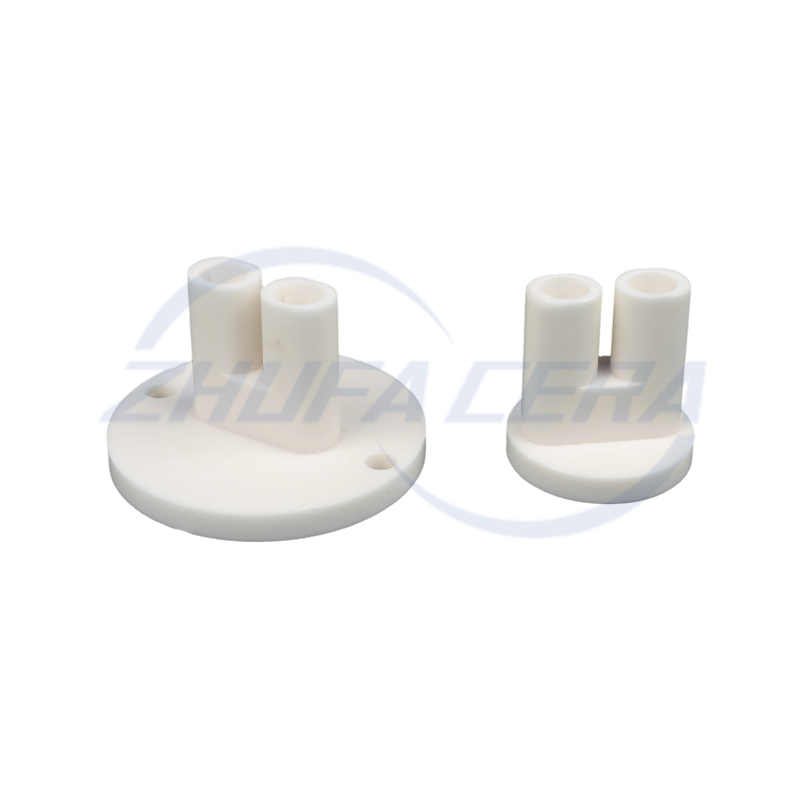

Custom Shape Alumina Ceramic Components are a type of high-performance structural parts in the field of advanced ceramics that are customized according to specific needs. Compared with standardized alumina ceramic products, the core difference is that they can achieve precise molding of complex geometric shapes through precision machining technology, while maintaining the inherent high hardness (HRA ≥ 85), high temperature resistance (operating temperature up to 1600°C), chemical corrosion resistance and excellent electrical insulation properties of alumina ceramics. This type of product is specially developed to solve non-standard design problems in the industrial field, and is particularly suitable for scenarios with strict requirements on material properties and structural adaptability.

Alumina ceramic special-shaped parts combine computer-aided design (CAD) and numerical control machining (CNC) technology to achieve complex shapes from two-dimensional planes to three-dimensional structures, with a minimum machining accuracy of ±0.01mm. The surface finish of the product can reach Ra0.2μm, which effectively reduces friction loss and improves sealing performance. Its material purity (Al₂O₃ content ≥ 95%) ensures dimensional stability for long-term use, and it performs outstandingly in the fields of semiconductor equipment, aerospace propulsion systems, medical implants, etc. Typical applications include:

High-precision sensor base: Thermal stress buffering by using low thermal expansion coefficient (7.2×10⁻⁶/℃)

Plasma-etched chamber lining: High density (3.9g/cm³) to resist chemical erosion

Artificial joint connection parts: Biocompatibility certification (USP Class VI) to meet medical needs

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어