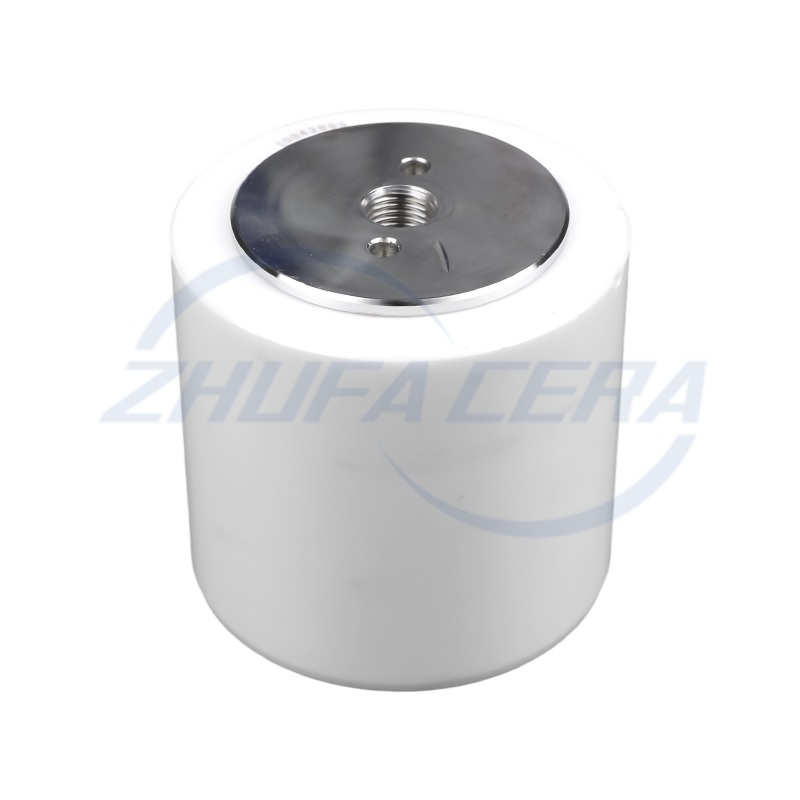

Alumina Ceramic Post Insulator is a rigid insulating component made of high-purity alumina (Al₂O₃ content ≥ 95%). The product has significant advantages due to the inherent characteristics of alumina ceramics: its mechanical strength can reach more than 300MPa, and its bending and compression resistance far exceeds that of organic materials; its dielectric strength (15-20kV/mm) and volume resistivity (10¹⁴–10¹⁵ Ω·cm) ensure insulation reliability in high-voltage environments; it also has extreme temperature tolerance (-60℃ to +500℃), UV aging resistance and chemical corrosion resistance, and is not afraid of harsh environments such as acid rain and salt spray. Alumina ceramic post insulators are widely used in the support insulation of power system disconnectors, circuit breakers, and transformers, as well as electrical isolation of rail transit and new energy equipment, providing long-term and stable solutions for high mechanical loads and harsh working conditions.

Product details and features

Core materials and processes

High-purity alumina matrix: isostatic pressing and high-temperature sintering processes are used to form a dense and uniform corundum structure to ensure material uniformity and low porosity.

Surface glaze treatment: precision glazing enhances surface hydrophobicity, reduces the accumulation rate of dirt, and increases the flashover voltage by more than 20%.

Key performance advantages

Mechanical stability

Flexural strength: ≥300MPa (about 3 times that of ordinary ceramics), can carry large-span busbars or heavy hardware.

Compressive strength: ≥2000MPa, resisting equipment vibration and short-term overload shock.

Electrical reliability

Power frequency withstand voltage: 110kV grade product withstand voltage ≥265kV (dry state)/230kV (wet state).

Lightning impulse withstand voltage: ≥550kV (peak value), effectively suppressing the risk of flashover.

Environmental adaptability

Low thermal expansion coefficient (7-8×10⁻⁶/℃), avoiding stress cracking caused by sudden temperature changes.

Weather resistance: passed 1000 hours salt spray test and QUV ultraviolet aging test, no performance degradation.

Flame retardant grade: A1 (non-combustible material), eliminating fire hazards.

Typical application scenarios

Power system: high-voltage/ultra-high-voltage substation disconnector support, GIS equipment insulation base, lightning arrester support.

Industrial field: arc furnace transformer insulation column, electrolysis equipment high-voltage isolation bracket.

Rail transit: contact network insulation positioning device, traction substation equipment insulation support.

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어