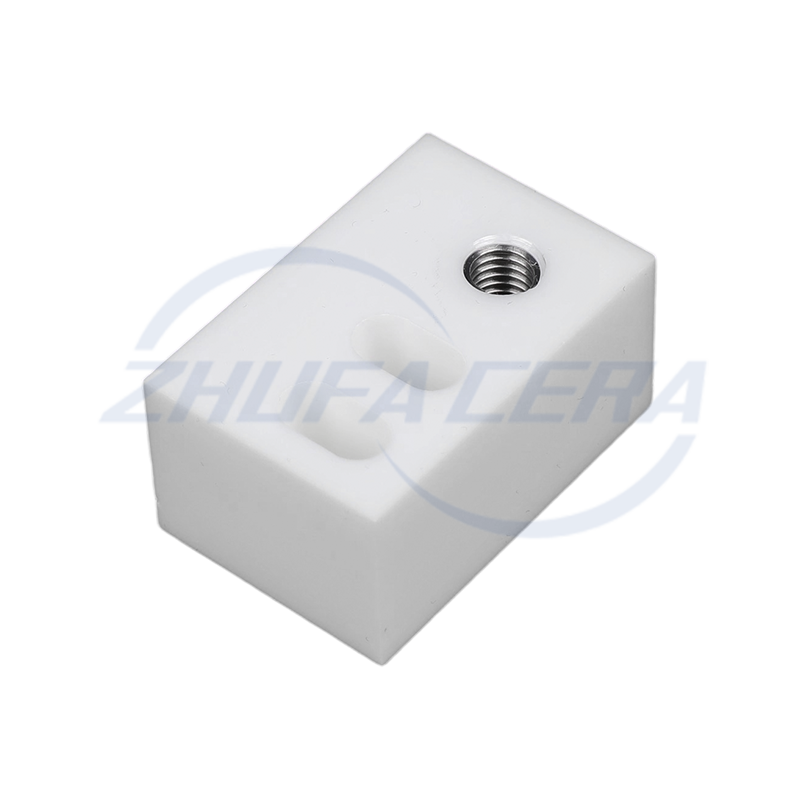

Zirconia Ceramic Positioning Block with Metal Threaded Lining is a composite positioning component with high-purity zirconium oxide ceramic as the core and metal threaded embedding technology. Its ceramic matrix is formed by advanced sintering process, with high hardness, wear resistance and excellent chemical stability. It can withstand high temperature, strong corrosion and high-frequency friction environment for a long time without performance degradation; the metal threaded bushing is embedded in the ceramic through precision machining and thermal assembly process to form a rigid connection structure, which not only retains the lightweight (density is only 1/3 of steel) and insulation properties of ceramics, but also gives it reliable mechanical connection and impact resistance. The positioning block achieves a balance of wear resistance, thermal stability and structural strength through the synergy of ceramics and metals, and is suitable for industrial scenarios with strict requirements on the comprehensive performance of materials.

Zirconia Ceramic Positioning Block with Metal Threaded Lining is mainly used in the fields of high-precision positioning and wear protection. In semiconductor manufacturing, it is a key positioning component of the wafer transfer system, which can withstand the highly corrosive gas and high-frequency mechanical friction in the plasma cleaning process to ensure the long-term operation accuracy of the equipment; in the aerospace field, this component is used for the guidance and positioning of the hot end components of the engine. With the ultra-high temperature resistance of ceramics and the thermal shock resistance of metal threads, it can adapt to stable operation in extreme temperature difference environments; in precision processing and automation equipment, it is used as the positioning base of CNC machine tool spindles and robot joints, and realizes micron-level motion control through the high rigidity of ceramics and the reliability of metal connections. In addition, this product is also widely used in chemical machinery (corrosion-resistant valve positioning), new energy equipment (fuel cell component support) and medical instruments (surgical instrument wear-resistant guide) and other fields, meeting the multiple needs of different industries for material durability, precision retention and environmental adaptability.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어