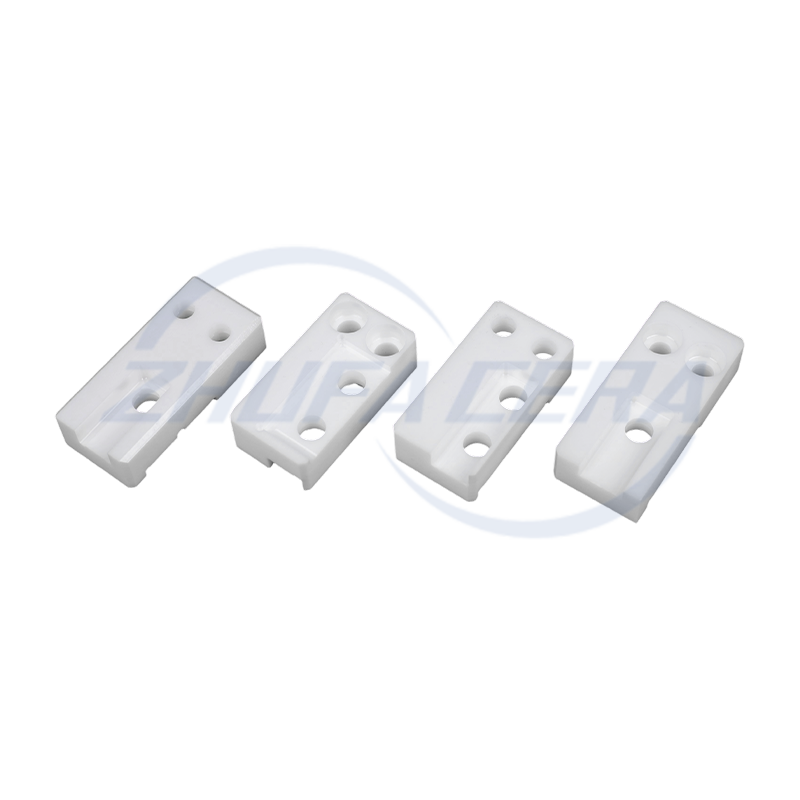

As a high-precision industrial component, the Zirconia Ceramic Positioning Block uses high-purity zirconium oxide (ZrO₂) as the core material. It is formed through nano-scale powder preparation and precision sintering process, and has both the toughness of metal and the corrosion resistance of ceramic. Its bending strength reaches 1200-1400 MPa, which is close to the level of some alloy steels. At the same time, it has a unique "phase change toughening" mechanism, which can maintain fracture resistance under cyclic loads and ensure long-term stability. The surface hardness of the product reaches Hv 1200-1400, and the wear resistance is more than 15 times that of traditional metals. With a low thermal expansion coefficient (10.5×10⁻⁶/K), it can withstand extreme temperature differences without deformation. In addition, its biocompatibility has been certified by ISO 10993, it is resistant to corrosion by acids, alkalis, salts and organic solvents, and its resistivity exceeds 10¹⁴ Ω·cm, making it suitable for high temperature and high voltage insulation scenarios. Through CNC processing and laser cutting technology, the positioning block can achieve ±0.01 mm tolerance control, support customized structural design and color aesthetic processing, and meet diversified application needs.

Zirconia Ceramic Positioning Block is widely used in precision machinery, semiconductor manufacturing, medical equipment and aerospace. In the semiconductor industry, as a wafer polishing fixture, it can avoid metal contamination during processing and improve chip yield with its zero magnetic interference and high hardness characteristics; in the medical field, its biological inertness makes it an ideal material for implants such as artificial joint ball heads and implant bases, with a wear resistance life of more than 20 years. In industrial scenarios, as a core component of fiber optic connectors, bearing seals and high-temperature nozzles, the positioning block can maintain stable mechanical properties under long-term use at 2400°C, significantly reducing the frequency of equipment maintenance. Its lightweight design (density 6.05 g/cm³, only 1/3 of steel) effectively reduces energy consumption, while its thermal shock resistance (temperature difference resistance 250°C) makes it the first choice for protection in ultra-high temperature environments such as molten metal crucibles and rocket nozzles. By replacing traditional metal and plastic components, this product can extend the equipment life cycle by 30%-50%, with significant overall cost advantages.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어