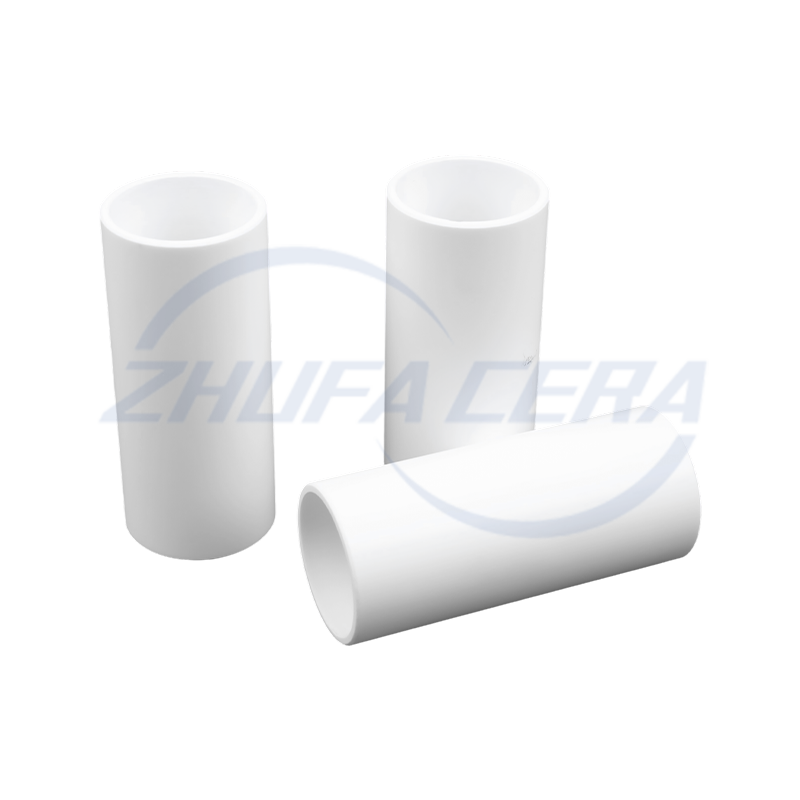

Alumina Ceramic Alumina Tube is a high-performance ceramic tube made of high-purity alumina (Al₂O₃) as the main raw material. It is widely used in industrial scenarios with high temperature, corrosion resistance and high insulation requirements. Compared with similar ceramic tubes (such as silicon nitride or silicon carbide tubes), Alumina Ceramic Alumina Tube achieves a better balance between cost-effectiveness and comprehensive performance. Its core advantages are: high hardness (Mohs hardness level 9), temperature resistance (long-term use temperature can reach 1600℃), chemical corrosion resistance (resistance to acid, alkali and molten metal corrosion) and excellent electrical insulation (volume resistivity>10¹⁴Ω·cm). These characteristics make it an indispensable key material in the fields of electronics, chemical industry, metallurgy and aerospace.

Product Details

Material Characteristics

Alumina Ceramic Alumina Tube uses ≥99% pure alumina raw materials, and is sintered at high temperature (1600-1800℃) to form a dense crystalline structure with low porosity (<1%), ensuring mechanical strength and thermal stability. Its low thermal expansion coefficient (7.2×10⁻⁶/℃) can effectively reduce the risk of deformation under high temperature.

Manufacturing Process

The product achieves precise dimensional control (tolerance ±0.1mm) through dry pressing or isostatic pressing technology, and the surface is ground and polished to a roughness of less than Ra0.2μm, meeting high-precision assembly requirements.

Application Fields

Electronic Industry: As an insulating bushing or high-temperature circuit substrate, it is suitable for power semiconductor packaging and vacuum electronic devices.

Chemical Industry: Used for corrosive fluid delivery pipelines, reactor linings and catalyst carriers.

Medical Equipment: Manufacture of high-temperature sterilization containers and biocompatible components.

Metallurgical industry: used as metal melting crucible or thermocouple protection tube to resist molten metal corrosion.

Environmental protection and durability

The product is lead-free, cadmium-free, RoHS-compliant, and has a service life of more than 10 years, significantly reducing replacement frequency and maintenance costs.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어