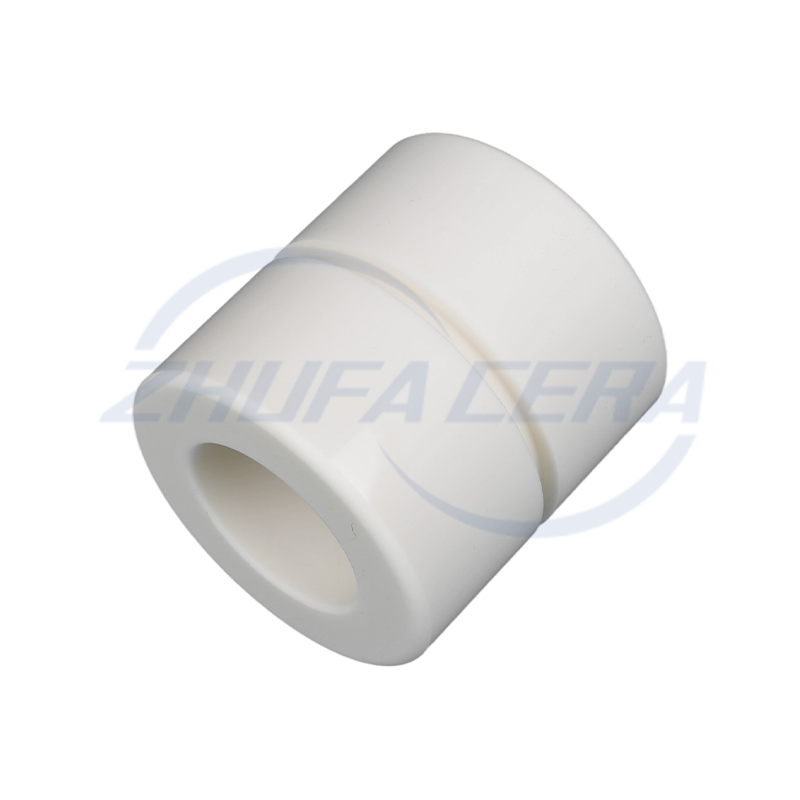

Alumina Ceramic Sleeve is a high-performance ceramic component made of high-purity alumina (Al₂O₃) as the main raw material. It is widely used in electronics, machinery, chemical industry and aerospace fields. Its core advantage is that it can maintain structural stability at extreme temperatures above 1600°C while providing excellent electrical insulation performance. It is an ideal choice for high-temperature sealing, insulation protection and precision mechanical parts. Through the precision sintering process, the product achieves a balance between high density and low porosity, significantly extending its service life, and becoming a key component with both durability and reliability in the industrial field.

Material properties

Alumina ceramic sleeves are made of 95%-99% high-purity alumina raw materials, sintered at high temperature (1600-1800°C), and have the following characteristics:

High temperature resistance and thermal stability: It can withstand a working temperature of 1200°C for a long time and a short-term temperature resistance of 1800°C. It is suitable for scenes such as high-temperature furnaces, heat exchangers and rocket nozzles.

Electrical insulation performance: The volume resistivity is as high as 10¹⁴Ω·cm, which effectively prevents leakage in high-voltage environments and is often used for insulation packaging of semiconductor manufacturing equipment.

Mechanical strength and wear resistance: The bending strength reaches 300-500MPa, and the hardness is close to corundum, which is suitable for high-wear scenarios such as bearings and sealing rings.

Chemical corrosion resistance: Resistant to acid, alkali and organic solvent erosion, suitable for chemical pipeline insulation and corrosive fluid transmission systems.

Manufacturing process

The product achieves high-precision dimensional control (tolerance ±0.01mm) through dry pressing or isostatic pressing technology, combined with surface polishing to ensure close fit with supporting components.

Typical applications

Electronics industry: As an insulating bushing for wafer processing equipment, it ensures the precision of semiconductor manufacturing.

Mechanical engineering: Used for high-temperature pump body seals and valve guide sleeves to reduce friction loss.

Energy field: Provide radiation-resistant and neutron-resistant structural support in nuclear reactors and fuel cells.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어