal power generation and nuclear energy equipment heat exchange systems; in medical equipment, its biological inertness is used to develop sterile fluid control valves to meet the delivery needs of high-purity liquid medicines or biological agents. Its lightweight design also provides a solution for weight reduction and efficiency improvement in the aerospace field, making it an ideal material for satellite propulsion systems and rocket engine valve components.

-

Read More

Zirconia Ceramic Valve Core

Zirconia Ceramic Valve Core exhibits excellent comprehensive performance. It is based on high-quality zirconium oxide ceramics, has extremely high hardness and strength, and has significantly better wear resistance than traditional metal materials. It can maintain a precise structure in long-term high-frequency opening and closing operations, effectively reducing performance degradation caused by wear. At the same time, the valve core has excellent corrosion resistance, excellent resistance to various chemical media such as acids, alkalis, organic solvents, and outstanding high-temperature resistance. It can maintain stable mechanical properties in a wide temperature range, has good chemical stability, and is not easy to react with the contacting fluid, ensuring the purity of the fluid medium is not contaminated. Zirconia Ceramic Valve Core plays a key role in fluid control systems. As the core component of the valve, it achieves precise control of the fluid on-off state and fine adjustment of the flow rate through precise cooperation with the valve seat, ensuring the stability and controllability of the fluid transmission process. With its excellent properties, this valve core is widely used in chemical, pharmaceutical, food processing, semiconductor manufacturing and other fields. It is especially suitable for conveying corrosive media, high-temperature fluids or fluid systems with extremely high cleanliness requirements, such as corrosive raw material conveying pipeline valves in chemical production, aseptic fluid control systems in the pharmaceutical industry, and beverage or sauce conveying valves in food processing, etc., providing reliable guarantee for fluid control under various harsh working conditions.

-

Read More

Zirconia Ceramic Valve Core with Metal Threaded Rod

Zirconia Ceramic Valve Core with Metal Threaded Rod has excellent comprehensive performance. The core valve core is made of zirconium oxide ceramic material, which has extremely high hardness and excellent wear resistance. It can effectively resist the loss caused by long-term fluid erosion and extend the service life. At the same time, zirconium oxide ceramic also has excellent corrosion resistance and high temperature resistance, which can adapt to the working requirements of various acid and alkali media and high temperature environments. The metal threaded rod ensures the stability of the connection between the valve core and other parts of the valve with high strength and good mechanical properties, and provides reliable support for the precise movement of the valve core. In the valve system, it achieves precise control of fluid on-off and flow rate through precise cooperation with the valve seat, ensuring the stability and efficiency of the fluid delivery process. With these excellent characteristics, Zirconia Ceramic Valve Core with Metal Threaded Rod is widely used in many fields. In the chemical industry, it can be used to control the delivery of various corrosive liquids or gases and withstand the erosion of complex media; in the water treatment field, it can resist the wear of impurities in the water body and ensure the accuracy of water channel regulation; in the medical device field, its high-precision control performance meets the strict requirements of medical fluid delivery; in addition, in food processing, energy delivery and other scenarios that have high requirements on valve performance, this product can also play an important role and provide strong support for the stable operation of related equipment.

-

Read More

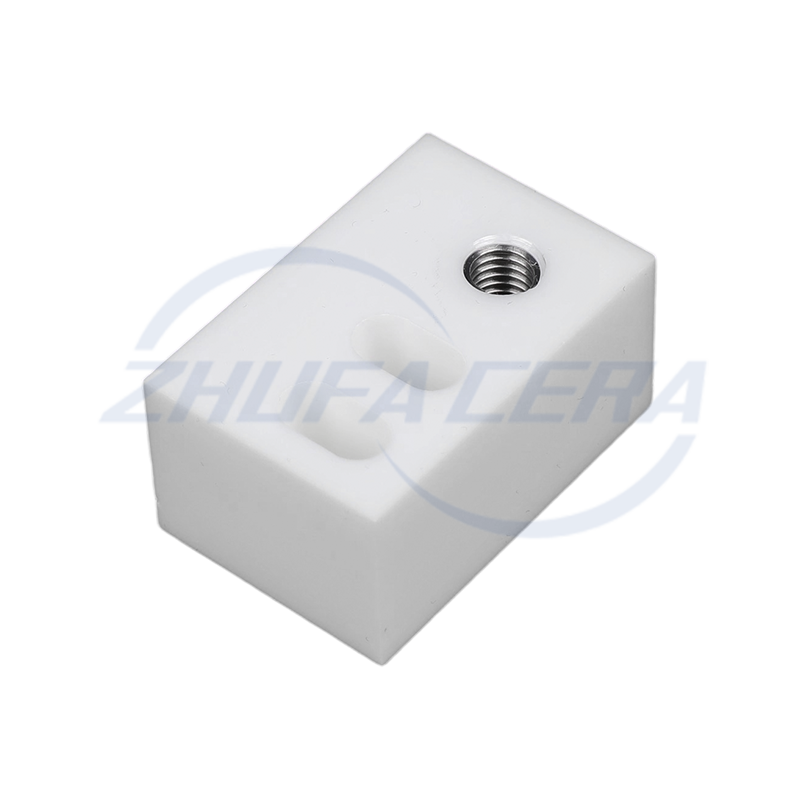

Zirconia Ceramic Positioning Block with Metal Threaded Lining

Zirconia Ceramic Positioning Block with Metal Threaded Lining is a composite positioning component with high-purity zirconium oxide ceramic as the core and metal threaded embedding technology. Its ceramic matrix is formed by advanced sintering process, with high hardness, wear resistance and excellent chemical stability. It can withstand high temperature, strong corrosion and high-frequency friction environment for a long time without performance degradation; the metal threaded bushing is embedded in the ceramic through precision machining and thermal assembly process to form a rigid connection structure, which not only retains the lightweight (density is only 1/3 of steel) and insulation properties of ceramics, but also gives it reliable mechanical connection and impact resistance. The positioning block achieves a balance of wear resistance, thermal stability and structural strength through the synergy of ceramics and metals, and is suitable for industrial scenarios with strict requirements on the comprehensive performance of materials. Zirconia Ceramic Positioning Block with Metal Threaded Lining is mainly used in the fields of high-precision positioning and wear protection. In semiconductor manufacturing, it is a key positioning component of the wafer transfer system, which can withstand the highly corrosive gas and high-frequency mechanical friction in the plasma cleaning process to ensure the long-term operation accuracy of the equipment; in the aerospace field, this component is used for the guidance and positioning of the hot end components of the engine. With the ultra-high temperature resistance of ceramics and the thermal shock resistance of metal threads, it can adapt to stable operation in extreme temperature difference environments; in precision processing and automation equipment, it is used as the positioning base of CNC machine tool spindles and robot joints, and realizes micron-level motion control through the high rigidity of ceramics and the reliability of metal connections. In addition, this product is also widely used in chemical machinery (corrosion-resistant valve positioning), new energy equipment (fuel cell component support) and medical instruments (surgical instrument wear-resistant guide) and other fields, meeting the multiple needs of different industries for material durability, precision retention and environmental adaptability.

Zirconia ceramics are advanced engineering ceramic made from high-purity zirconium dioxide. It has become the core material choice in many high-end fields with its excellent comprehensive performance. The most significant advantage of this type of material is its excellent mechanical properties: it has the highest fracture toughness and bending strength among oxide ceramics, and can withstand severe mechanical shock and high loads; at the same time, it has extreme wear resistance and low friction coefficient, which greatly improves the service life of key moving parts. Excellent biocompatibility and chemical inertness make zirconia ceramics an ideal choice for medical implants (such as artificial joint ball heads) and dental restorations (such as all-ceramic crowns and implant bases). In addition, it also has good high-temperature stability, low thermal conductivity and excellent corrosion resistance, and can adapt to complex and harsh industrial environments. Therefore, zirconia ceramics are widely used in precision medical devices, high-performance industrial parts (such as wear-resistant seals, bearings, valves, cutting tools), high-end consumer products (such as watch cases, knives) and electronic components, and are a reliable solution for engineers and designers to solve material performance challenges.

-

The Influence of Zirconia Content on the Performance of ZTA Ceramics Zirconia Toughened Alumina (ZTA) ceramics are widely used in industries where superior mechanical strength and thermal stability are critical. The combination of zirconia (ZrO2) and alumina (Al2O3) results in a material with enhanced toughness, making

READ MORE -

Zirconia Toughened Alumina (ZTA) ceramics are a composite material that combines the properties of zirconia (ZrO2) and alumina (Al2O3). This combination results in a material with superior mechanical properties, such as high fracture toughness and resistance to wear. ZTA ceramics are widely used in industries such as a

READ MORE

-

Black silicon carbide ceramic ring is a high-performance engineered ceramic assembly made

See Details -

Zirconia Ceramic Rod is a high-performance ceramic material rod, mainly made of zirconium

See Details -

Blue zirconia ceramic sheets are precision components made of advanced zirconia ceramic

See Details -

This blue zirconia ceramic pin is made of advanced zirconia ceramic material, providing

See Details -

Zirconia Ceramic Gear is made of zirconium oxide ceramic material, which has excellent hig

See Details -

Zirconia Ceramic Guide Rail is a high-performance precision mechanical component made of z

See Details

Zirconia Ceramics: Manufacturing Insights into Advanced Ceramic Materials

1. Core Properties of Zirconia Ceramics: The "Ceramic Steel" Foundation

Zirconia ceramics stand out as a flagship material in the advanced ceramics sector, earning the title of "ceramic steel" due to their unique combination of strength and toughness that transcends traditional brittle ceramic limitations . At room temperature, they exhibit the highest strength and fracture toughness among all advanced ceramic materials, with bending strength reaching 1200-1400 MPa—surpassing alumina ceramics and approaching some alloy steels . This performance stems from their phase transformation mechanism: pure zirconia exists in monoclinic, tetragonal, and cubic crystal phases at different temperatures, and adding stabilizers like yttria or ceria controls these structural changes to achieve enhanced toughness .

Complementing this mechanical resilience are exceptional functional properties: a melting point of 2700°C enabling long-term use at up to 2400°C, surface hardness of Hv 1200-1400 (15 times more wear-resistant than traditional metals), strong chemical inertness against acids and alkalis, and high electrical insulation with resistivity exceeding 10¹⁴ Ω·cm . These characteristics make zirconia ceramics indispensable across high-demand industrial fields.

2. Key Manufacturing Processes: Precision from Powder to Component

The manufacturing of zirconia ceramics is a highly controlled sequence spanning powder preparation, forming, sintering, and precision finishing—each step critical to final performance.

Powder Preparation: The Starting Point of Quality

High-performance zirconia ceramics require ultra-pure, uniformly dispersed powders with narrow particle size distribution . Common synthesis methods include co-precipitation, hydrothermal synthesis, and sol-gel processes, which produce powders that directly influence sintered density and mechanical strength. Industry standards typically demand powder purity above 99.9% to avoid impurity-induced performance degradation . Manufacturers like Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. integrate raw material processing into their end-to-end production workflow, laying the groundwork for consistent component quality .

Forming: Shaping for Diverse Requirements

Forming processes are selected based on component geometry and production volume:

Dry Pressing & Cold Isostatic Pressing: Ideal for relatively simple shapes, these methods ensure uniform density. Cold isostatic pressing enhances green body consistency, a technique employed by facilities equipped with advanced pressing equipment .

Injection Molding: Suited for complex, high-precision parts and large-scale production, it delivers exceptional dimensional accuracy despite requiring specialized tooling .

Laser Cutting: Used for thin substrates (typically ≤1mm thickness), widely applied in electronic components manufacturing .

Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. has built its 30,000㎡ manufacturing base with a full suite of forming equipment—including dry pressing, cold isostatic pressing, and injection molding systems—to accommodate both standard and custom requirements .

Sintering: Achieving Densification and Performance

Sintering transforms green bodies into dense ceramic components, with temperature control being paramount. Most manufacturers utilize high-temperature sintering furnaces for pressureless sintering, the dominant method in the industry . Advanced techniques like hot isostatic pressing (HIP) or spark plasma sintering (SPS) can further improve density and reduce porosity, critical for applications in harsh environments . Strict sintering process control ensures the final product maintains thermal stability and corrosion resistance.

Precision Finishing: Meeting Micron-Level Tolerances

Post-sintering processing is essential for achieving industrial precision requirements. CNC engraving machines, surface grinders, and honing machines are employed to refine dimensions and surface quality, with leading manufacturers achieving tolerances of ±0.01mm . Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. equips its production base with such precision machining tools, supporting non-standard processing and small-batch proofing for diverse industrial needs .

3. Industrial Applications: Driving Innovation Across Sectors

Zirconia ceramics' versatility enables their adoption in strategic emerging industries, aligning with the global advanced ceramics market's shift toward high-value applications .

Automotive & New Energy

In automotive systems—including engines, sensors, fuel cells, and braking systems—zirconia ceramics enhance performance and durability through their wear resistance, high-temperature stability, and insulation . They play a key role in advancing new energy and smart vehicles, where reliability under extreme conditions is critical .

Semiconductor & Electronics

High-purity zirconia components are used in wafer handling, etching, and deposition equipment, ensuring process accuracy while reducing contamination risks . Their non-magnetic properties and thermal stability make them ideal for semiconductor manufacturing, supporting the industry's localization drive .

Petrochemical & Photovoltaics

In petrochemical pumps, valves, and reactors, zirconia's corrosion and wear resistance reduces maintenance costs and extends equipment life . In photovoltaic manufacturing, it withstands the high temperatures of wafer sintering processes, boosting production efficiency .

Medical & Beyond

Biocompatible zirconia variants are widely used in dental crowns and orthopedic implants, meeting ISO 10993 standards for human safety . This medical application segment represents one of the fastest-growing areas for advanced ceramics .

-

Quick Links

Home Products About Us Services Technology News Contact Us -

Products

Ceramic Structural Parts Zirconia Ceramics Alumina Ceramics ZTA Ceramics Silicon Nitride Ceramics Silicon Carbide Ceramics Ceramic Injection Molded Parts -

About Us

Factory Tour Honor FAQ -

Contact info

+86-188 8878 5188zf@zfcera.comNo. 1, Xinggong Road, Anchang Industrial Park, Keqiao District, Shaoxing City, Zhejiang Province, China -

Qrcode

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어