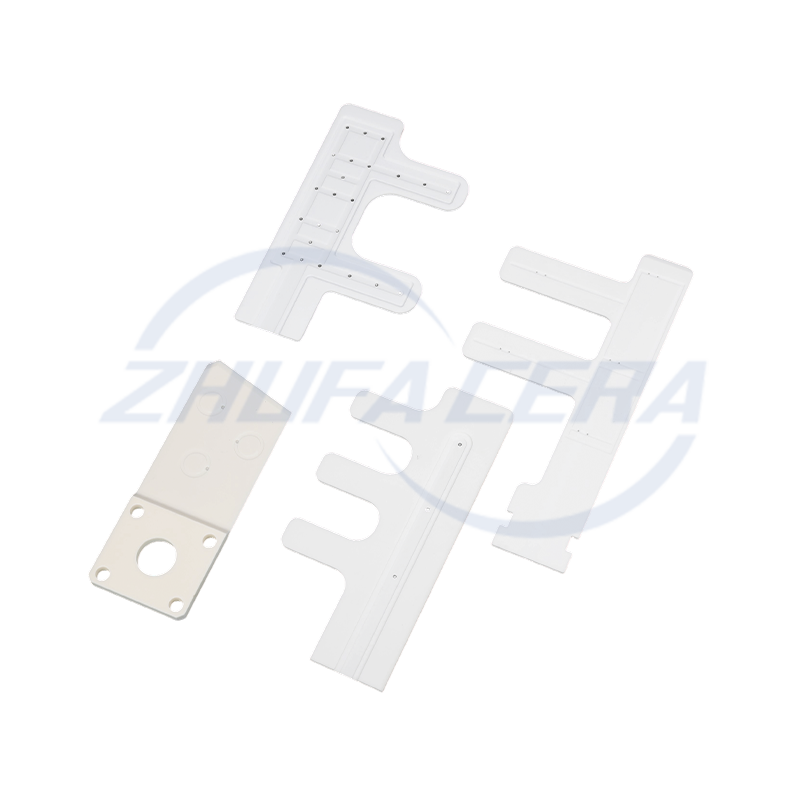

Oxalumina Ceramic Suction Cup Plate is a revolutionary product in the field of precision handling systems. It is made of α-alumina ceramic (α-Al₂O₃) with a purity of ≥99.9%, combined with an engineered porous structure to achieve optimal vacuum distribution. Compared with traditional metal or polymer suction cups, this ceramic solution completely eliminates the risk of particle contamination, while being able to withstand extreme temperatures (1750°C continuous operation) and corrosive environments. Its unique microstructure (2-5μm uniform pore size, 3.89g/cm³ density) ensures submicron flatness (surface roughness Ra≤0.1μm), making it the only professional suction cup platform that can handle 300mm semiconductor wafers with a suction accuracy of ±0.1μm.

1. Breakthrough in material performance

Thermal stability: no deformation in 800°C thermal shock cycles, and a service life 5 times longer than that of alloy suction cups (high temperature process environment).

Chemical resistance: 1-year weight loss of 30% sulfuric acid immersion is less than 0.01g, suitable for battery electrolyte operation and chemical vapor deposition process.

Insulation performance: The breakdown field strength reaches 40kV/mm, ensuring safe operation in the plasma etching chamber.

2. Engineering design innovation

Porosity control: 40% porosity is achieved through gel injection molding process, and the 1-3μm pore wall structure prevents ultra-thin parts (≤50μm) from adsorption and deformation.

Intelligent architecture: Built-in temperature sensor supports real-time thermal management from -196℃ to ultra-high temperature environment.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어