Alumina Ceramics Manufacturers

-

Read More

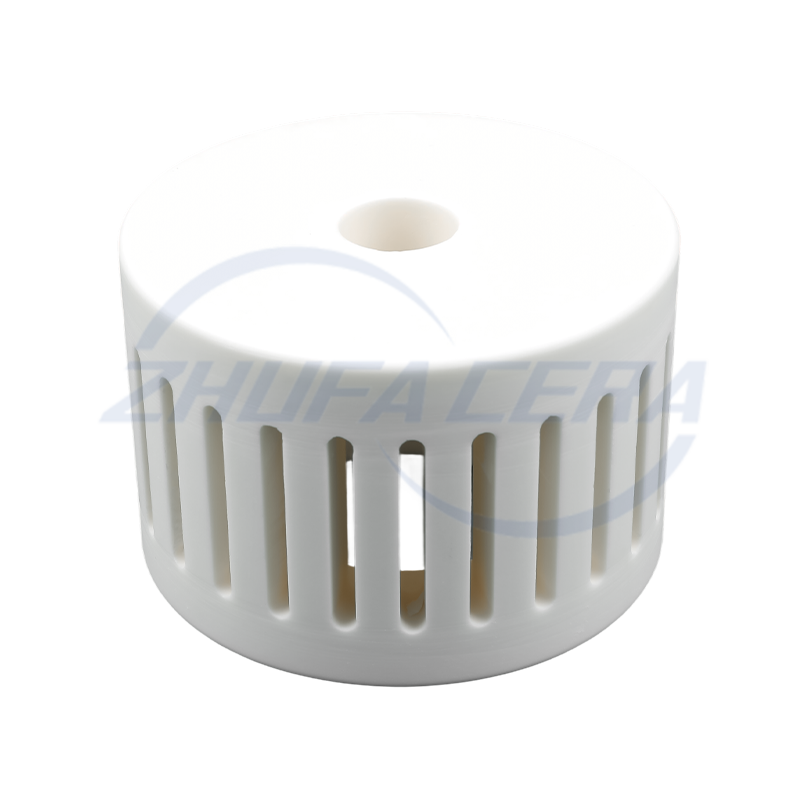

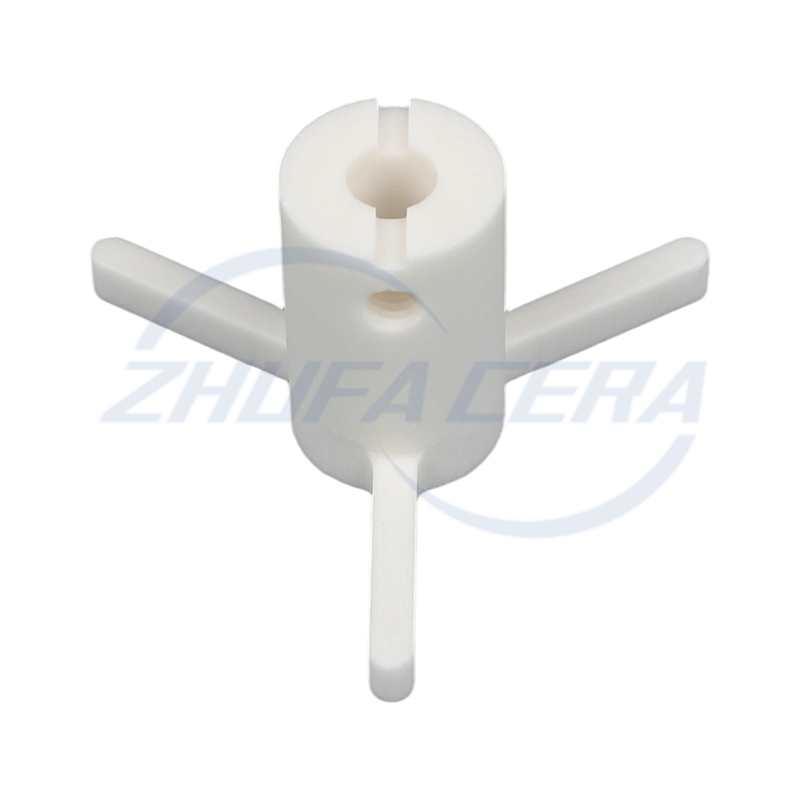

Alumina Ceramic Classifier Wheel

Alumina Ceramic Classifier Wheel is a core precision component used in airflow classifiers and ultrafine powder sorting equipment. Its function is to achieve accurate separation of materials based on the particle size and inertia of the particles. Compared with traditional classifier wheels made of metal or polymer, the core advantage of alumina ceramic classifier wheel lies in the excellent performance of its material itself. It is made of high-purity alumina ceramic sintered by a special process. It has extremely high hardness (Mohs hardness can reach level 9) and excellent wear resistance. It can effectively resist the continuous erosion and wear of powder particles in high-speed airflow, significantly extending the service life of key components. At the same time, the inherent chemical inertness of alumina ceramics gives the product excellent corrosion resistance, enabling it to work stably in acidic, alkaline or other corrosive material environments, while metal wheels are prone to corrosion failure under such conditions. In addition, its low density helps to reduce the inertial load during high-speed rotation. Therefore, the alumina ceramic classifier wheel (Alumina Ceramic Classifier Wheel) shows significant technical advantages in improving classification accuracy, maintaining long-term operating stability, and reducing maintenance frequency and costs caused by wear. Typical application industries: Widely used in fields that require ultrafine powders or strictly control particle size distribution, including but not limited to: Non-metallic mineral powders: Ultrafine grading and purification of calcium carbonate, talc, kaolin, quartz powder, mica powder, silicon micropowder, etc. Advanced ceramics and refractory materials: Fine grading of alumina, zirconium oxide, silicon carbide, silicon nitride powder, etc. New energy materials: Particle size control of lithium battery positive and negative electrode materials (such as lithium cobalt oxide, lithium iron phosphate, ternary materials, graphite), photovoltaic materials, etc. Chemicals and pigments: Grading and depolymerization of fine chemical products, dyes, pigments (such as titanium dioxide). Biomedicine: Ultrafine processing of pharmaceutical raw materials and excipients (must meet relevant cleanliness and inertness requirements). Metal powders: Grading of spherical aluminum powder, copper powder, etc. New materials: Phosphors, catalysts, electronic material powders, etc.

-

Read More

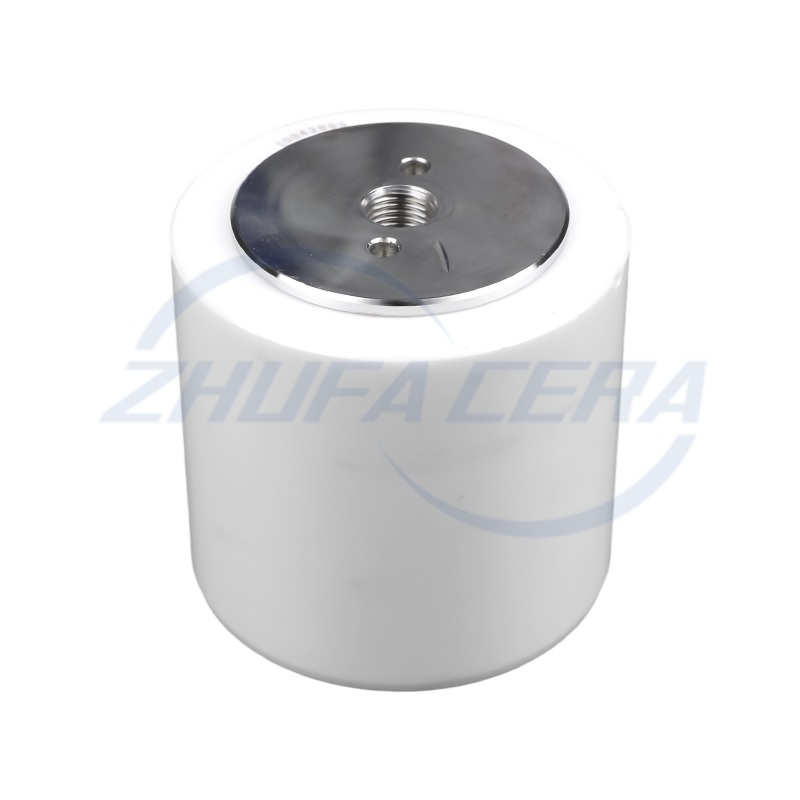

Alumina Ceramic Post Insulator

Alumina Ceramic Post Insulator is a rigid insulating component made of high-purity alumina (Al₂O₃ content ≥ 95%). The product has significant advantages due to the inherent characteristics of alumina ceramics: its mechanical strength can reach more than 300MPa, and its bending and compression resistance far exceeds that of organic materials; its dielectric strength (15-20kV/mm) and volume resistivity (10¹⁴–10¹⁵ Ω·cm) ensure insulation reliability in high-voltage environments; it also has extreme temperature tolerance (-60℃ to +500℃), UV aging resistance and chemical corrosion resistance, and is not afraid of harsh environments such as acid rain and salt spray. Alumina ceramic post insulators are widely used in the support insulation of power system disconnectors, circuit breakers, and transformers, as well as electrical isolation of rail transit and new energy equipment, providing long-term and stable solutions for high mechanical loads and harsh working conditions. Product details and featuresCore materials and processesHigh-purity alumina matrix: isostatic pressing and high-temperature sintering processes are used to form a dense and uniform corundum structure to ensure material uniformity and low porosity.Surface glaze treatment: precision glazing enhances surface hydrophobicity, reduces the accumulation rate of dirt, and increases the flashover voltage by more than 20%.Key performance advantagesMechanical stabilityFlexural strength: ≥300MPa (about 3 times that of ordinary ceramics), can carry large-span busbars or heavy hardware.Compressive strength: ≥2000MPa, resisting equipment vibration and short-term overload shock.Electrical reliabilityPower frequency withstand voltage: 110kV grade product withstand voltage ≥265kV (dry state)/230kV (wet state).Lightning impulse withstand voltage: ≥550kV (peak value), effectively suppressing the risk of flashover.Environmental adaptabilityLow thermal expansion coefficient (7-8×10⁻⁶/℃), avoiding stress cracking caused by sudden temperature changes.Weather resistance: passed 1000 hours salt spray test and QUV ultraviolet aging test, no performance degradation.Flame retardant grade: A1 (non-combustible material), eliminating fire hazards. Typical application scenariosPower system: high-voltage/ultra-high-voltage substation disconnector support, GIS equipment insulation base, lightning arrester support. Industrial field: arc furnace transformer insulation column, electrolysis equipment high-voltage isolation bracket. Rail transit: contact network insulation positioning device, traction substation equipment insulation support.

-

Read More

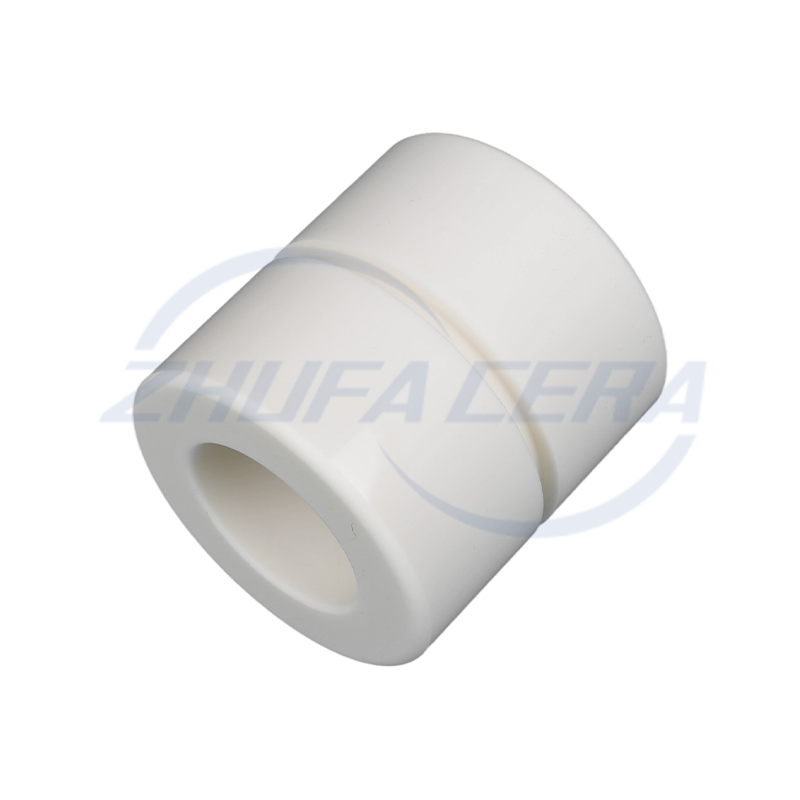

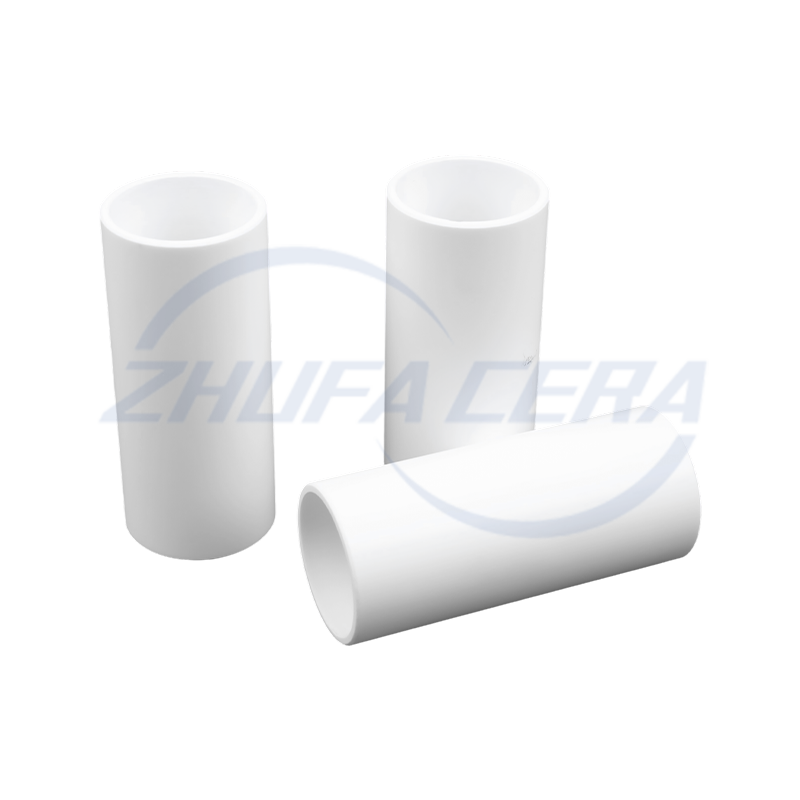

Alumina Ceramic Sleeve

Alumina Ceramic Sleeve is a high-performance ceramic component made of high-purity alumina (Al₂O₃) as the main raw material. It is widely used in electronics, machinery, chemical industry and aerospace fields. Its core advantage is that it can maintain structural stability at extreme temperatures above 1600°C while providing excellent electrical insulation performance. It is an ideal choice for high-temperature sealing, insulation protection and precision mechanical parts. Through the precision sintering process, the product achieves a balance between high density and low porosity, significantly extending its service life, and becoming a key component with both durability and reliability in the industrial field. Material propertiesAlumina ceramic sleeves are made of 95%-99% high-purity alumina raw materials, sintered at high temperature (1600-1800°C), and have the following characteristics:High temperature resistance and thermal stability: It can withstand a working temperature of 1200°C for a long time and a short-term temperature resistance of 1800°C. It is suitable for scenes such as high-temperature furnaces, heat exchangers and rocket nozzles.Electrical insulation performance: The volume resistivity is as high as 10¹⁴Ω·cm, which effectively prevents leakage in high-voltage environments and is often used for insulation packaging of semiconductor manufacturing equipment.Mechanical strength and wear resistance: The bending strength reaches 300-500MPa, and the hardness is close to corundum, which is suitable for high-wear scenarios such as bearings and sealing rings.Chemical corrosion resistance: Resistant to acid, alkali and organic solvent erosion, suitable for chemical pipeline insulation and corrosive fluid transmission systems.Manufacturing processThe product achieves high-precision dimensional control (tolerance ±0.01mm) through dry pressing or isostatic pressing technology, combined with surface polishing to ensure close fit with supporting components.Typical applicationsElectronics industry: As an insulating bushing for wafer processing equipment, it ensures the precision of semiconductor manufacturing.Mechanical engineering: Used for high-temperature pump body seals and valve guide sleeves to reduce friction loss.Energy field: Provide radiation-resistant and neutron-resistant structural support in nuclear reactors and fuel cells.

-

Read More

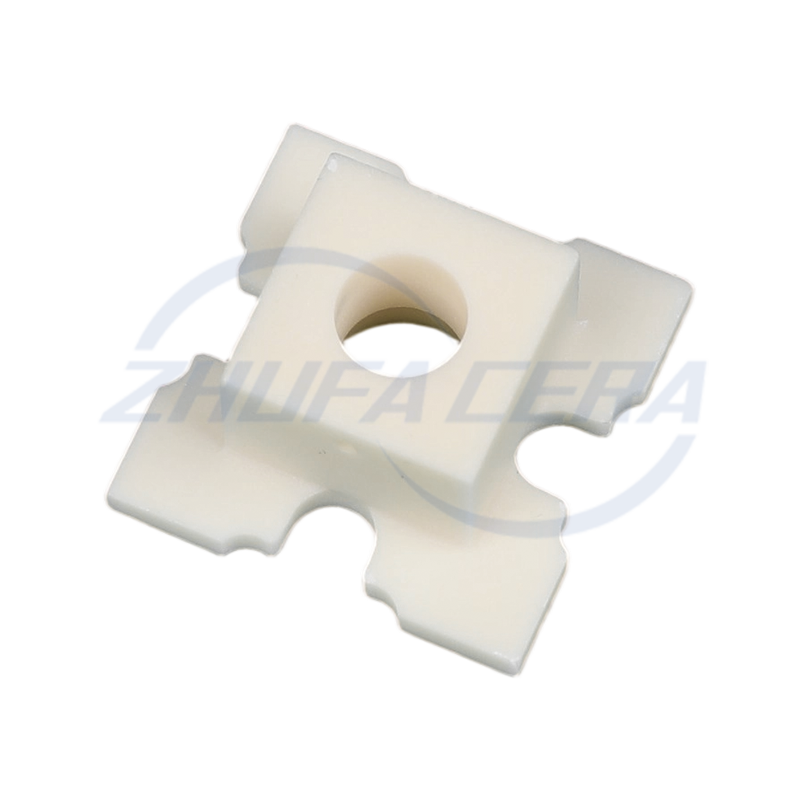

Alumina Ceramic Suction Cup Plate

Oxalumina Ceramic Suction Cup Plate is a revolutionary product in the field of precision handling systems. It is made of α-alumina ceramic (α-Al₂O₃) with a purity of ≥99.9%, combined with an engineered porous structure to achieve optimal vacuum distribution. Compared with traditional metal or polymer suction cups, this ceramic solution completely eliminates the risk of particle contamination, while being able to withstand extreme temperatures (1750°C continuous operation) and corrosive environments. Its unique microstructure (2-5μm uniform pore size, 3.89g/cm³ density) ensures submicron flatness (surface roughness Ra≤0.1μm), making it the only professional suction cup platform that can handle 300mm semiconductor wafers with a suction accuracy of ±0.1μm. 1. Breakthrough in material performanceThermal stability: no deformation in 800°C thermal shock cycles, and a service life 5 times longer than that of alloy suction cups (high temperature process environment).Chemical resistance: 1-year weight loss of 30% sulfuric acid immersion is less than 0.01g, suitable for battery electrolyte operation and chemical vapor deposition process.Insulation performance: The breakdown field strength reaches 40kV/mm, ensuring safe operation in the plasma etching chamber. 2. Engineering design innovationPorosity control: 40% porosity is achieved through gel injection molding process, and the 1-3μm pore wall structure prevents ultra-thin parts (≤50μm) from adsorption and deformation.Intelligent architecture: Built-in temperature sensor supports real-time thermal management from -196℃ to ultra-high temperature environment.

-

Read More

Alumina Ceramic Alumina Tube

Alumina Ceramic Alumina Tube is a high-performance ceramic tube made of high-purity alumina (Al₂O₃) as the main raw material. It is widely used in industrial scenarios with high temperature, corrosion resistance and high insulation requirements. Compared with similar ceramic tubes (such as silicon nitride or silicon carbide tubes), Alumina Ceramic Alumina Tube achieves a better balance between cost-effectiveness and comprehensive performance. Its core advantages are: high hardness (Mohs hardness level 9), temperature resistance (long-term use temperature can reach 1600℃), chemical corrosion resistance (resistance to acid, alkali and molten metal corrosion) and excellent electrical insulation (volume resistivity>10¹⁴Ω·cm). These characteristics make it an indispensable key material in the fields of electronics, chemical industry, metallurgy and aerospace. Product DetailsMaterial CharacteristicsAlumina Ceramic Alumina Tube uses ≥99% pure alumina raw materials, and is sintered at high temperature (1600-1800℃) to form a dense crystalline structure with low porosity (<1%), ensuring mechanical strength and thermal stability. Its low thermal expansion coefficient (7.2×10⁻⁶/℃) can effectively reduce the risk of deformation under high temperature. Manufacturing ProcessThe product achieves precise dimensional control (tolerance ±0.1mm) through dry pressing or isostatic pressing technology, and the surface is ground and polished to a roughness of less than Ra0.2μm, meeting high-precision assembly requirements. Application FieldsElectronic Industry: As an insulating bushing or high-temperature circuit substrate, it is suitable for power semiconductor packaging and vacuum electronic devices.Chemical Industry: Used for corrosive fluid delivery pipelines, reactor linings and catalyst carriers.Medical Equipment: Manufacture of high-temperature sterilization containers and biocompatible components.Metallurgical industry: used as metal melting crucible or thermocouple protection tube to resist molten metal corrosion.Environmental protection and durabilityThe product is lead-free, cadmium-free, RoHS-compliant, and has a service life of more than 10 years, significantly reducing replacement frequency and maintenance costs.

-

Read More

Custom Shape Alumina Ceramic Components

Custom Shape Alumina Ceramic Components are a type of high-performance structural parts in the field of advanced ceramics that are customized according to specific needs. Compared with standardized alumina ceramic products, the core difference is that they can achieve precise molding of complex geometric shapes through precision machining technology, while maintaining the inherent high hardness (HRA ≥ 85), high temperature resistance (operating temperature up to 1600°C), chemical corrosion resistance and excellent electrical insulation properties of alumina ceramics. This type of product is specially developed to solve non-standard design problems in the industrial field, and is particularly suitable for scenarios with strict requirements on material properties and structural adaptability. Alumina ceramic special-shaped parts combine computer-aided design (CAD) and numerical control machining (CNC) technology to achieve complex shapes from two-dimensional planes to three-dimensional structures, with a minimum machining accuracy of ±0.01mm. The surface finish of the product can reach Ra0.2μm, which effectively reduces friction loss and improves sealing performance. Its material purity (Al₂O₃ content ≥ 95%) ensures dimensional stability for long-term use, and it performs outstandingly in the fields of semiconductor equipment, aerospace propulsion systems, medical implants, etc. Typical applications include: High-precision sensor base: Thermal stress buffering by using low thermal expansion coefficient (7.2×10⁻⁶/℃)Plasma-etched chamber lining: High density (3.9g/cm³) to resist chemical erosionArtificial joint connection parts: Biocompatibility certification (USP Class VI) to meet medical needs

-

Read More

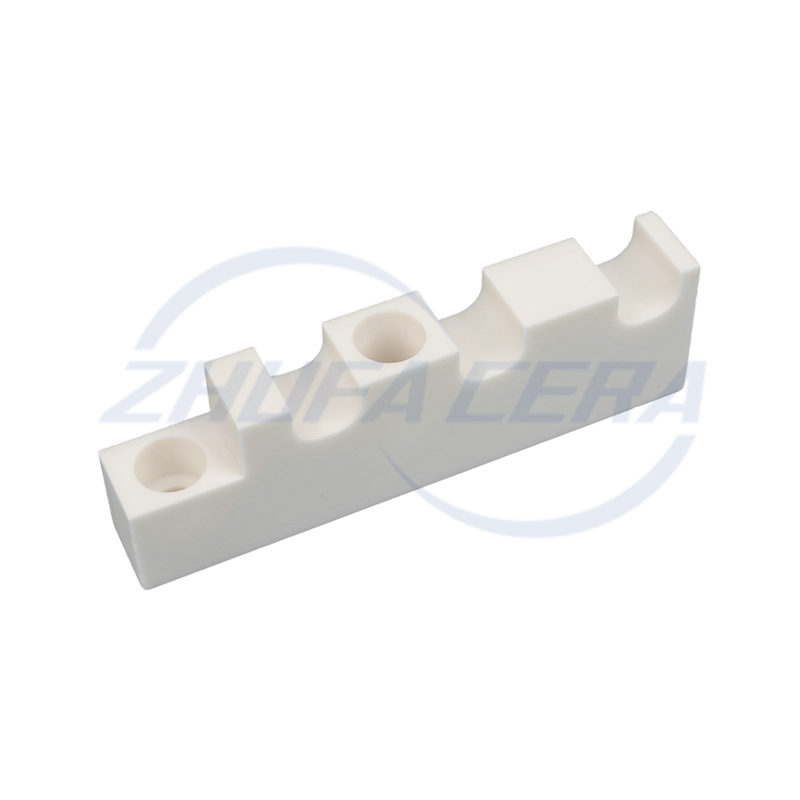

Custom Shape Alumina Ceramic Block

Custom Shape Alumina Ceramic Block is a high-performance customized ceramic component designed to meet specific industrial needs. The core difference of this product compared to the standard alumina ceramic block in the same category is its customizable shape. Standard blocks are usually limited to simple geometric shapes such as rectangles or circles, while custom alumina ceramic blocks can accurately manufacture complex contours such as special-shaped surfaces, holes or asymmetric structures according to customer requirements. In addition, alumina ceramics themselves have excellent wear resistance, high hardness and high temperature resistance (operating temperature can reach 1600°C), as well as excellent chemical stability, making it not easy to corrode or deform in harsh environments. This makes Custom Shape Alumina Ceramic Block outstanding in reducing maintenance costs and extending service life, especially suitable for fields requiring high precision and reliability.

-

Read More

Custom Shape Alumina Ceramic Disc

Custom Shape Alumina Ceramic Disc is a customized ceramic component designed for specific industrial applications. Different from standard disc products, its core advantage lies in the flexibility of geometric shapes. Made of high-purity alumina (Al₂O₃) material, this product can be precisely customized to non-standard shapes such as polygons, holes or complex contours according to customer needs, so as to achieve seamless adaptation in scenarios with limited space or high integration requirements. Compared with standard ceramic discs in the same category, Custom Shape Alumina Ceramic Disc significantly improves application adaptability. For example, in electronic packaging or mechanical systems, it can reduce the number of components, simplify the assembly process, and enhance overall performance. The core attraction of Custom Shape Alumina Ceramic Disc is its high customization capability, which allows users to design geometric shapes (such as special-shaped edges, internal grooves or asymmetric structures) according to specific application requirements, thereby optimizing space utilization and functional integration. In addition, its material properties provide long-term reliability and reduce the risk of system failure.

-

Read More

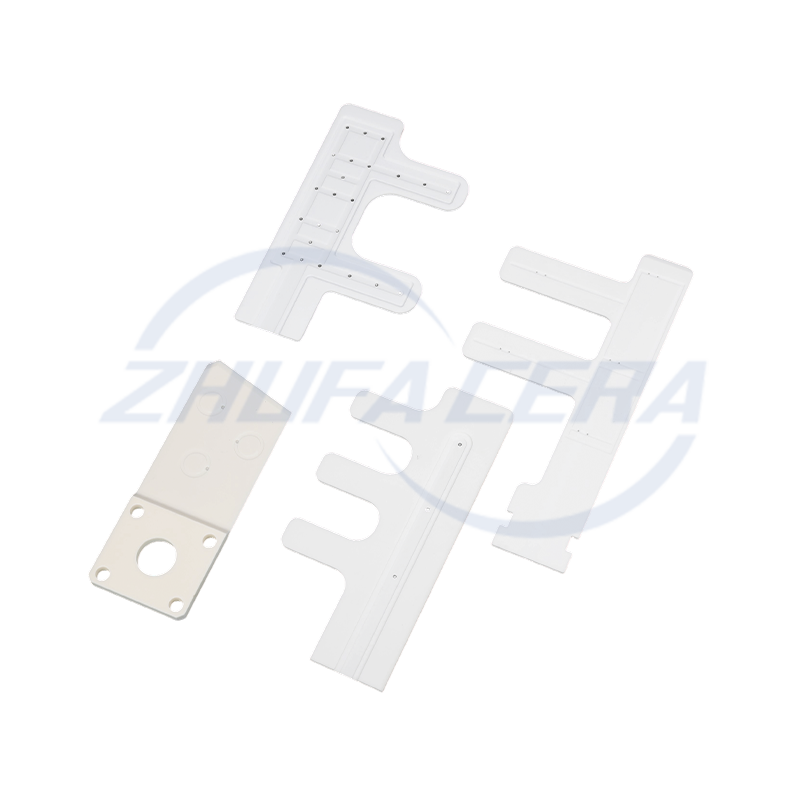

Custom Shape Alumina Ceramic Bracket

Custom Shape Alumina Ceramic Bracket is a high-performance structural part made of high-purity alumina raw materials through precision molding technology. Compared with traditional metal brackets or standard ceramic products, this product breaks through the limitations of regular geometric shapes through customized special-shaped design, and can accurately match the non-standard installation requirements in complex equipment. Its core advantage lies in combining the high temperature resistance (operating temperature up to 1600℃), corrosion resistance, and high insulation characteristics of alumina ceramics with personalized shapes, showing irreplaceable application value in high-end fields such as semiconductor manufacturing, aerospace, and medical equipment.

-

Read More

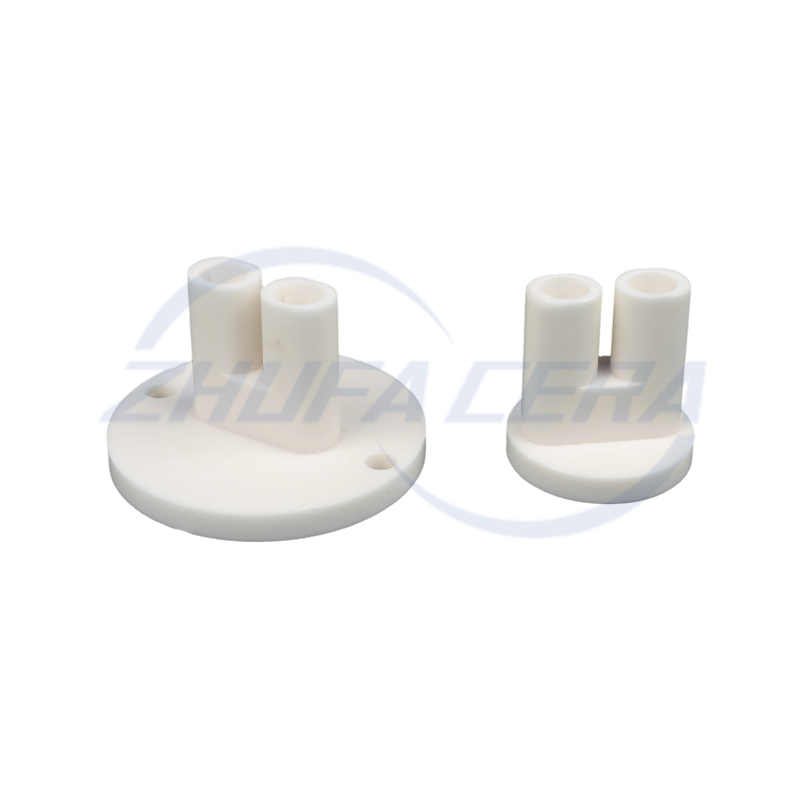

Custom Shape Alumina Ceramic Base

Custom Shape Alumina Ceramic Base is a non-standard customized ceramic base made of high-purity alumina material. Compared with traditional standard geometric ceramic parts, this product realizes the molding of complex three-dimensional contours through precision machining technology, which can accurately match the installation requirements of special equipment or devices. Its core advantage lies in combining the excellent physical properties of alumina ceramics (such as high hardness, high temperature resistance, and insulation) with personalized structural design. While maintaining the intrinsic properties of the material, it breaks through the shape limitations of conventional ceramic products and provides a more flexible solution for the field of high-end equipment manufacturing. Material properties: Using alumina ceramics with a purity of more than 99.7%, Vickers hardness of 1800HV, operating temperature range of -196℃ to 1600℃, volume resistivity>10^14Ω·cm, with both mechanical strength and electrical insulation.Precision molding: Using CNC machining and laser engraving technology, it can achieve dimensional accuracy control of ±0.02mm, and support the processing of complex curved surfaces, special-shaped holes and microstructures.Customized design: Reverse engineering optimization is performed based on the 3D model provided by the customer to ensure that the assembly gap is ≤0.05mm, which is particularly suitable for scenes with strict requirements on installation accuracy, such as semiconductor equipment, laser instruments, and medical equipment.Surface treatment: Mirror polishing (Ra<0.1μm), coating adhesion (metallization treatment) and other processes are provided to meet the friction coefficient and conductivity requirements under different working conditions.

-

Read More

Alumina Ceramic Disc Cover

Alumina Ceramic Disc Cover is a high-performance industrial component made of high-purity alumina (Al₂O₃) material, designed for high-temperature, corrosion-resistant and high-insulation scenarios. Compared with similar products made of ordinary ceramic or metal materials, its core advantage lies in the natural characteristics of alumina ceramics: hardness close to corundum (Mohs hardness level 9), low thermal expansion coefficient (about 7×10⁻⁶/℃), and excellent chemical stability (resistant to acid, alkali and organic solvent corrosion). These characteristics make it an upgraded alternative to traditional materials in the fields of electronic packaging, high-temperature sealing, and mechanical wear-resistant parts. Material characteristics: High-purity alumina (≥95%) ensures low dielectric loss (εr=9-10) and high body resistivity (10¹⁴Ω·cm), suitable for insulation protection of 5G communication modules and semiconductor equipment.Heat resistance: It can work stably below 1600℃ for a long time, and can withstand temperatures of 1800℃ in the short term. It is suitable for scenarios such as aviation engine sealing and high-temperature valve covers in the metallurgical industry.Wear and corrosion resistance: The surface hardness reaches HRA88, and the service life is 3-5 times longer than that of metal covers in sanding and corrosive fluid environments. Typical applications include chemical pump body seals and wear-resistant parts of mining machinery.Precision adaptation: ±0.01mm dimensional accuracy is achieved through CNC processing, compatible with standard flange interfaces, and can directly replace imported parts to reduce equipment maintenance costs.

-

Read More

Alumina Ceramic Needle Roller

Alumina Ceramic Needle Roller is a precision rolling component made of high-performance ceramic material, which is widely used in mechanical transmission systems. Compared with traditional steel needle rollers, alumina needle rollers have higher wear resistance, high temperature resistance and corrosion resistance, and can provide long-term stable performance in extreme working environments. The advantage of this material is its high hardness and low friction coefficient, which makes it more superior in high-speed running systems, especially suitable for applications requiring high precision and long-term use. Alumina Ceramic Needle Roller uses high-quality alumina ceramic material with excellent physical properties. Due to its high density and low expansion coefficient, it can maintain a stable structure and function in high temperature or humid environment, avoiding deformation problems caused by temperature changes. Its smooth surface and low friction coefficient can effectively reduce energy loss and improve work efficiency. In addition, alumina needle rollers have strong acid and alkali corrosion resistance and are suitable for applications in a variety of chemical environments. Alumina needle rollers are widely used in automobiles, aviation, precision instruments and other fields, especially in systems that require wear resistance, corrosion resistance and high-precision transmission. Its light weight and high strength make it provide a long service life even under heavy loads, thus reducing maintenance costs and improving the overall reliability of the equipment.

Alumina Ceramics is a high-performance ceramic material made of alumina as the main raw material. According to the different alumina content, it can be divided into low-alumina ceramics (alumina content of 30% - 50%), medium-alumina ceramics (alumina content of 50% - 75%) and high-alumina ceramics (alumina content of more than 75%, of which 95 ceramics and 99 ceramics are common high-purity types). Different types of Alumina Ceramics have their own characteristics: low-alumina ceramics have low cost and moderate mechanical strength, which are suitable for scenes with low performance requirements; medium-alumina ceramics have certain improvements in strength, hardness and wear resistance, and have both cost-effectiveness and practicality; high-alumina ceramics show excellent performance, not only with high hardness (Mohs hardness can reach level 9, second only to diamond), but also with excellent high temperature resistance (can work stably in high temperature environments above 1600°C), good chemical stability (strong acid and alkali corrosion resistance) and excellent insulation performance, and Alumina Ceramics It has a wide range of uses. In the electronics industry, high-alumina ceramics are often used as integrated circuit substrates, electron tube sockets, etc., and their good insulation and thermal conductivity ensure the stable operation of electronic components; in the field of mechanical manufacturing, it can be used to make wear-resistant parts such as bearings and seals to extend the service life of mechanical equipment; in the chemical industry, due to its corrosion resistance, it is often used to make reactor linings, pipes, etc.; in addition, in the medical field, high-purity Alumina Ceramics can also be used to make implants such as artificial joints with good biocompatibility. In short, Alumina Ceramics plays an irreplaceable role in multiple industries with its diverse classification and excellent comprehensive performance. It is one of the important high-performance materials in modern industry.

-

Ceramic materials play a crucial role in modern industrial applications, from electronics to biomedical devices. Among the widely used advanced ceramics, ZTA Ceramics and ZrO₂ Ceramics stand out for their exceptional mechanical, thermal, and chemical properties. Understanding the differences between these two materia

READ MORE -

The Influence of Zirconia Content on the Performance of ZTA Ceramics Zirconia Toughened Alumina (ZTA) ceramics are widely used in industries where superior mechanical strength and thermal stability are critical. The combination of zirconia (ZrO2) and alumina (Al2O3) results in a material with enhanced toughness, making

READ MORE

-

Black silicon carbide ceramic ring is a high-performance engineered ceramic assembly made

See Details -

Zirconia Ceramic Rod is a high-performance ceramic material rod, mainly made of zirconium

See Details -

Blue zirconia ceramic sheets are precision components made of advanced zirconia ceramic

See Details -

This blue zirconia ceramic pin is made of advanced zirconia ceramic material, providing

See Details -

Zirconia Ceramic Gear is made of zirconium oxide ceramic material, which has excellent hig

See Details -

Zirconia Ceramic Guide Rail is a high-performance precision mechanical component made of z

See Details

Alumina Ceramics: Key Insights into Manufacturing, Performance, and Industrial Applications?

What Core Characteristics Make Alumina Ceramics a Go-To Material for Precision Industries?

Alumina ceramics, primarily composed of aluminum oxide, stand out as a cornerstone of advanced ceramic materials due to their exceptional inherent properties. These include high hardness (second only to diamond among common industrial materials), excellent electrical insulation, resistance to high temperatures (withstanding over 1,600°C in many cases), and strong corrosion resistance against most chemicals. For manufacturers focused on precision components, these traits are non-negotiable—and Zhejiang Zhufa Precision Ceramics Technology Co., Ltd. amplifies these advantages through strict process control. As a source factory specializing in new ceramic materials, the company ensures each alumina ceramic part retains consistent performance, aligning with industrial demands for reliability in harsh operating environments.

How Does Modern Manufacturing Ensure High-Quality Alumina Ceramics?

The manufacturing of alumina ceramics is a precision-driven process, with each step directly impacting final product quality. The typical workflow includes raw material purification (to reduce impurities that weaken performance), forming (such as dry pressing, cold isostatic pressing, or injection molding for complex shapes), high-temperature sintering (to achieve dense, stable ceramic bodies), and precision finishing (for tight dimensional tolerances).

Zhejiang Zhufa supports this workflow with a 30,000㎡ state-of-the-art manufacturing base, equipped with core machinery like high-temperature sintering furnaces, CNC engraving machines, and centerless grinders. This end-to-end in-house production capability—from raw material processing to final inspection—allows the company to control every detail, whether for standard alumina parts or non-standard, small-batch prototypes. By adhering to technology-driven standards, it ensures the alumina ceramics meet the strict precision and performance requirements of industrial clients.

Which Industrial Sectors Rely Heavily on Alumina Ceramics, and Why?

Alumina ceramics’ versatility makes them indispensable across multiple high-demand industries, with applications tailored to their unique strengths:

Automotive & New Energy: Used in sensors, braking systems, and electronic control units, their wear resistance and insulation improve vehicle safety and durability—key for new energy and smart car development.

Photovoltaics: Applied in wafer cutting and high-temperature sintering processes, their heat resistance and wear resistance boost production efficiency and extend equipment life.

Petrochemicals: Integrated into pumps, valves, and seals, their corrosion resistance ensures reliable operation in complex chemical environments, reducing maintenance costs.

Semiconductors: Utilized in wafer handling and etching equipment, their high purity and thermal stability minimize pollution risks and maintain process accuracy.

Zhejiang Zhufa leverages its cross-industry expertise to tailor alumina ceramic solutions for these sectors, supporting both small-batch trials and large-scale delivery to meet diverse client needs.

What Advantages Do Customized Alumina Ceramic Services Offer, and How Does Zhejiang Zhufa Deliver Them?

Industrial clients often require alumina ceramics tailored to unique shapes, sizes, or performance specs—standard off-the-shelf products rarely suffice. Customized services address this by aligning materials and design with specific application goals, such as optimizing for extreme temperatures or tight dimensional precision.

Zhejiang Zhufa excels in this area by offering fully in-house customization, direct engineering support, and flexible production (from small-batch proofing to mass manufacturing). Its customer-centric service system includes end-to-end support: from collaborating on design optimization to shorten development cycles, to ensuring consistent lead times. This approach not only meets clients’ performance and efficiency needs but also helps enhance their market competitiveness.

-

Quick Links

Home Products About Us Services Technology News Contact Us -

Products

Ceramic Structural Parts Zirconia Ceramics Alumina Ceramics ZTA Ceramics Silicon Nitride Ceramics Silicon Carbide Ceramics Ceramic Injection Molded Parts -

About Us

Factory Tour Honor FAQ -

Contact info

+86-188 8878 5188zf@zfcera.comNo. 1, Xinggong Road, Anchang Industrial Park, Keqiao District, Shaoxing City, Zhejiang Province, China -

Qrcode

中文简体

中文简体 русский

русский Español

Español عربى

عربى Português

Português 日本語

日本語 한국어

한국어